Trailer type polymer grouting system

A grouting system and polymer technology, applied in construction, infrastructure engineering and other directions, can solve problems such as hidden dangers, inability to meet the requirements of grouting equipment functions, safety of river embankments, etc., to achieve reliable performance, strong practicability and The effect of irreplaceable and convenient hauling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

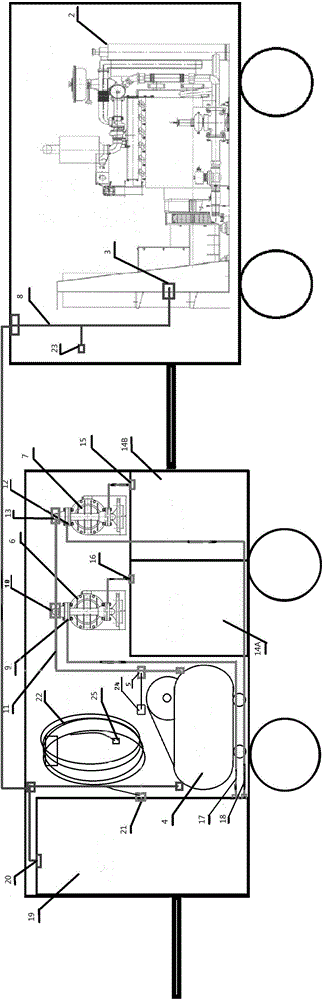

[0017] Such as figure 1 The trailer-type polymer grouting system shown includes a trailer I1A, on which an air compressor 4 is installed, the air inlet 10 of the pneumatic diaphragm pump I6 is connected to the air compressor 4 through an air rope 11, and the air compressor II7 of the pneumatic diaphragm pump The air inlet 13 is connected with the air compressor 4 through the air rope 11, the valve 5 is installed on the air rope 11, and the storage tank I14A and the storage tank II14B are also installed on the trailer I1A, and the storage tank I14A is connected with the pneumatic valve through the delivery pipe I16. Diaphragm pump Ⅰ6 is connected, storage tank Ⅱ14B is connected with pneumatic diaphragm pump Ⅱ5 through feeding pipe Ⅱ15, grouting ratio meter 19 is also installed on trailer Ⅰ1A, and the discharge port 9 of pneumatic diaphragm pump Ⅰ14A is connected with injector through feeding pipe Ⅲ17. The slurry proportioning instrument 19 is connected, the outlet 12 of the pne...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com