Patents

Literature

51results about How to "Process impact" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

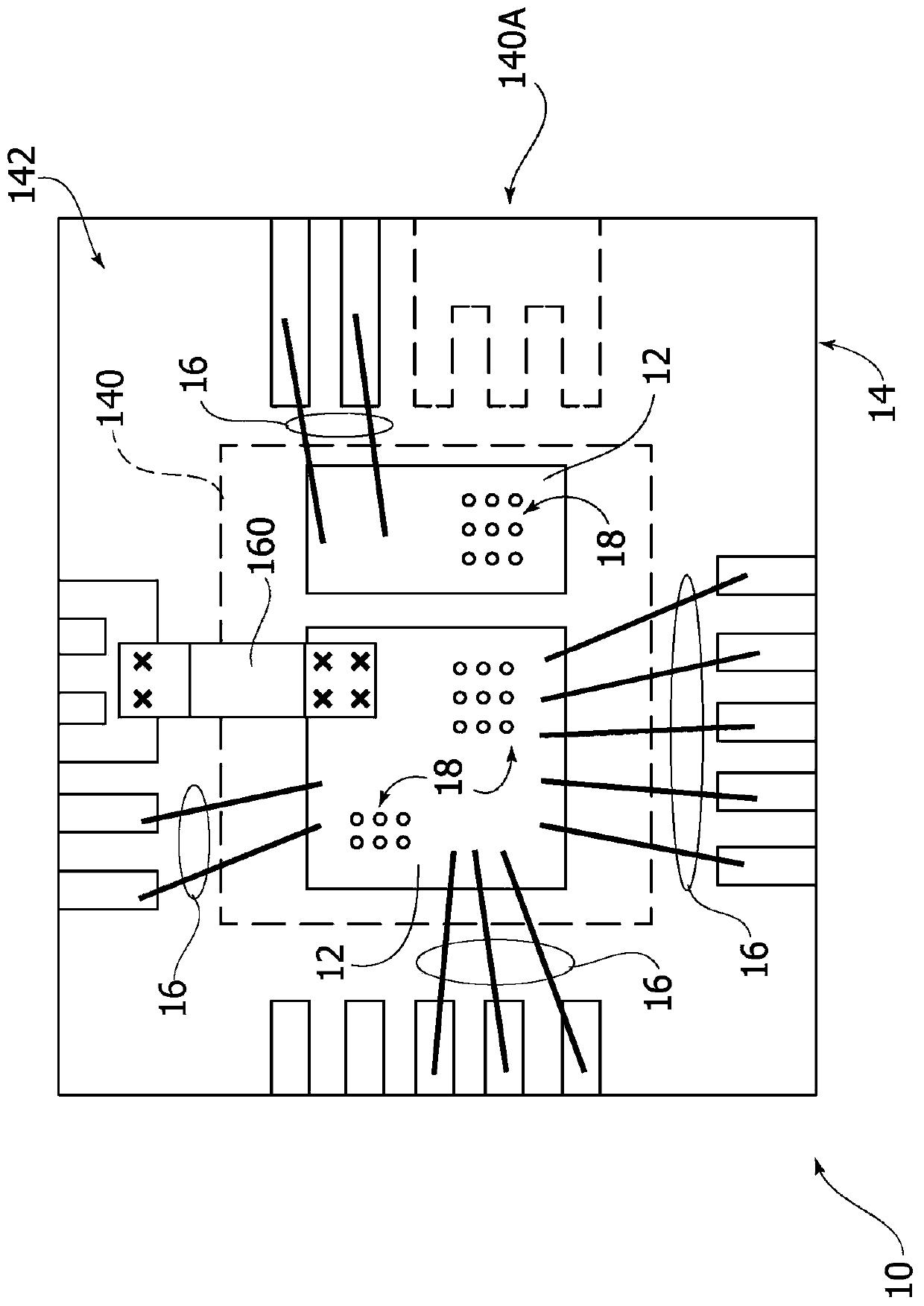

Wireless charging system and method for electric cars

ActiveCN104638694AImprove securityImprove reliabilityBatteries circuit arrangementsElectromagnetic wave systemPower batteryElectricity

