Heat exchange system and method for high-temperature semiconductor process equipment

A heat exchange system and semiconductor technology, applied in heat exchange equipment, heat exchanger types, indirect heat exchangers, etc., can solve problems such as failure to meet semiconductor process requirements, unstable air temperature, and impurities in wafers

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

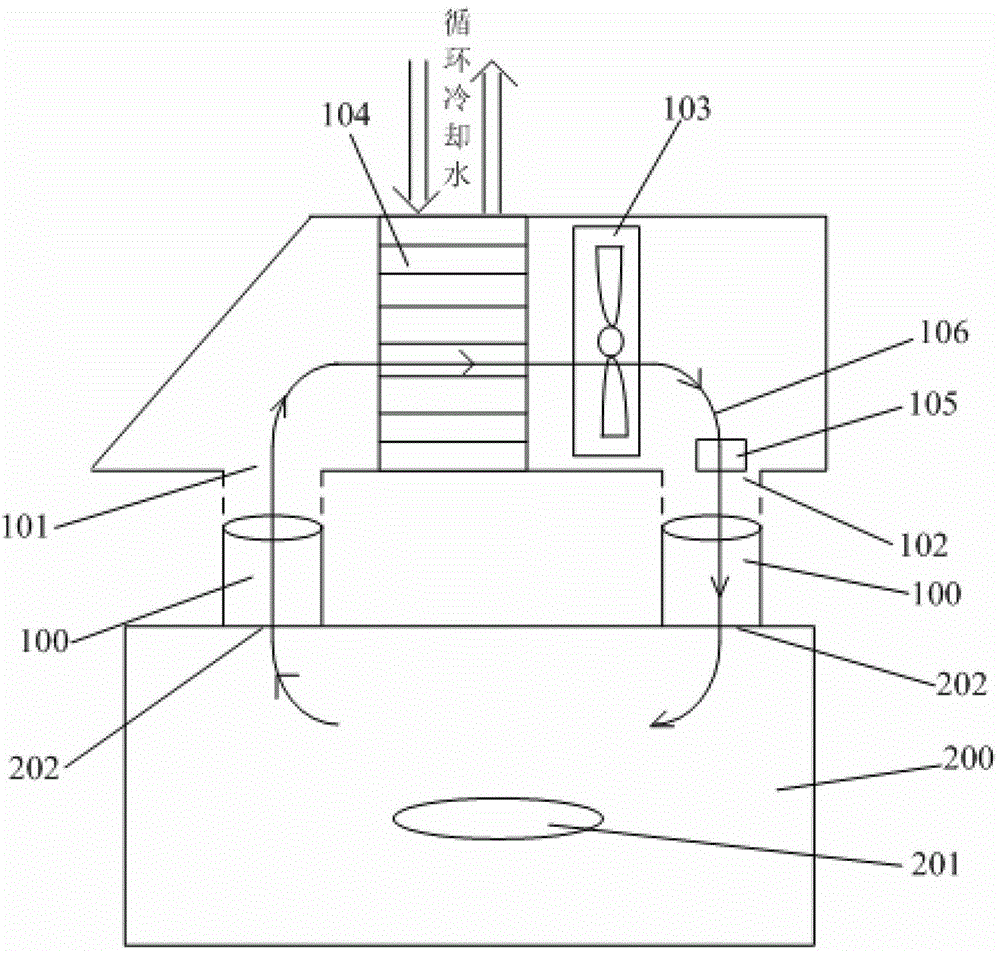

[0020] The following will combine figure 1 with figure 2 With a detailed description of the heat exchange system and method of the high-temperature semiconductor process equipment provided by the present invention, it can be considered that those skilled in the art can modify and polish it within the scope of not changing the spirit and content of the present invention.

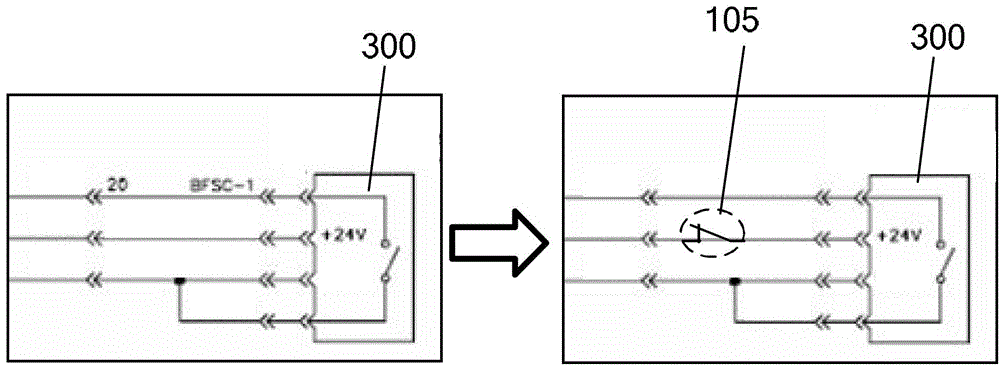

[0021] Please refer to figure 1 , this embodiment provides a heat exchange system for a high-temperature semiconductor process machine, which is used to connect with the two ventilation ports 202 of the reaction chamber 200, including the air inlet 101, the air outlet 102, the heat exchanger 104, and the The blower 103 of air outlet 102 and a thermal sensor 105, please refer to figure 1 In the air flow direction 106, after the hot air discharged from the reaction chamber 200 enters the air inlet 101, it passes through the heat exchanger 104, the thermal sensor 105 and the air outlet 102 in sequence, and th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com