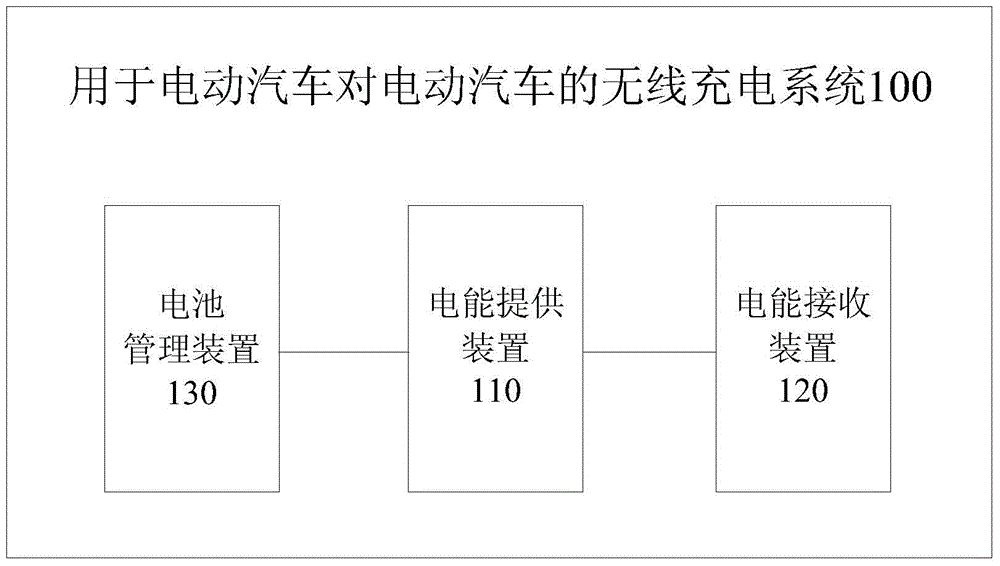

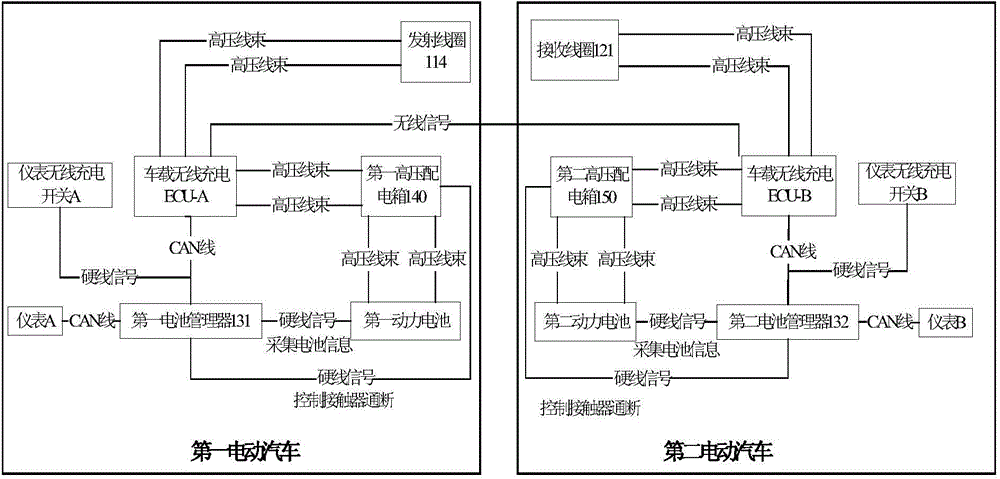

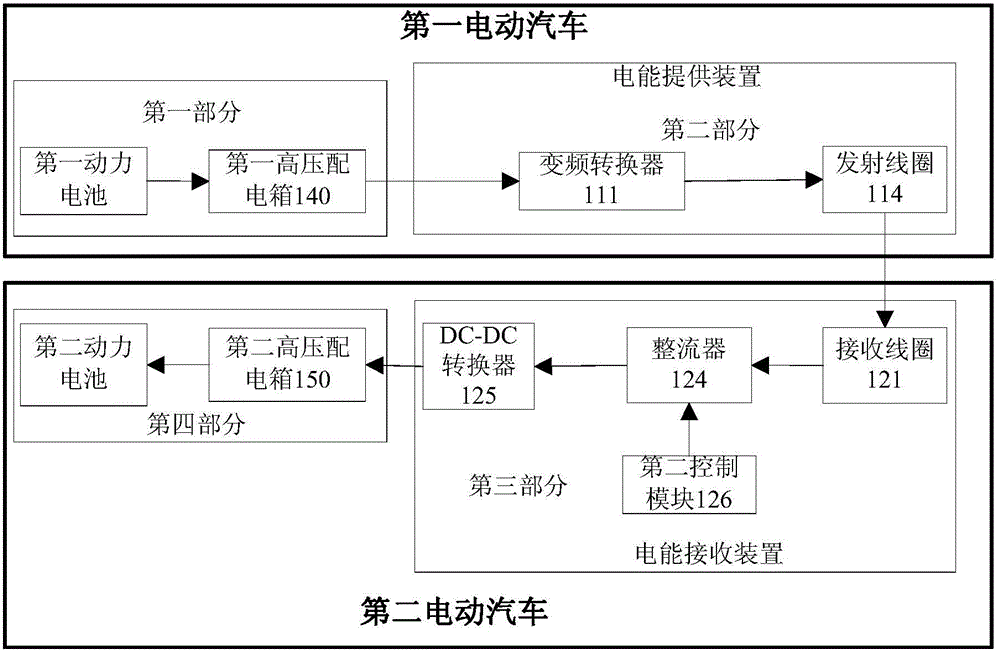

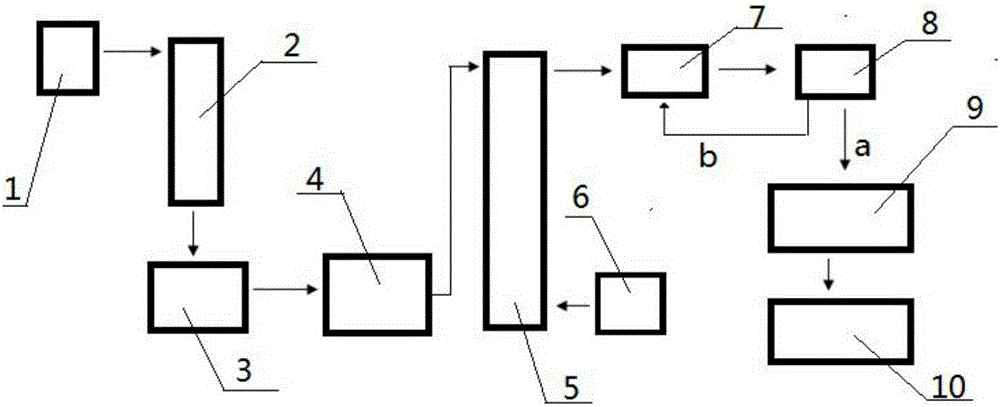

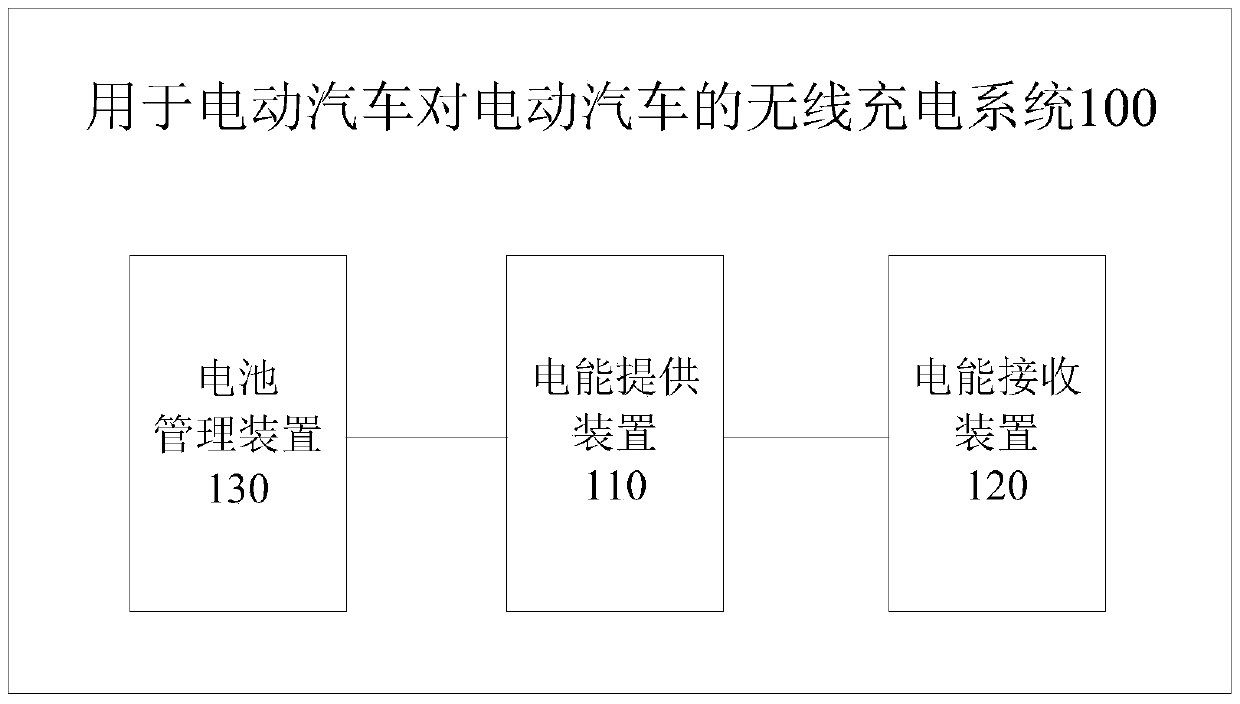

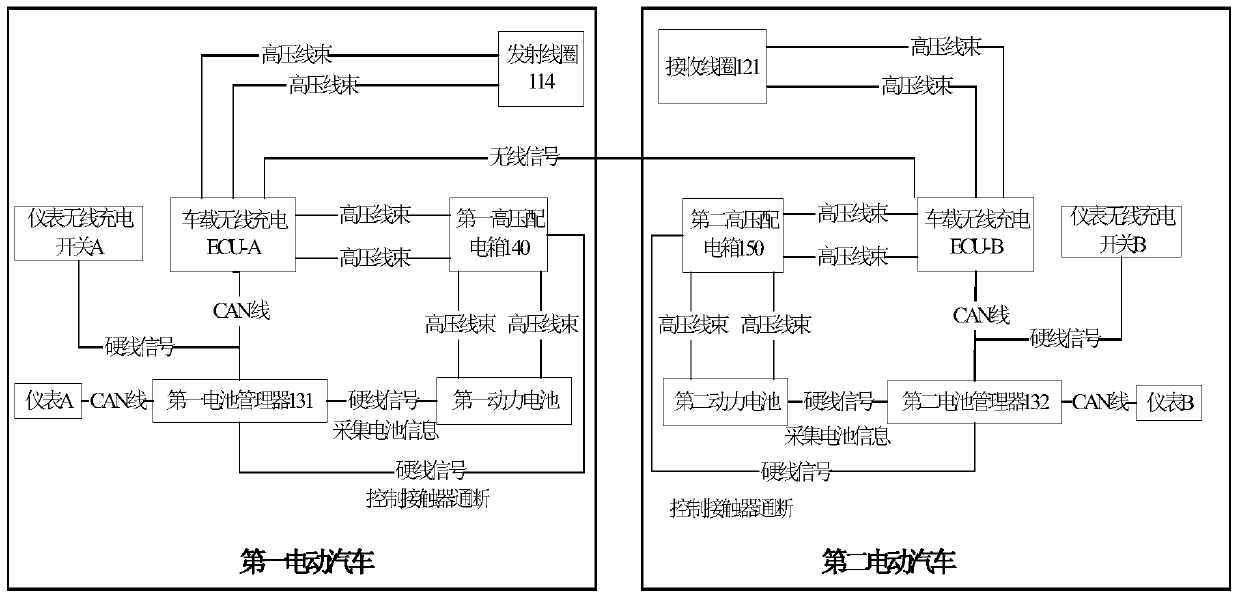

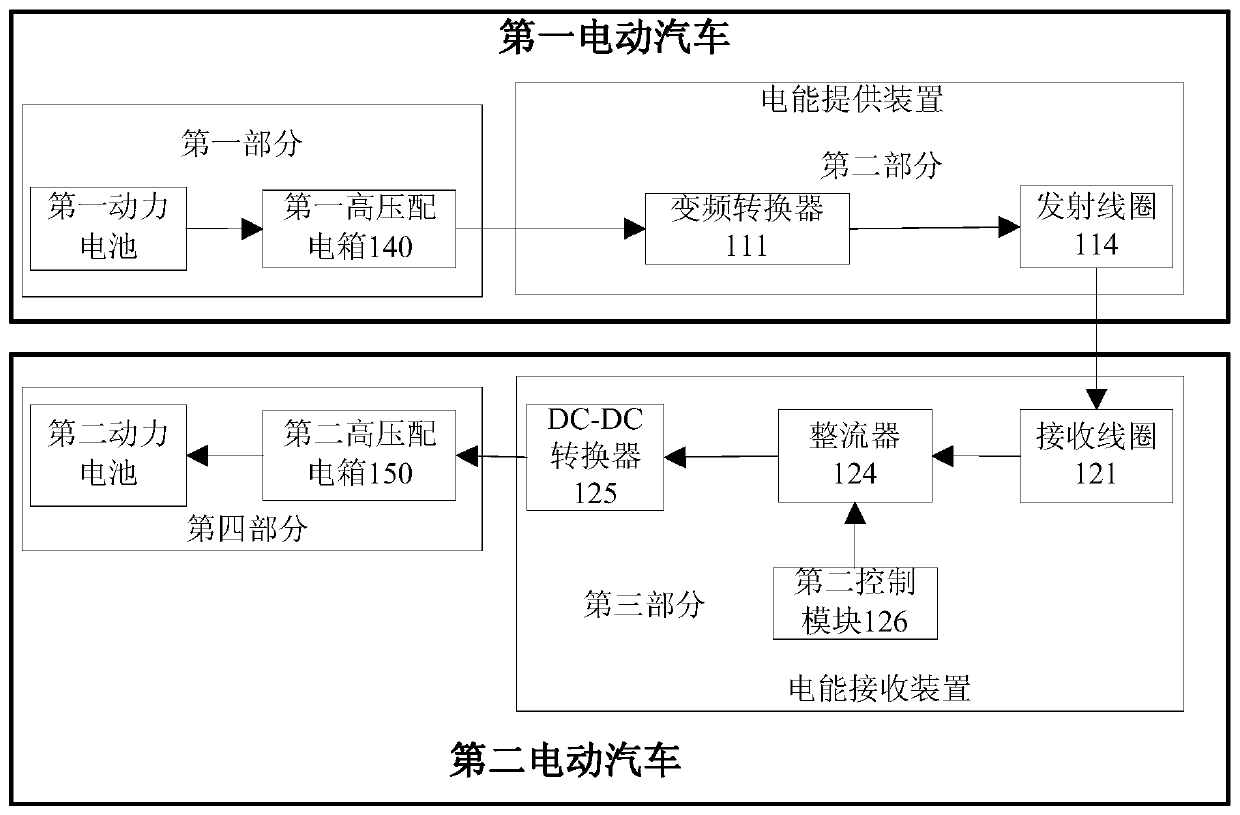

The invention discloses a wireless charging system for electric cars and a control method of the wireless charging system. The system comprises an electric energy providing device, an electric energy receiving device and a battery management device, wherein the battery management device comprises a first battery manager and a second battery manager, and the electric energy providing device is used for transmitting electric energy to the electric energy receiving device; the electric energy receiving device uses the electric energy provided by the electric energy providing device to charge a second power battery; the first battery manager is used for controlling the wireless charging flow of the electric energy providing device; the second battery manager is used for controlling the wireless charging flow of the electric energy receiving device. The wireless charging system has the advantages that wireless charging between the electric cars can be achieved, high safety and reliability are achieved, charging is simple and practicable, the service life of charging equipment can be prolonged by the wireless charging manner, and high applicability is achieved.

Owner:BYD CO LTD

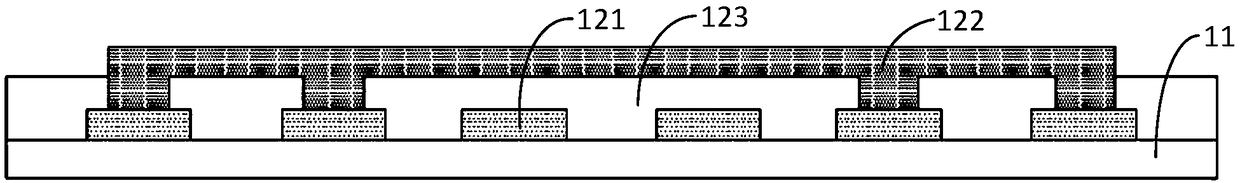

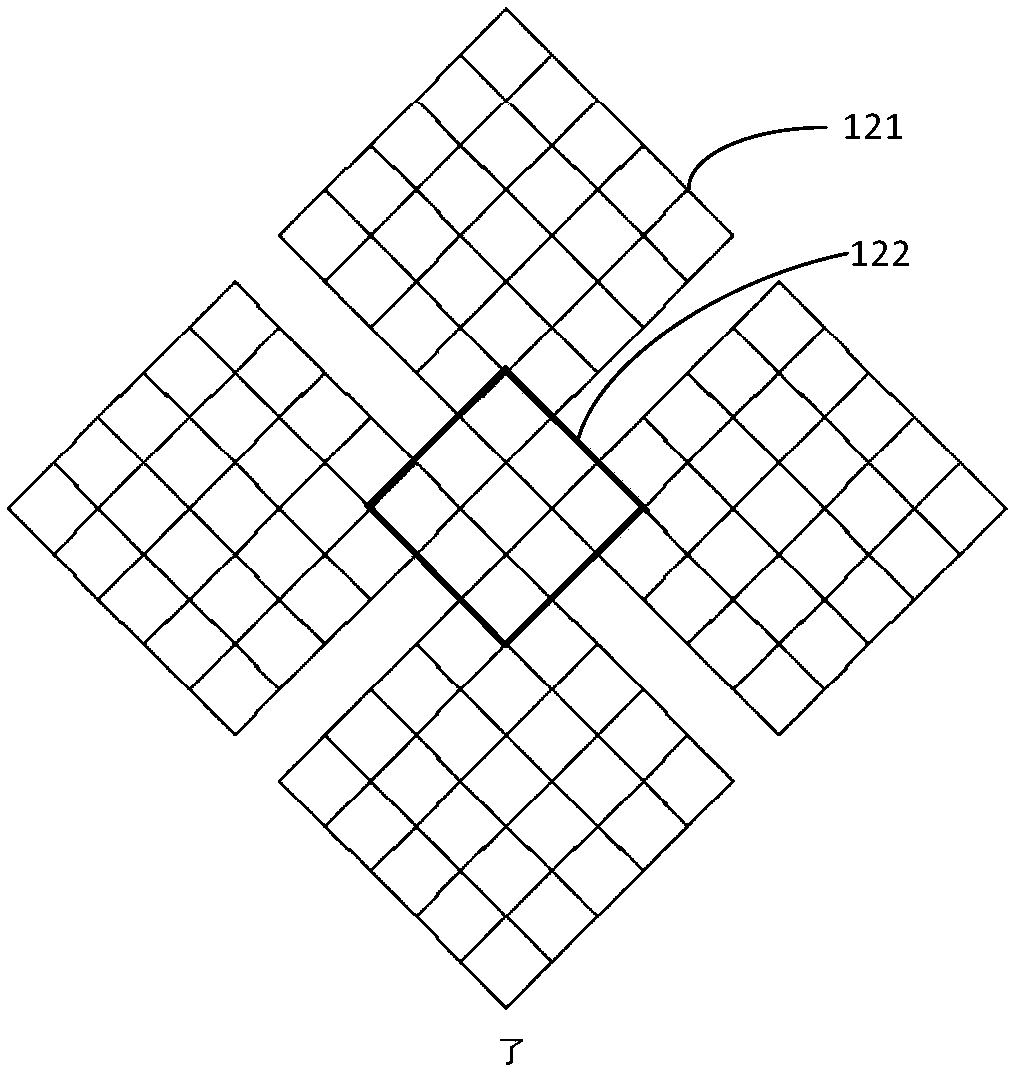

A touch display panel and a manufacturing method thereof

ActiveCN109407893AImprove product yieldProcess impactInput/output processes for data processingOrganic light emitting deviceLight-emitting diode

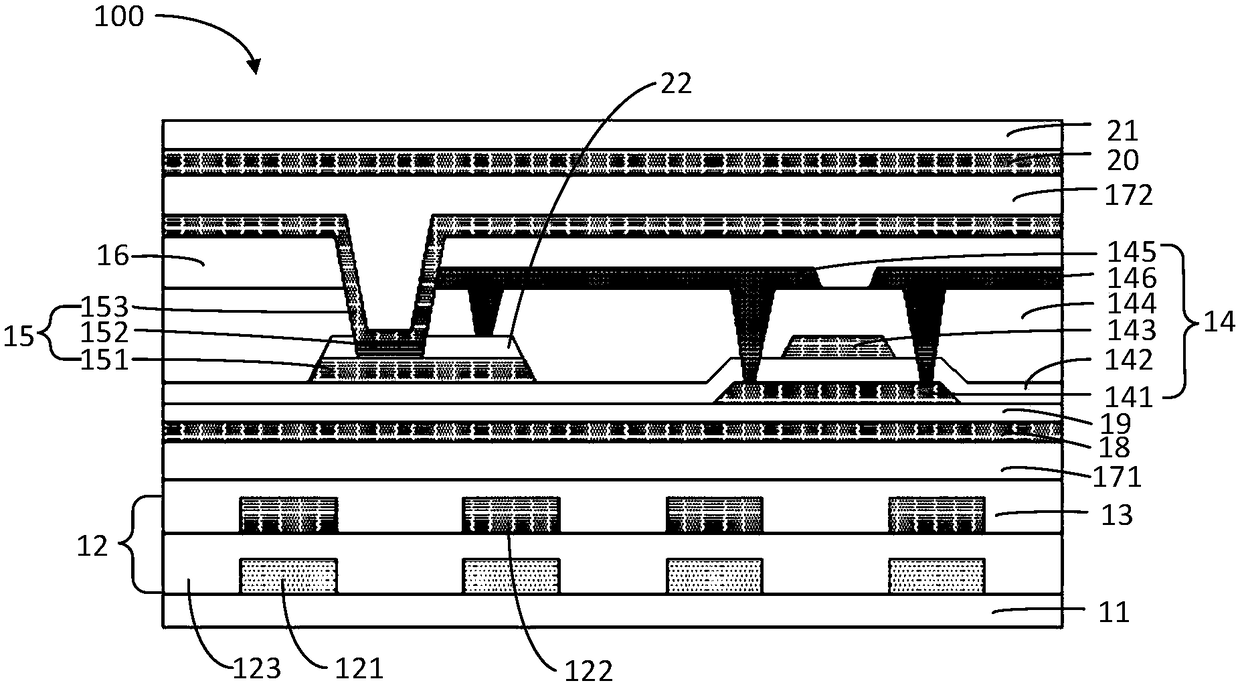

The invention provides a touch display panel and a manufacturing method. The touch display panel comprises a substrate, a touch layer, a protective layer, an array substrate and an organic light-emitting device. The touch layer comprises a touch pattern layer, a first insulating layer and a bridging layer. The organic light emitting device includes an anode, a cathode, and a light emitting layer disposed between the anode and the cathode. The touch layer is arranged between the substrate and the organic light-emitting device, and the touch layer is prepared first and then the organic light-emitting device is prepared, so that the process of the touch layer is not affected by the organic light-emitting device, and the product yield is improved.

Owner:WUHAN CHINA STAR OPTOELECTRONICS SEMICON DISPLAY TECH CO LTD

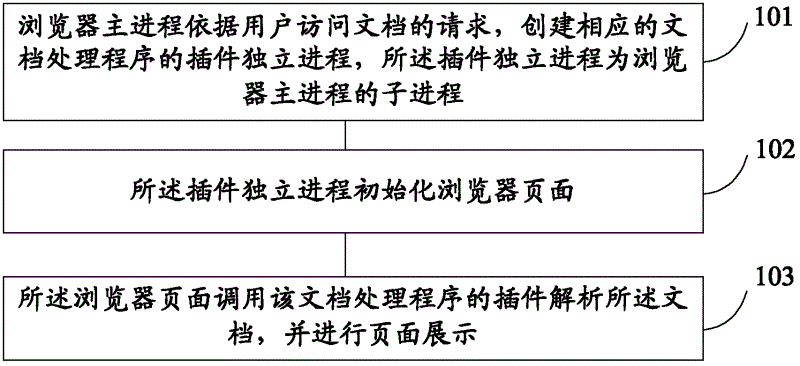

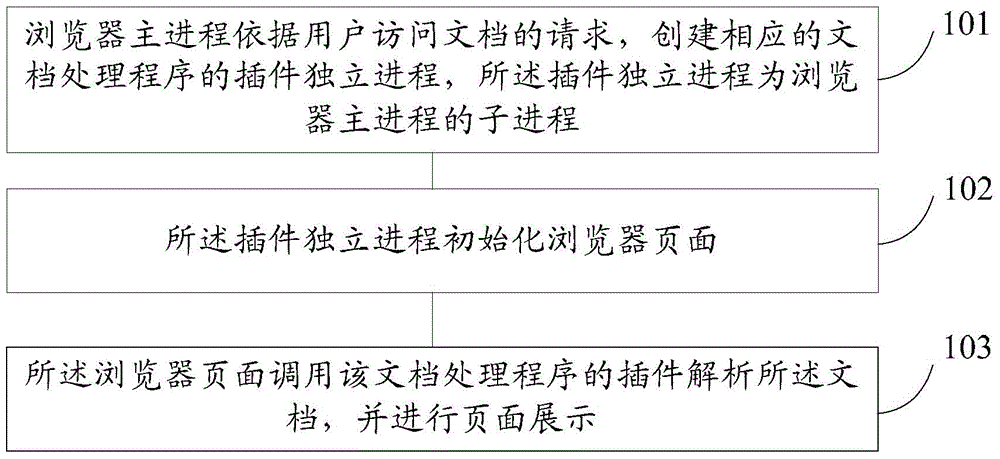

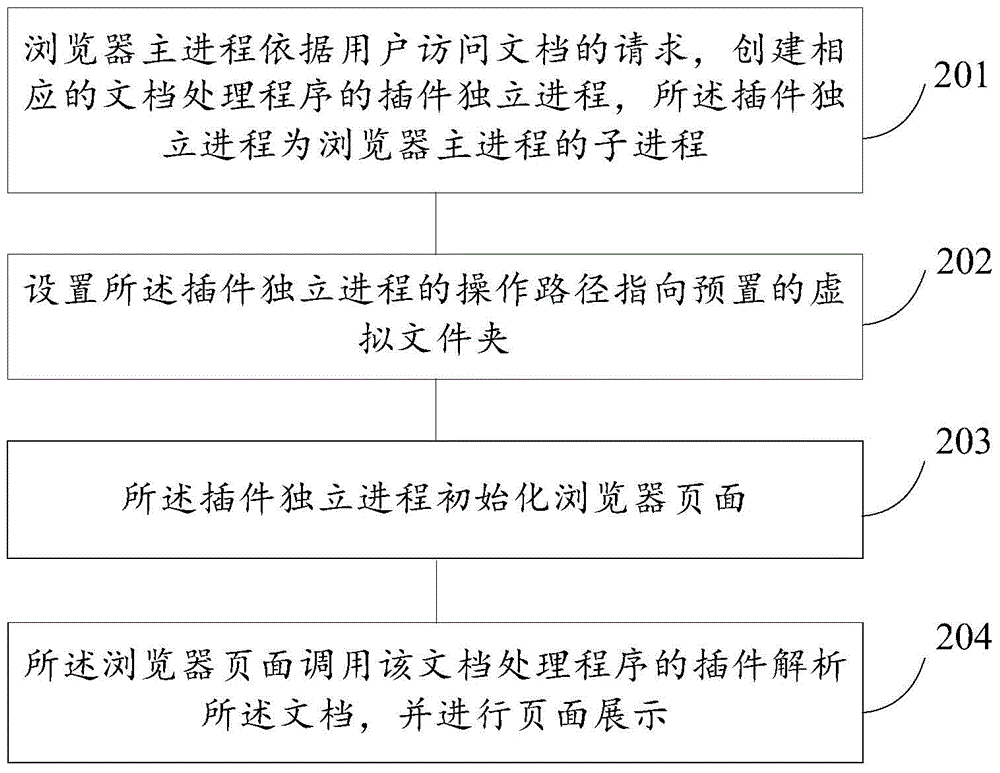

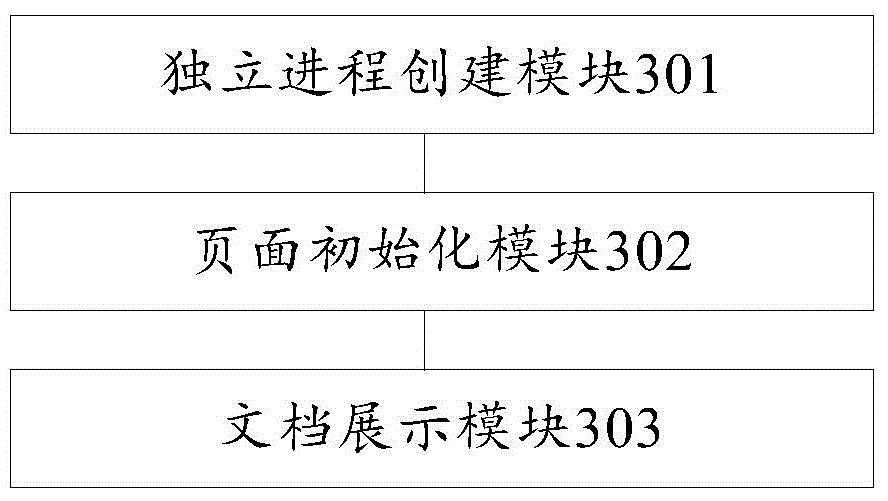

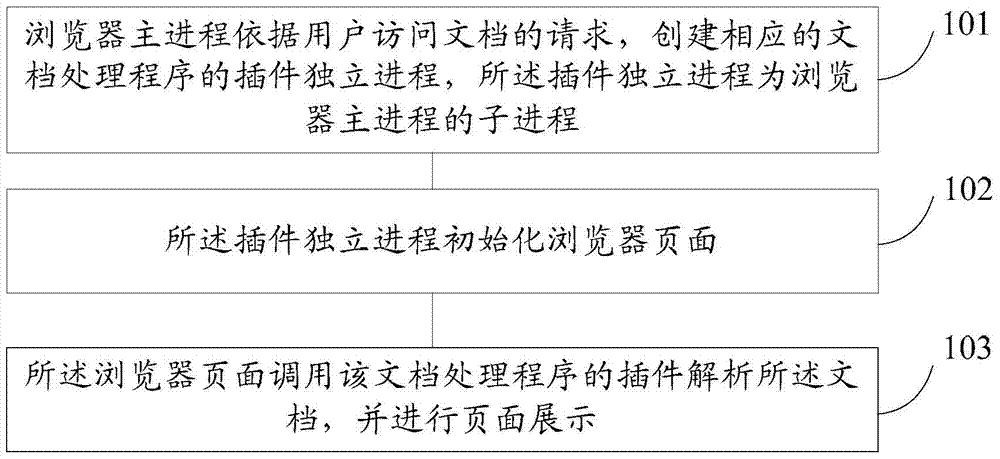

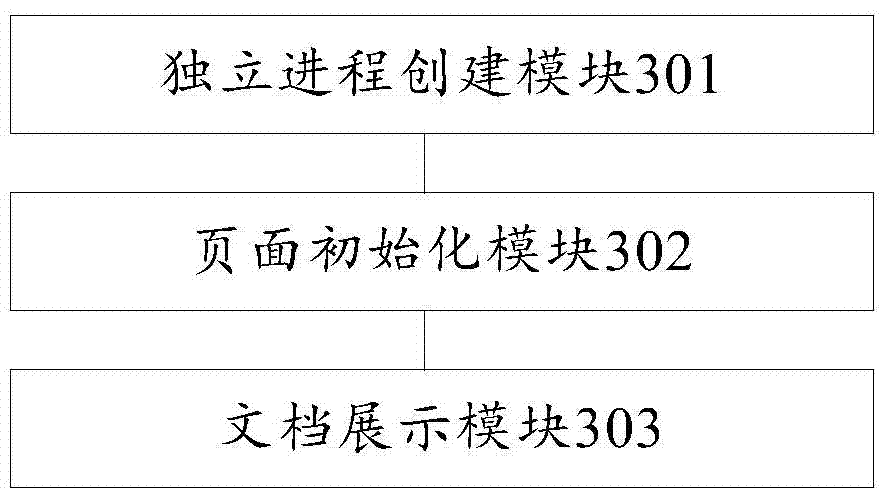

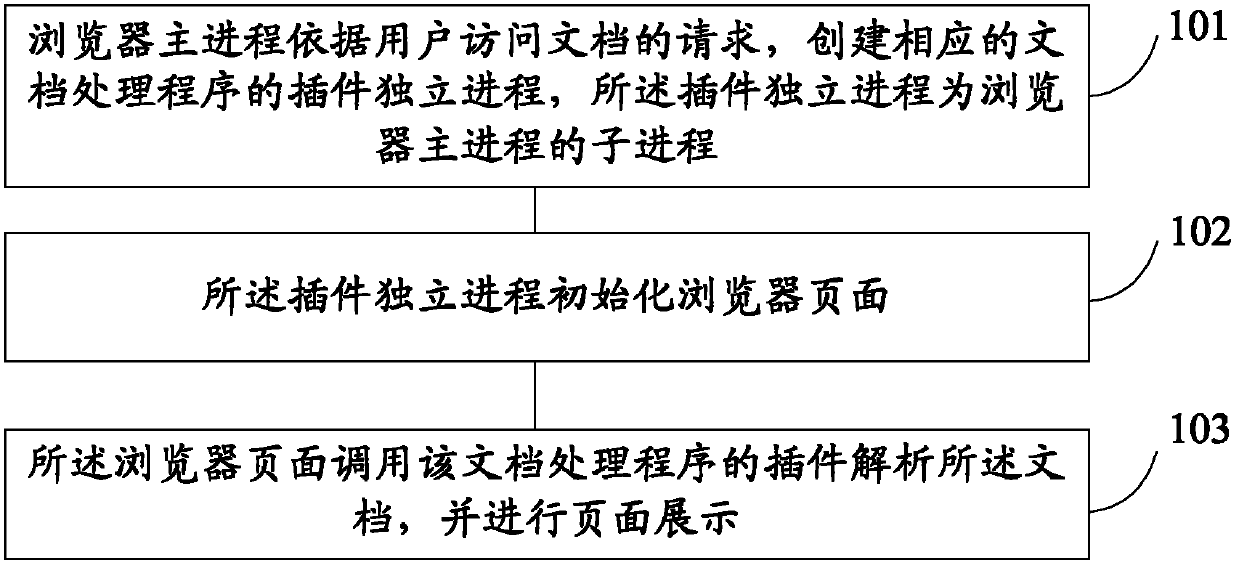

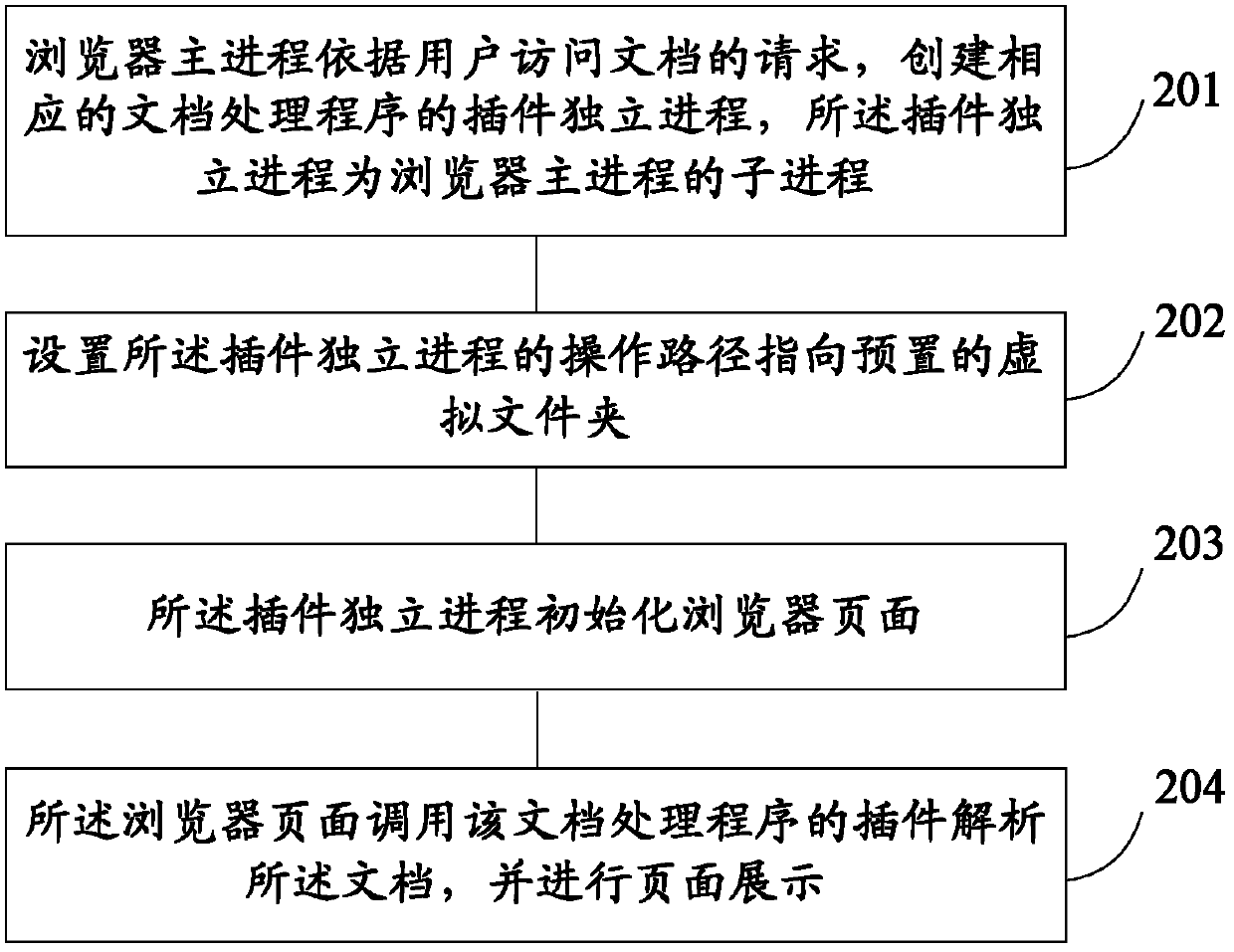

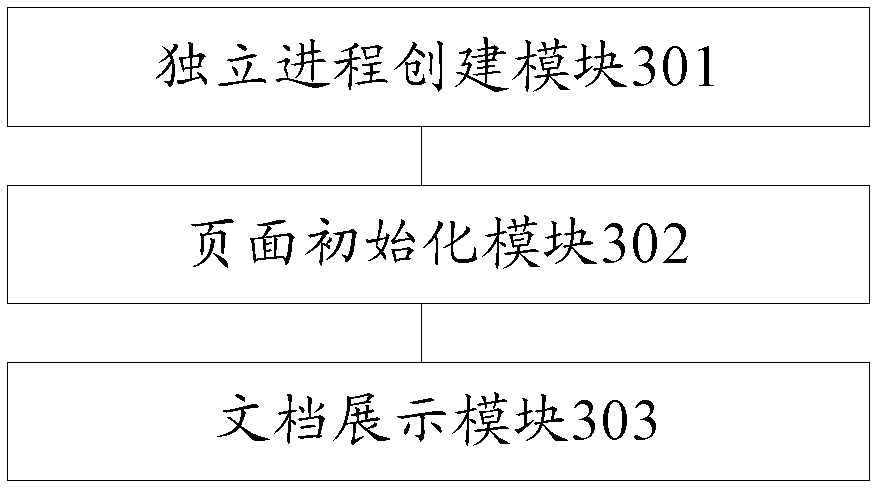

Method and device for displaying document in browser

ActiveCN102622439AProcess impactPlatform integrity maintainanceSpecial data processing applicationsDocumentationVirus

The invention provides a method and a device for displaying a document in a browser. The method comprises the following steps that: a browser host process establishes a plug-in separate process of a corresponding document processing procedure according to a request for accessing the document of a user, wherein the plug-in separate process is a subprocess of the browser host process; the plug-in separate process initiates a browser page; and the browser page calls a plug-in of the document processing procedure to analyze the document and display the page. By the method and the device, the influence of the vulnerability of the document processing procedure on the application of the browser can be avoided, and a user computer is further prevented from being attacked by virus.

Owner:BEIJING QIHOO TECH CO LTD

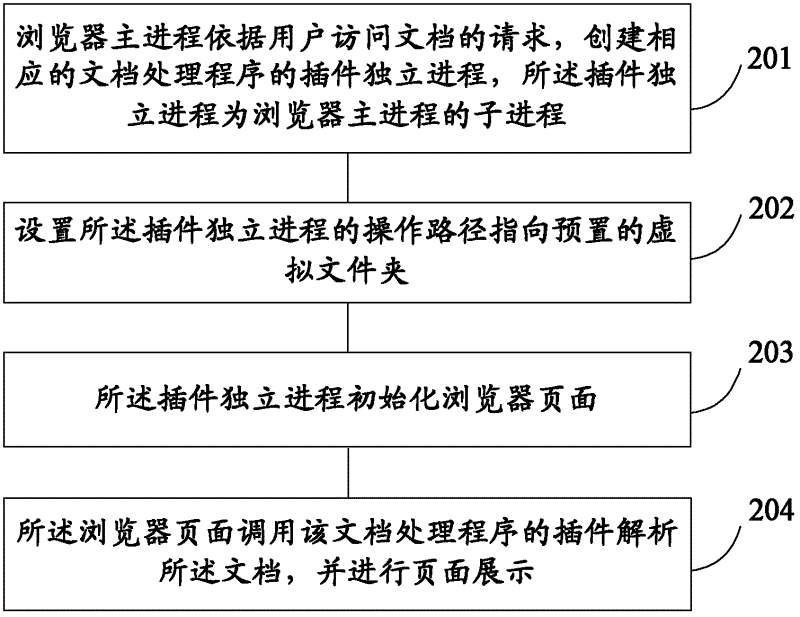

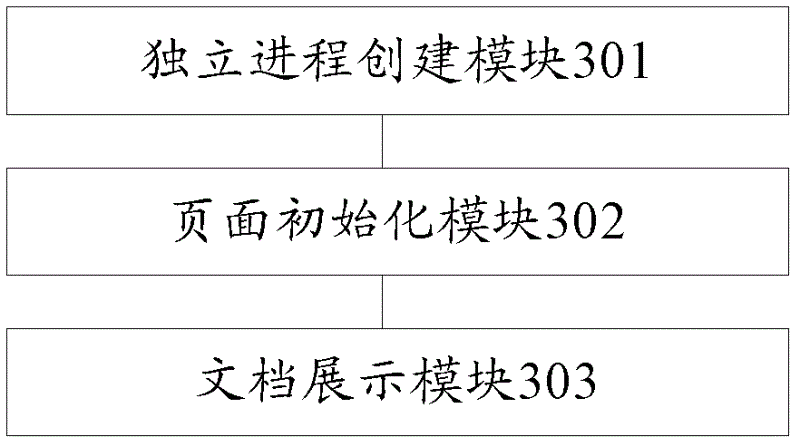

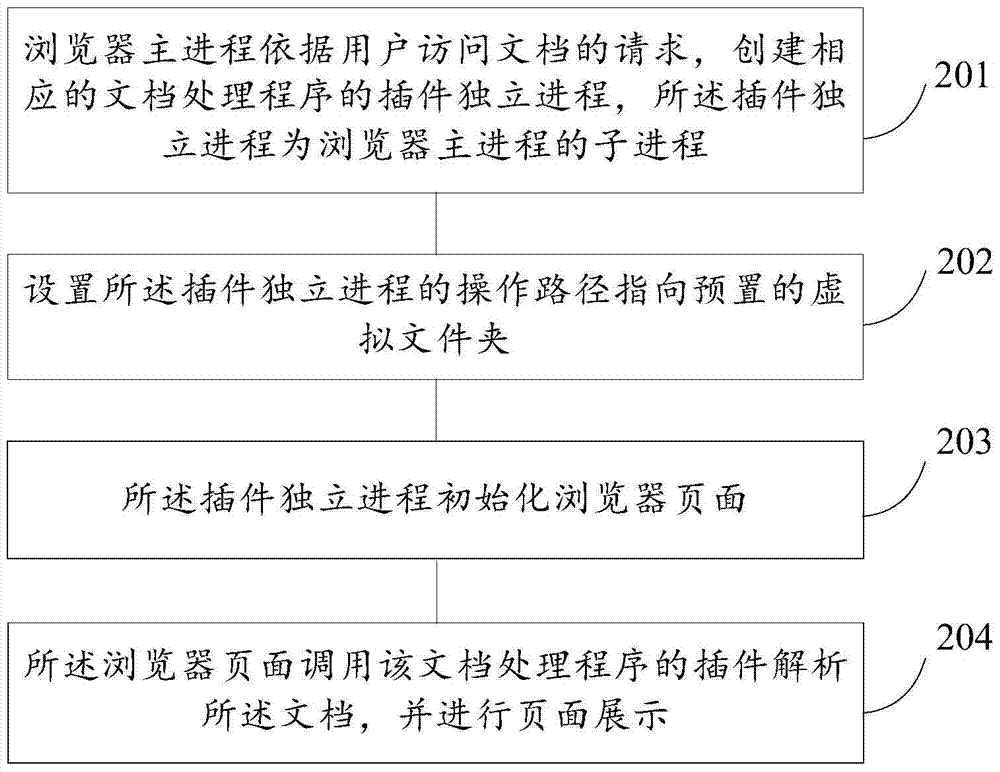

Method and device for displaying documents based on browser

InactiveCN103955468AProcess impactPlatform integrity maintainanceSpecial data processing applicationsWorld Wide WebVulnerability

The invention provides a method and a device for displaying documents in a browser. The method comprises the following steps of enabling a browser main process to create a plug-in independent process of a corresponding document processing program according to the request of a user accessing a document, wherein the plug-in independent process is the sub-progress of the browser main process; enabling the plug-in independent process to initialize a browser page; enabling the browser page to call the plug-in of the document processing program to analyze the document, and carrying out page displaying. The method and the device have the advantage that the influence of the loophole and Trojan of the document processing program on the use of the browser is avoided, and the computer viruses of the user are avoided.

Owner:BEIJING QIHOO TECH CO LTD +1

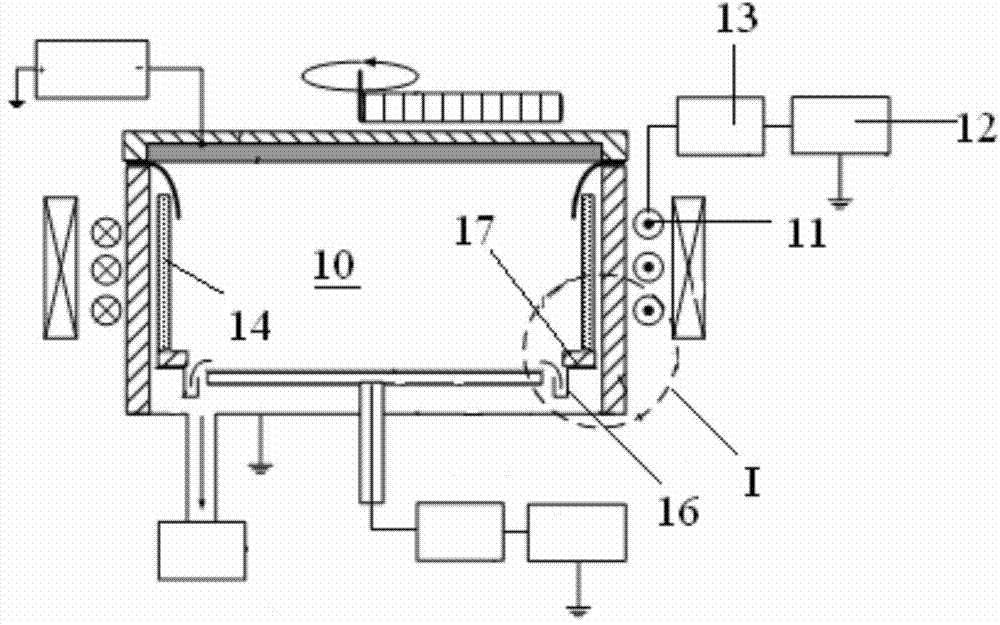

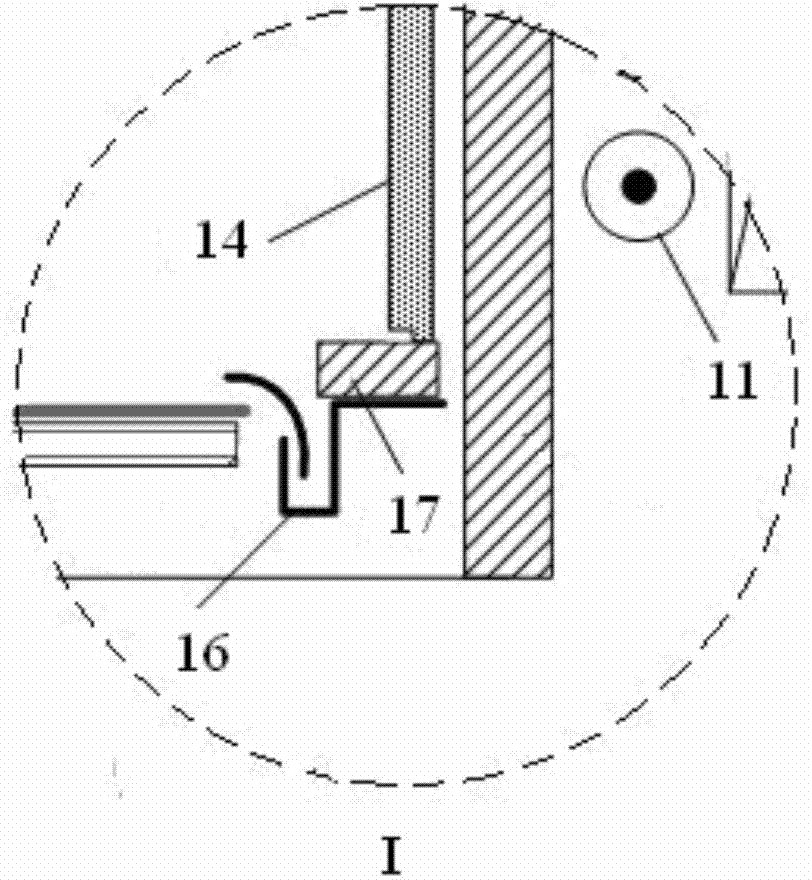

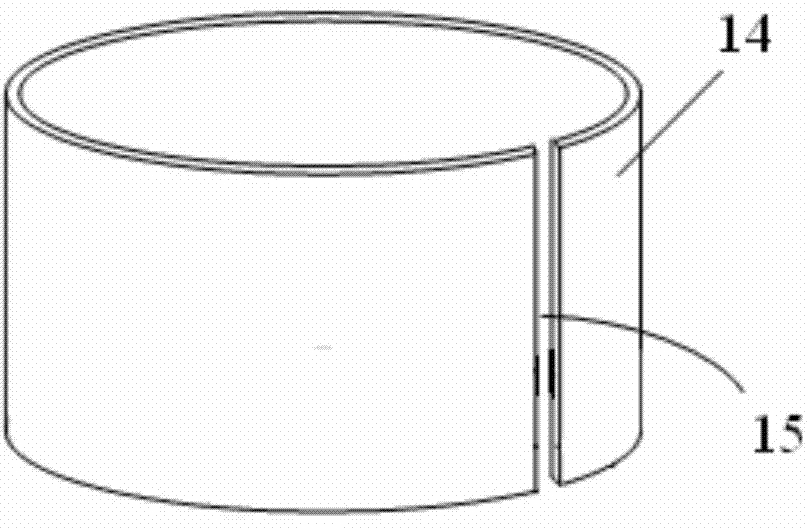

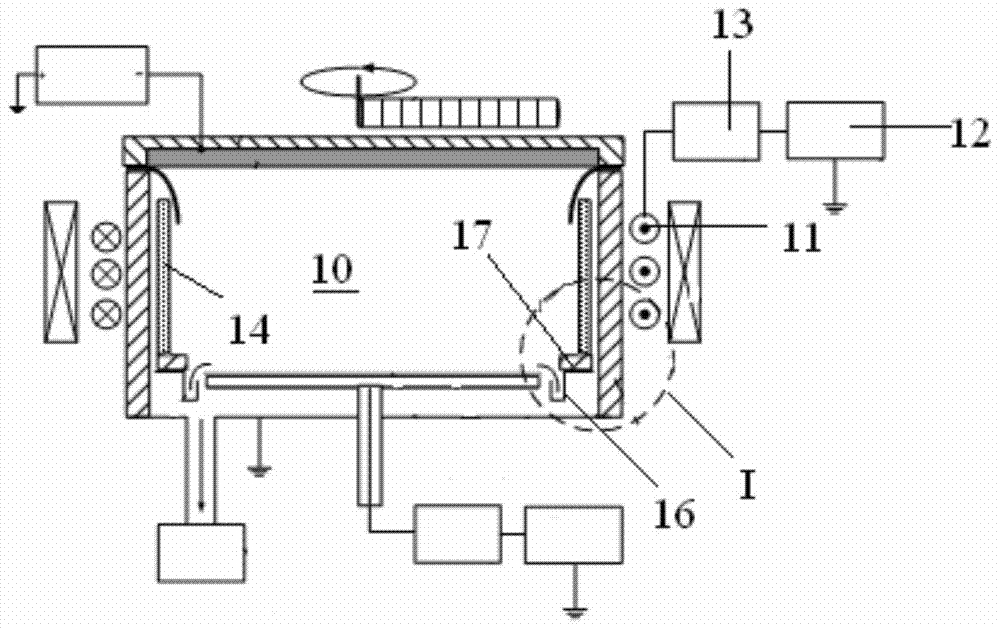

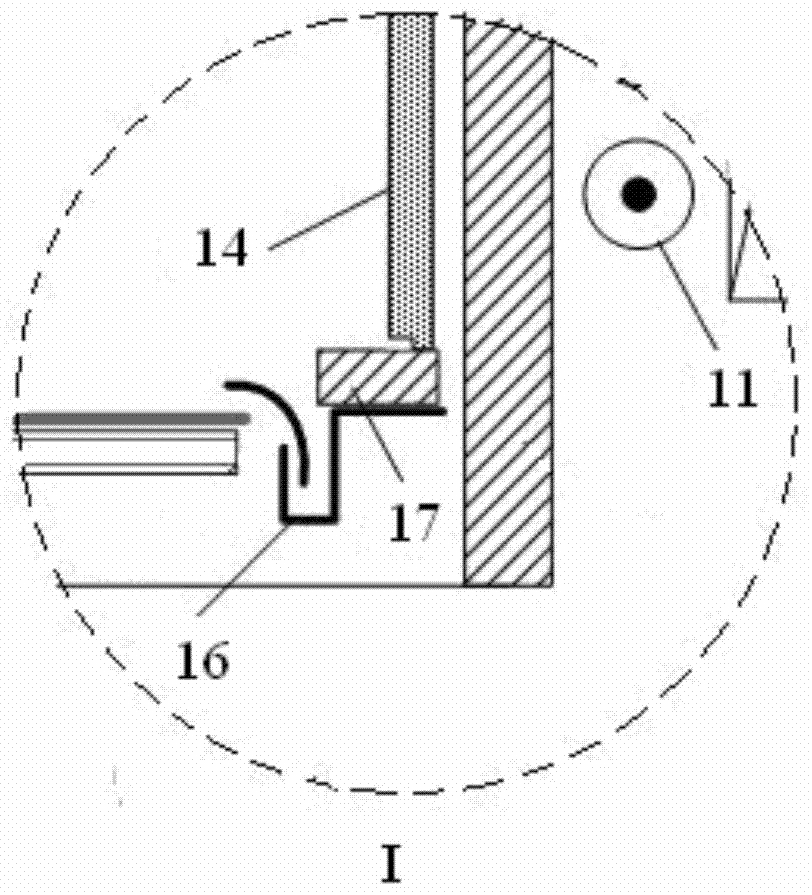

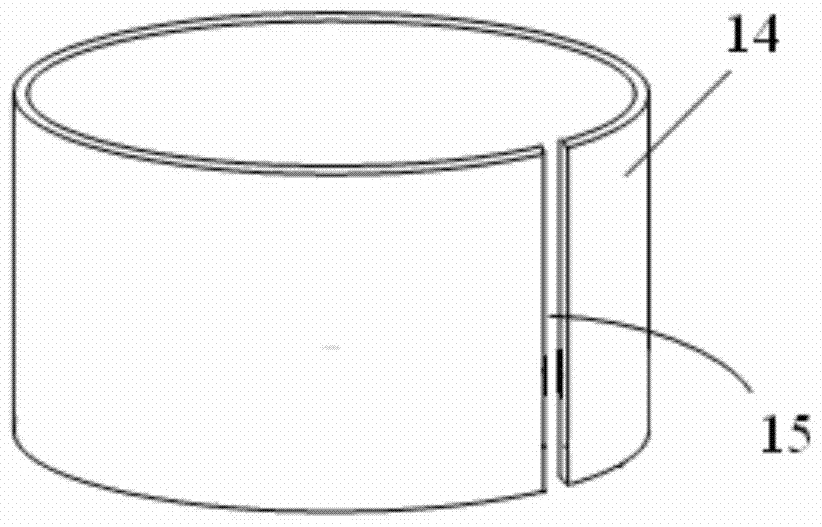

Reaction chamber and plasma processing equipment

ActiveCN104746043AAvoid formingProcess impactChemical vapor deposition coatingPlasma techniqueProcess qualityMetallic materials

The invention provides a reaction chamber and plasma processing equipment. The reaction chamber comprises a Faraday shield sleeving the inner side of the side wall of the reaction chamber, an insulating ring and a shielding ring made from a non-magnetic conductive metal material, wherein the Faraday shield is overlapped on the insulating ring, at least one seam is arranged along the circumferential direction of the Faraday shield at intervals, the seam is arranged along the vertical direction of the Faraday shield, and the shielding ring is surrounded on the inner side at the connecting site of the Faraday shield and the insulating ring and is not in contact with the Faraday shield; the shielding ring is used for shielding metal ions in the reaction chamber to deposit the seam at the connecting site of the seam and the insulating ring. The reaction chamber provided by the invention can be used for improving the process stability in the reaction chamber so as to improve the process quality.

Owner:BEIJING NAURA MICROELECTRONICS EQUIP CO LTD

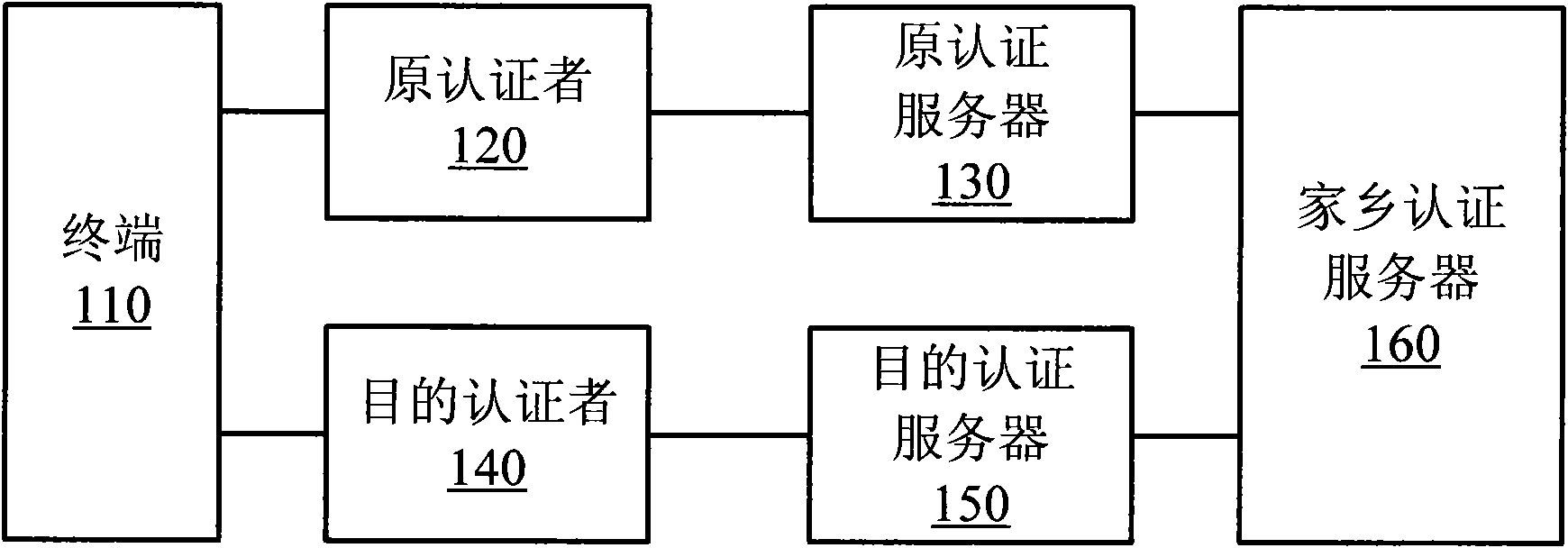

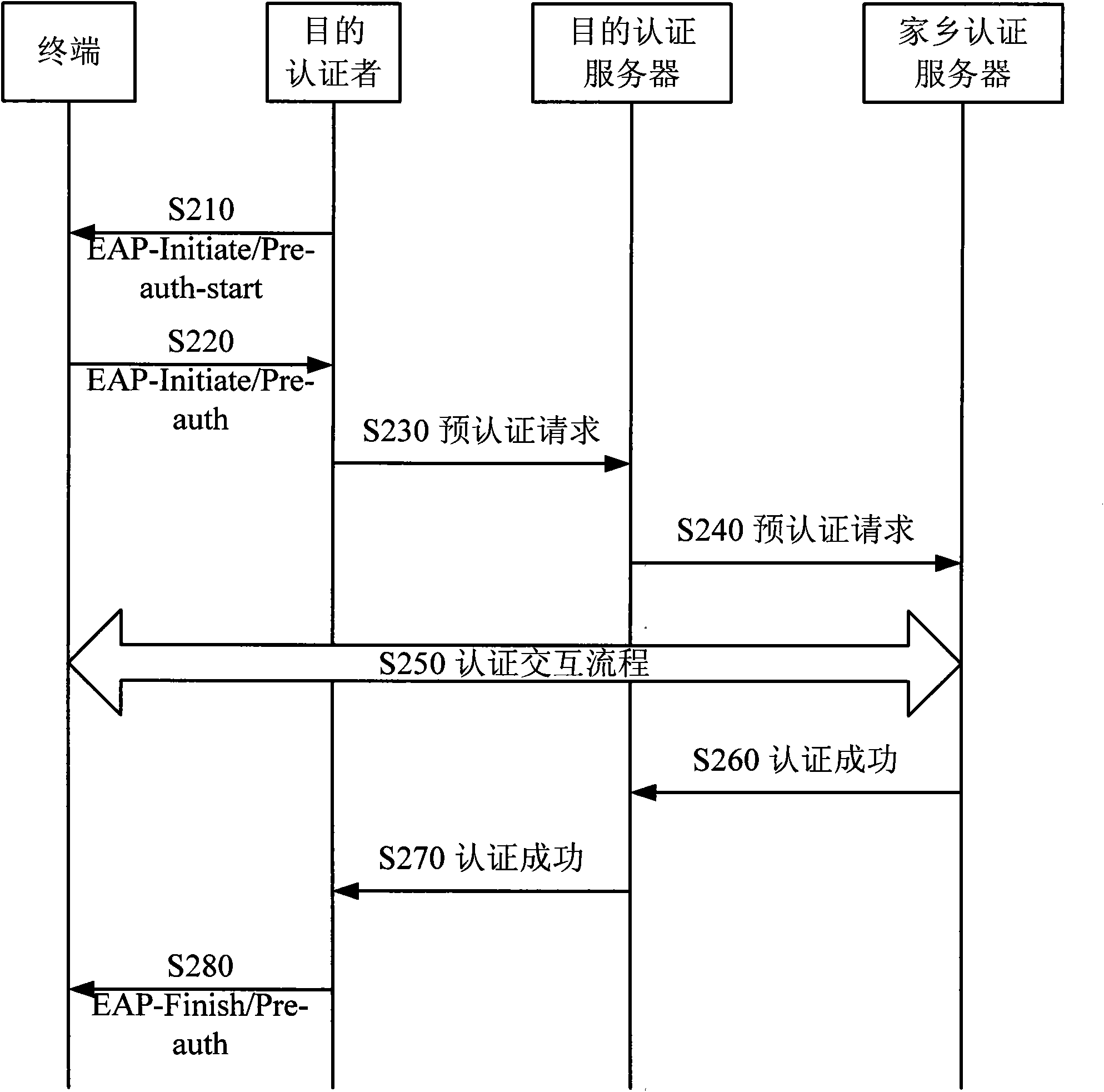

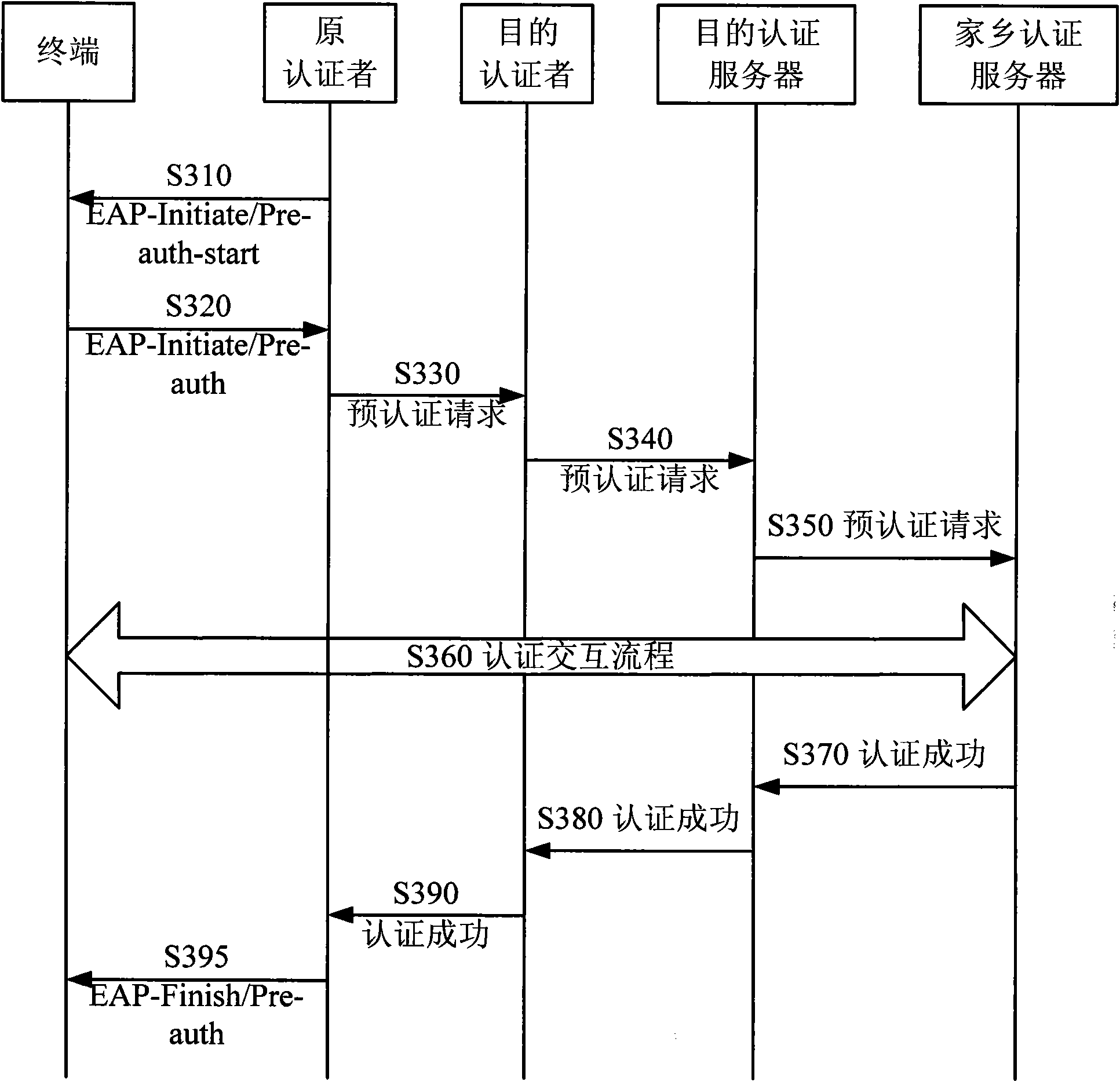

System and method for preauthenticating terminal switched among different management domains

InactiveCN102065425ARealize switchingReduce switching delaySecurity arrangementAuthentication serverSwitching time

The invention discloses a system and a method for preauthenticating a terminal switched among different management domains, which can reduce the switching time delay of the terminal switched among the different management domains during switching. The method comprises the following steps that: the terminal transmits a preauthentication request to a hometown authentication server after receiving a preauthentication initiating message sent by the original management domain or a destination management domain; the hometown authentication server and the terminal perform preauthentication interaction; and the hometown authentication server sends a preauthentication success message to the terminal and the destination management domain after the preauthentication succeeds. By the system and the method, after a user who is successfully preauthenticated switches the terminal, the authentication process of switching to the destination management domain is reduced, the time delay is reduced, and the service continuity is improved.

Owner:ZTE CORP

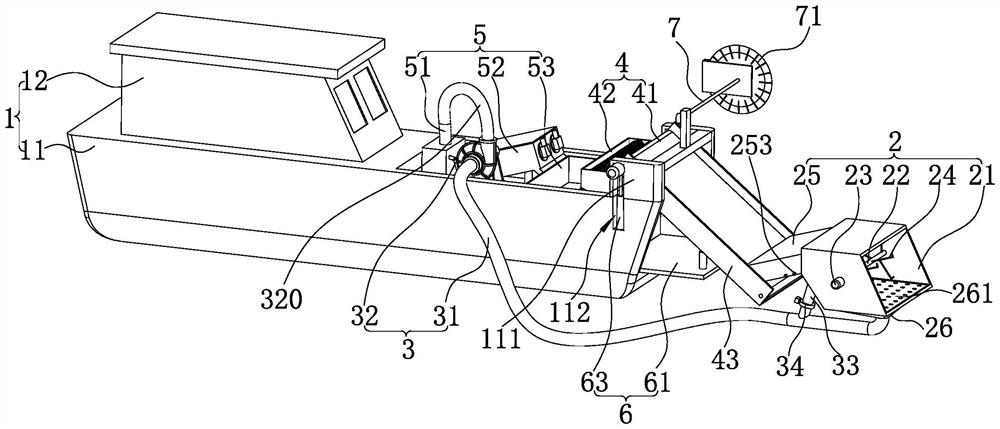

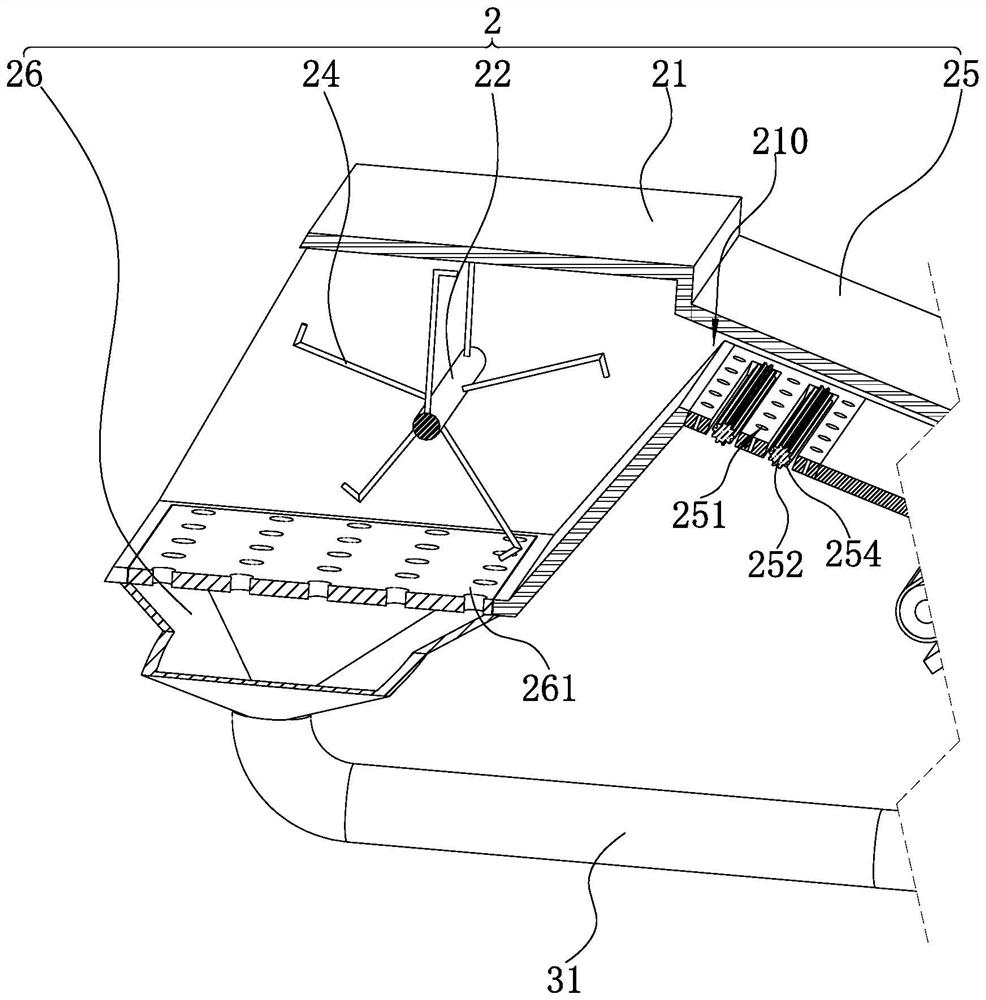

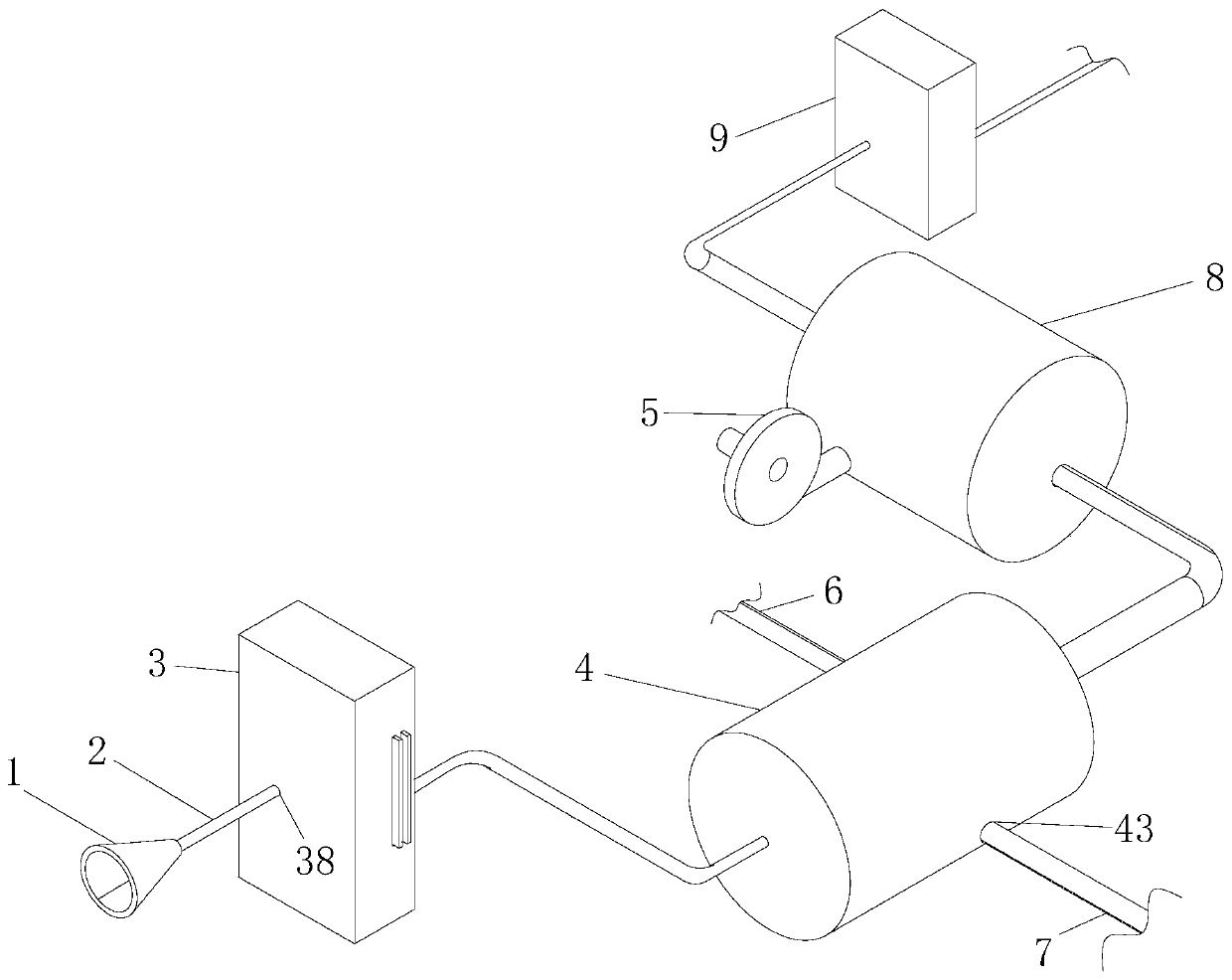

River channel dredging device and dredging method

ActiveCN114059608AImprove dredging effectProcess impactWater resource protectionMechanical machines/dredgersRiver routingSludge

The invention discloses a river channel dredging device and a dredging method, and belongs to the technical field of river channel dredging. The river channel dredging device comprises a dredging ship body, a salvage assembly arranged at the bottom of the dredging ship body and used for separating sundries and sludge in a river channel sludge layer, a sludge suction assembly arranged on the dredging ship body, communicated with the salvage assembly and used for sucking away the sludge separated from the salvage assembly, a sundry treatment assembly which is arranged on the dredging ship body, communicates with the salvage assembly and is used for treating sundries separated from the river channel sludge layer, and a sludge treatment assembly which is arranged on the dredging ship body, communicates with the sludge suction assembly and is used for treating sludge discharged from the sludge suction assembly. The river channel dredging effect can be better.

Owner:王立玲

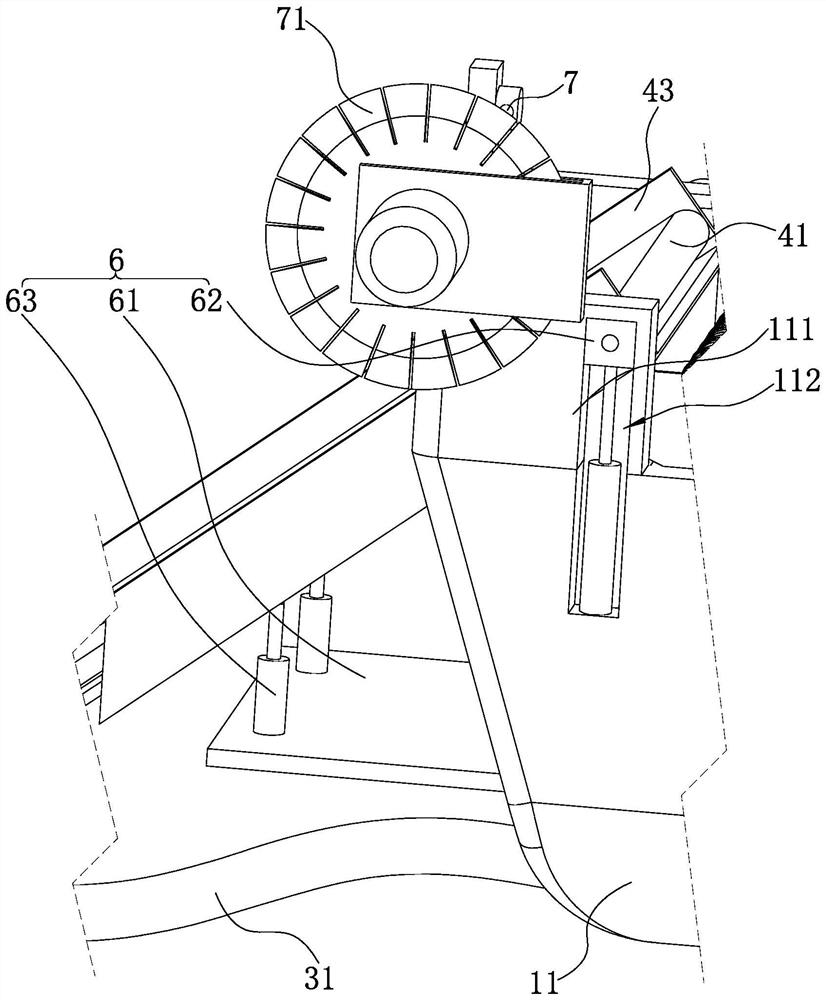

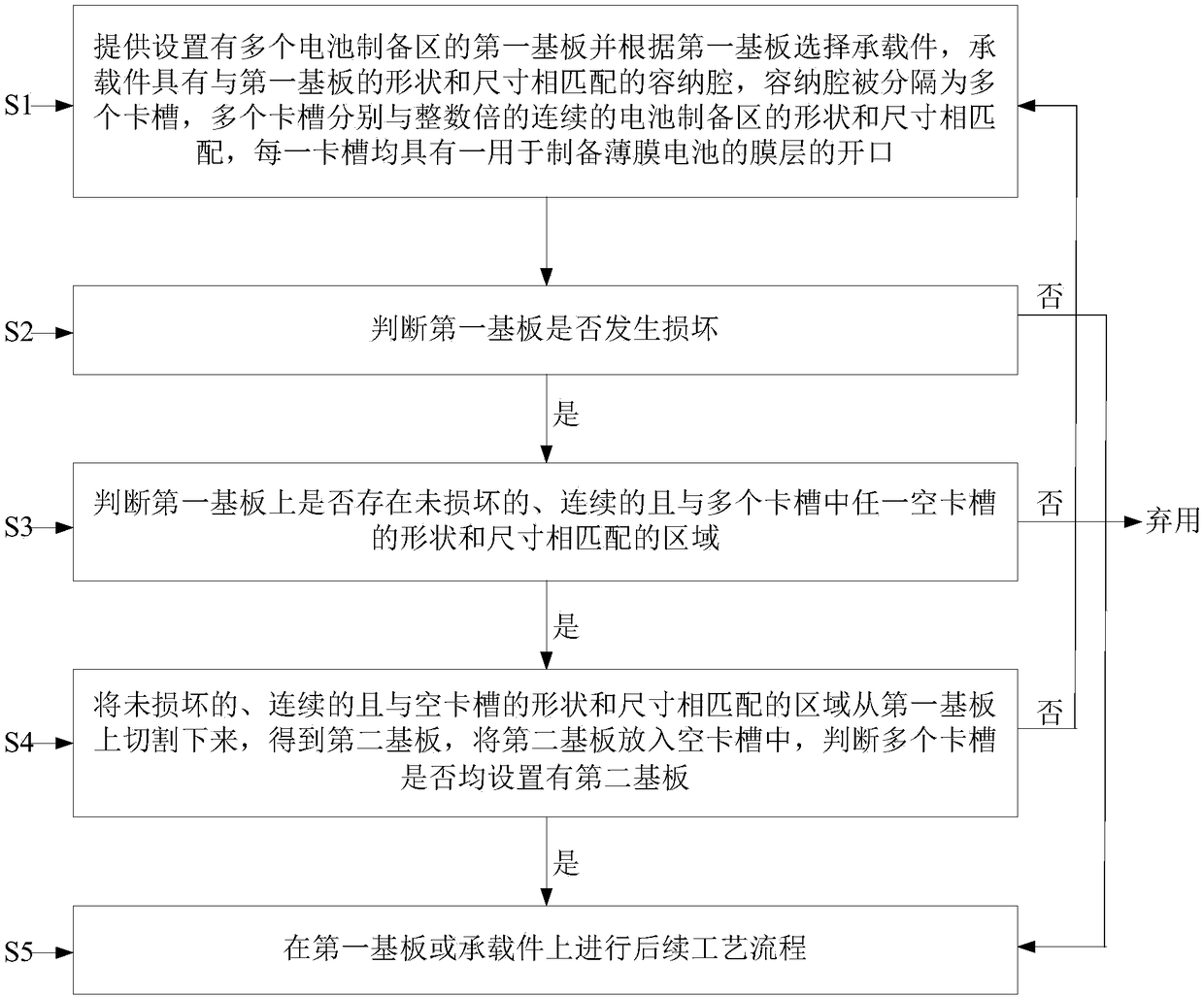

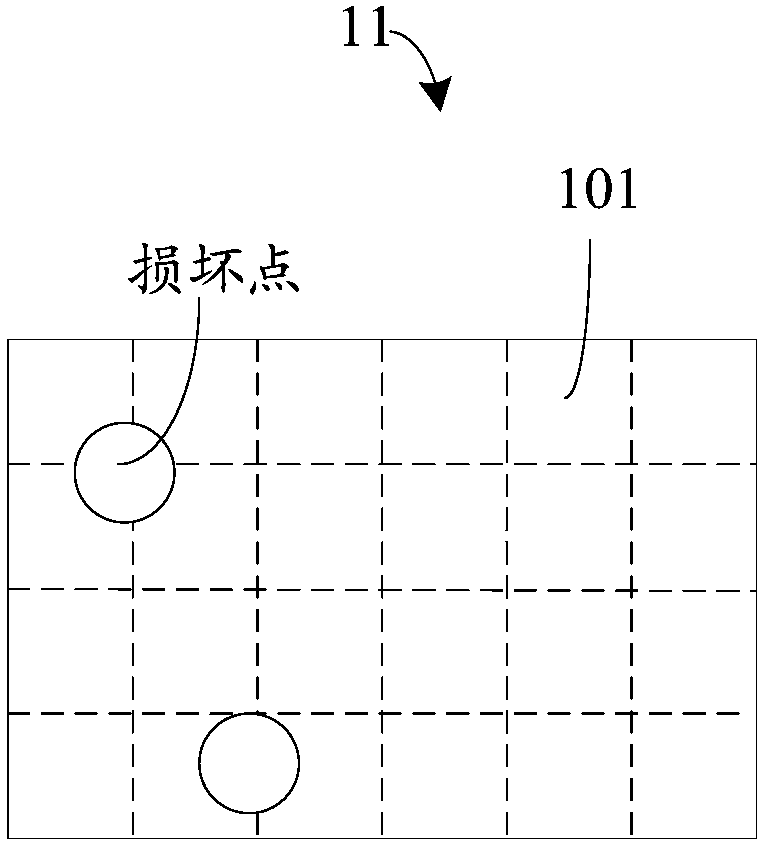

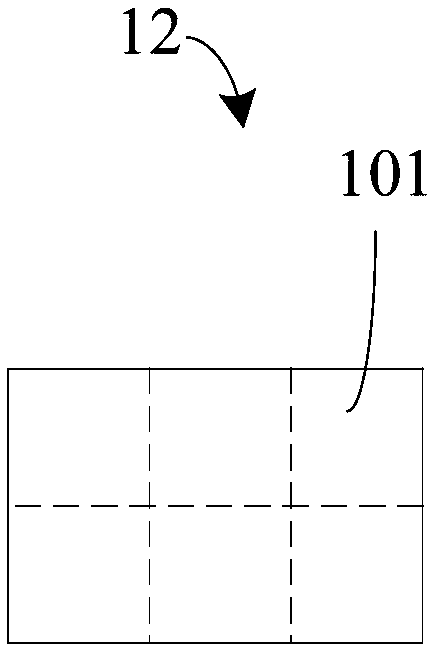

Manufacturing method of film cell

ActiveCN108447800AImprove production yieldAvoid wastingFinal product manufactureSemiconductor/solid-state device manufacturingUtilization rateManufacturing engineering

The invention provides a manufacturing method of a film cell. When a first substrate is damaged, damage-less areas are cut off and are disposed in a slot of a carrier member, the multiple damage-lessareas of the first substrates are spliced through the carrier member to form a spliced substrate corresponding to the first substrate, when the process enters the subsequent process, subsequent manufacturing is carried out through employing the process program and parameters same as the first substrate, not only can influence on the subsequent process be avoided, but also material waste is avoided, the material utilization rate is improved, the production yield of film cells is improved, and manufacturing cost is reduced. The invention further provides a manufacturing method of a non-standardfilm cell.

Owner:上海祖强能源有限公司

Fibre flame-retardant processing method for flame-retardant medium-density fiberboard

InactiveCN101412240AAvoid thermal decompositionReduce dosageFlat articlesDomestic articlesDecompositionMedium density fiberboard

The invention discloses a method for flame retardant treatment of a fiber to produce a flame retardant medium density fiberboard. The method is characterized in that a mixed flame retardant is adopted to perform flame retardant treatment on the fiber, and each component in the mixed flame retardant is applied by two times according to the decomposition temperature which is higher or lower than the fiber drying temperature. The method comprises the following steps: firstly, applying the component the decomposition temperature of which is higher than the fiber drying temperature to the fiber from a discharging opening of a prefiner; and secondly, preparing the component the decomposition temperature of which is lower than the fiber drying temperature into powder, and applying the component to fiber flow from a discharging opening of a storage bin after the fiber is dried. The method for the flame retardant treatment of the fiber not only cannot increase the burden of a fiber drier, but also can prevent certain flame retardant with lower decomposition temperature from being decomposed in the process of drying the fiber, thus the usage of the flame retardant is reduced, the flame retardant effect is improved, and the modern continuous production process of the medium density fiberboard is not changed.

Owner:NANJING FORESTRY UNIV

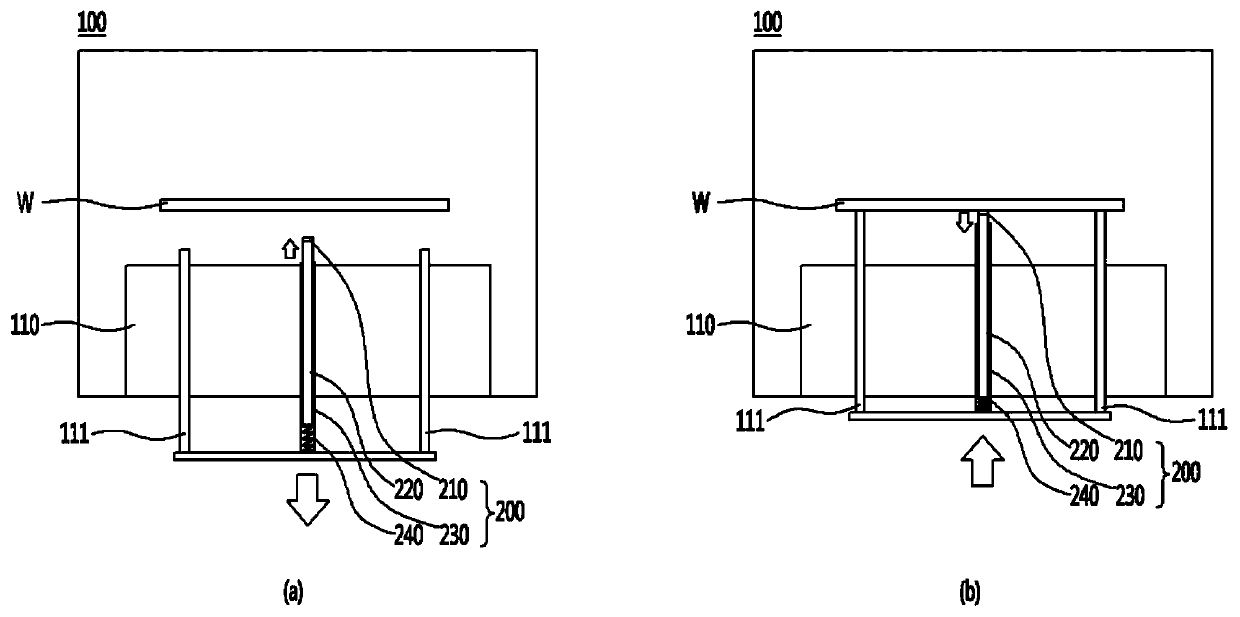

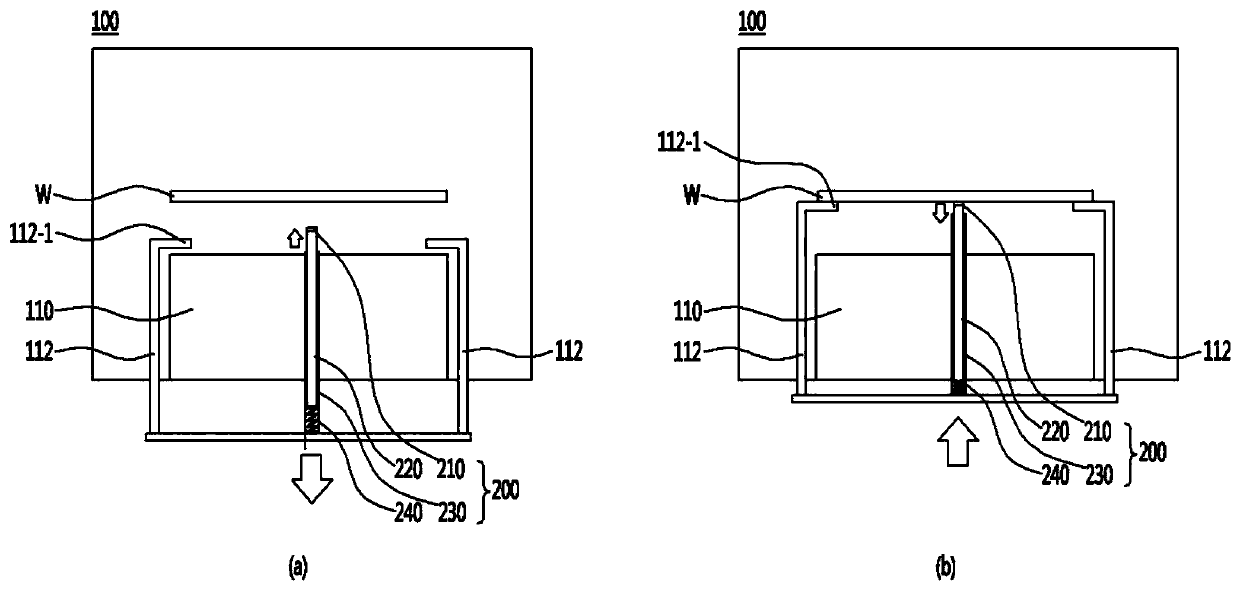

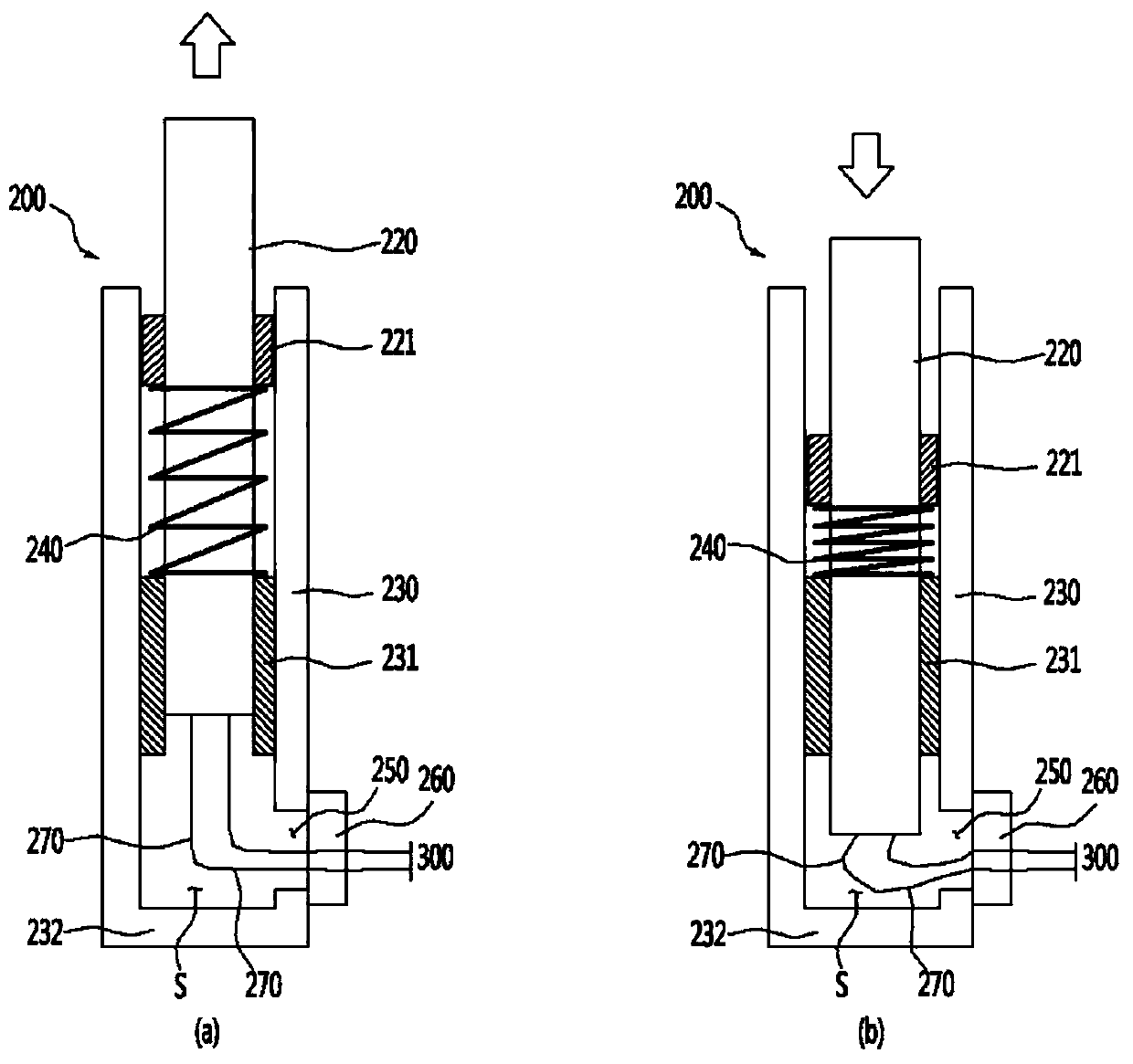

Apparatus for measuring temperature of substrate and the method thereof

ActiveCN111089659AReal-time measurement of temperatureReduce the incidence of adverse eventsThermometer detailsSemiconductor/solid-state device testing/measurementEngineeringMaterials science

The present invention relates to a substrate temperature measuring device and a substrate temperature measuring method and, more specifically, to a substrate temperature measuring device and a substrate temperature measuring method, which can measure the temperature of a substrate in a substrate processing process in real time. To this end, according to the present invention, the substrate temperature measuring device includes a probe which vertically penetrates a substrate support for supporting the substrate to perform the substrate processing process, and which has an upper end protruding from an upper surface of the substrate support. The upper end of the probe is formed to measure the temperature by being in contact with a lower side of the substrate.

Owner:SUBARU TECNICA INTERNATIONAL

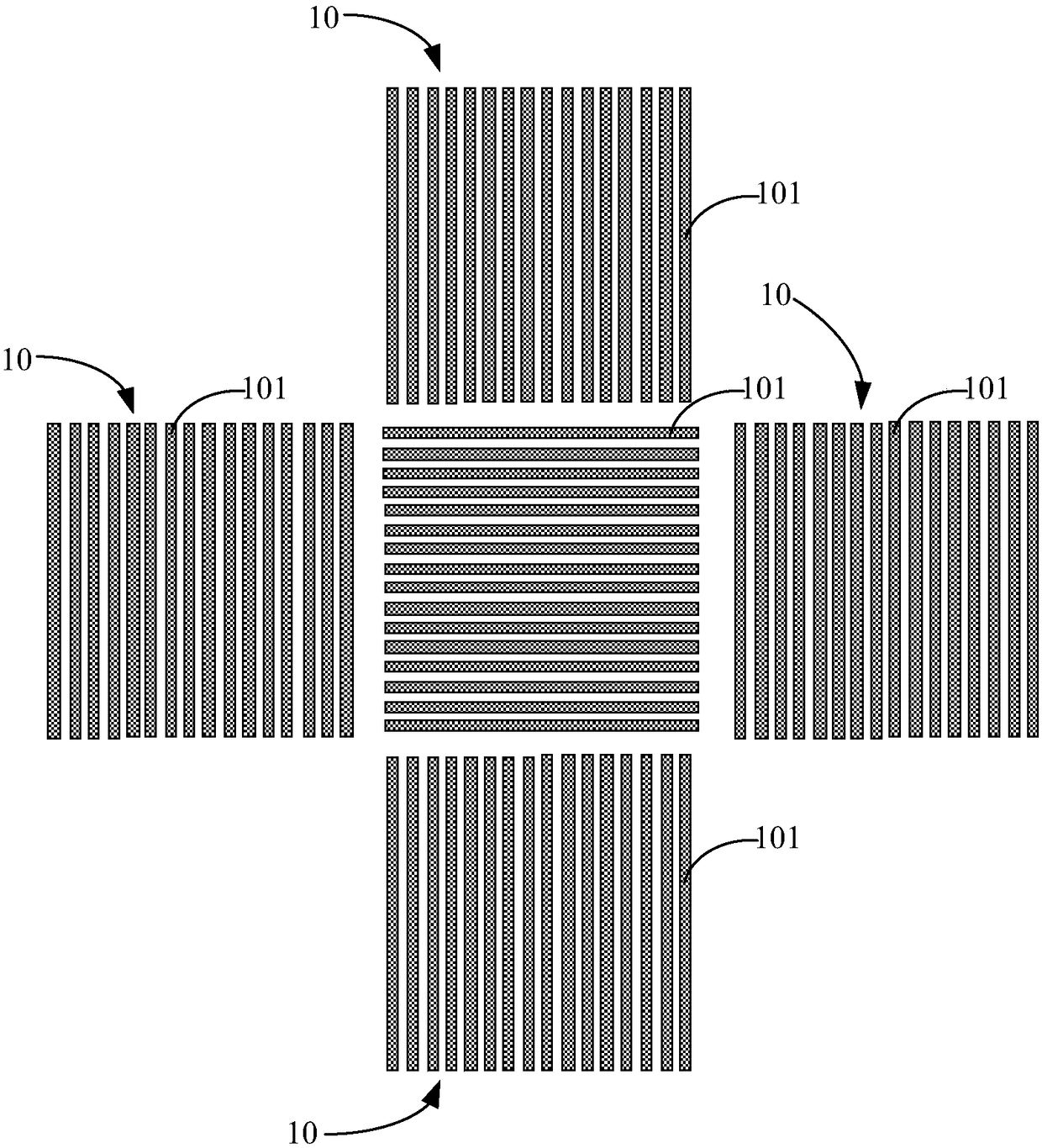

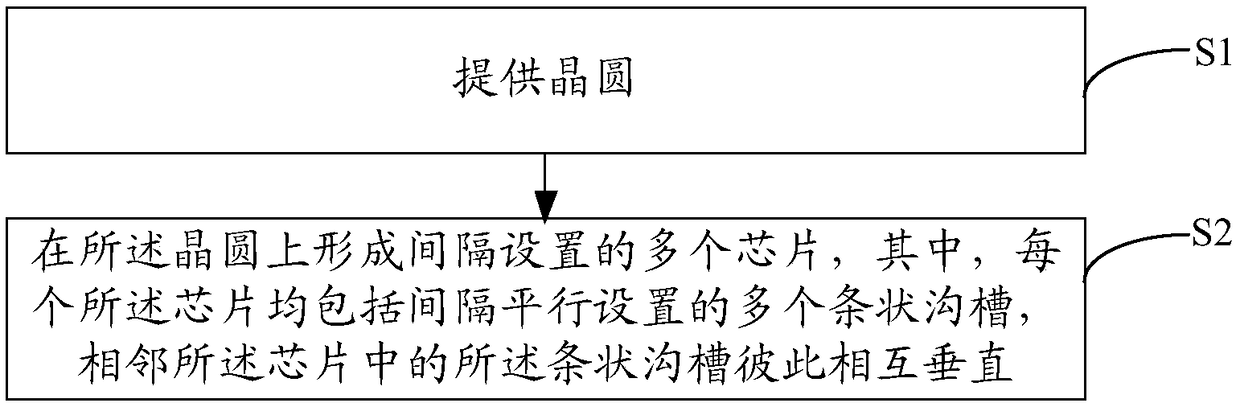

Semiconductor device and manufacture method thereof

ActiveCN108231757AImprove warpageDeposition process influenceTransistorSolid-state devicesPower semiconductor deviceEngineering

The invention provides a semiconductor device and manufacture method thereof. The semiconductor device includes a wafer. A plurality of chips are arranged on the wafer in a spaced manner. Each chip includes a plurality of strip-shaped grooves arranged in parallel and in a spaced manner. The strip-shaped grooves in the adjacent chips are perpendicular to each other. According to the invention, thestrip-shaped grooves in the adjacent chips are perpendicular to each other, wafer warping caused by groove and grid filling compensates with each other, so that the warping of the whole wafer is relieved. At the same time, a regular deposition technique for the grid layer can be kept and no influence is caused on the technique. Easy implementation is achieved.

Owner:SEMICON MFG INT (SHANGHAI) CORP +1

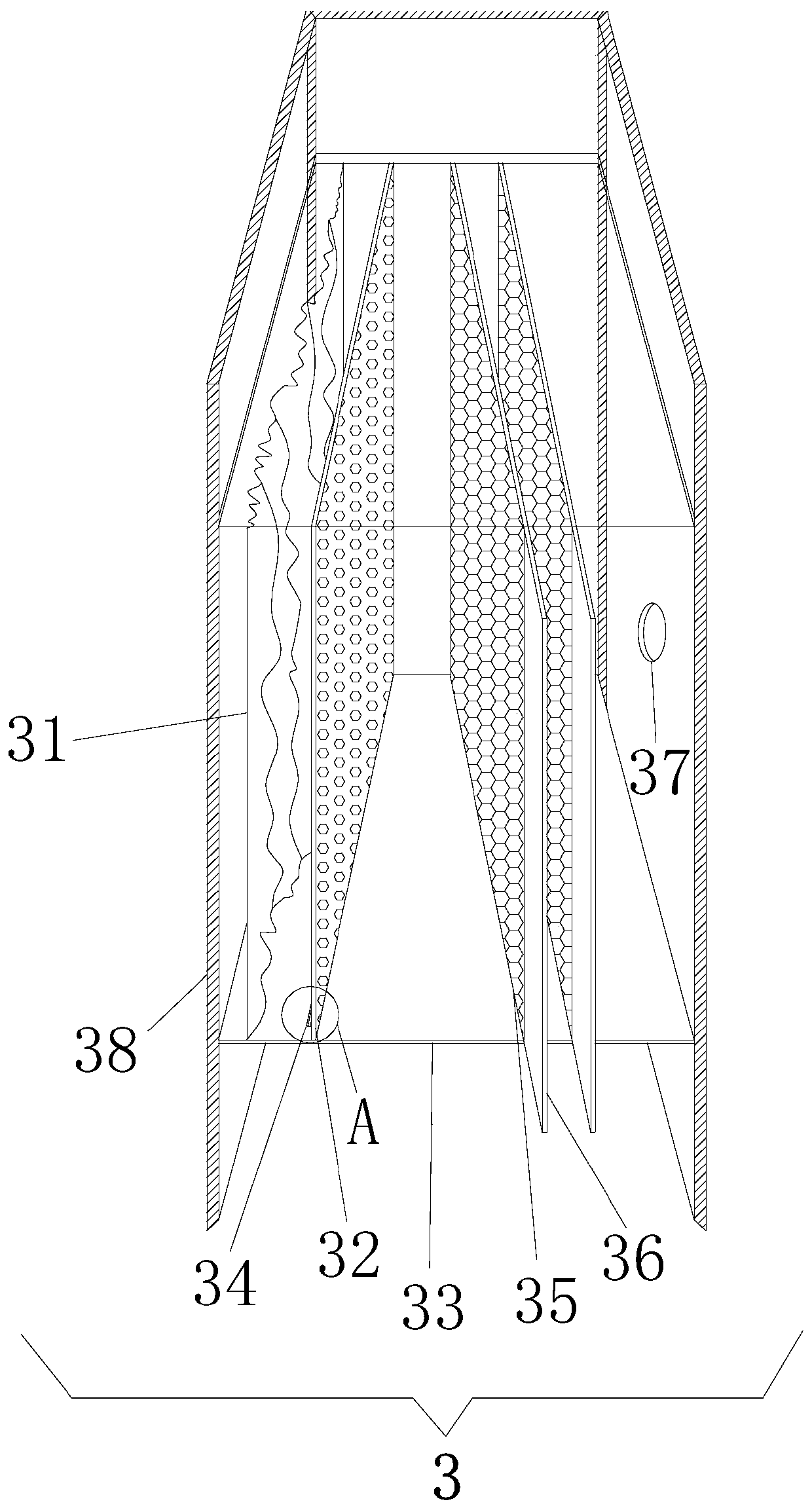

Energy-saving and environmentally friendly industrial waste gas treatment device

InactiveCN110252041AGuaranteed normal operationWill not affect operationGas treatmentDispersed particle filtrationActivated carbonParticulates

The invention provides an energy-saving and environmentally friendly industrial waste gas treatment device, and relates to the technical field of industrial waste gas treatment. The energy-saving and environmentally friendly industrial waste gas treatment device includes a waste gas collection device. The waste gas collection device is fixedly connected to a filter device through a pipeline. Fixed plates are fixedly mounted in the filter device. Wet filter paper, a gas permeable plate and activated carbon plates are fixedly connected between the two fixed plates. Leakage grooves are arranged between each wet filter paper and the corresponding gas permeable plate. The two activated carbon plates are fixedly mounted behind the corresponding gas permeable plate. An extension plate is fixedly mounted on the right side of the corresponding activated carbon plates. The filter device is fixedly connected to a purification device through a pipeline. A flow guiding pipe is fixedly mounted in the purification device. A catalytic combustion device is fixedly mounted behind he purification device. A drying device is fixedly connected behind the catalytic combustion device. The filter device makes solid waste such as particles in the waste gas be first intercepted by the wet filter paper, and the solid waste can be intercepted by the gas permeable plates if the solid waste passes through the wet filter paper and falls into the leakage grooves, which does not affect the operation of the whole device.

Owner:莫庆锋

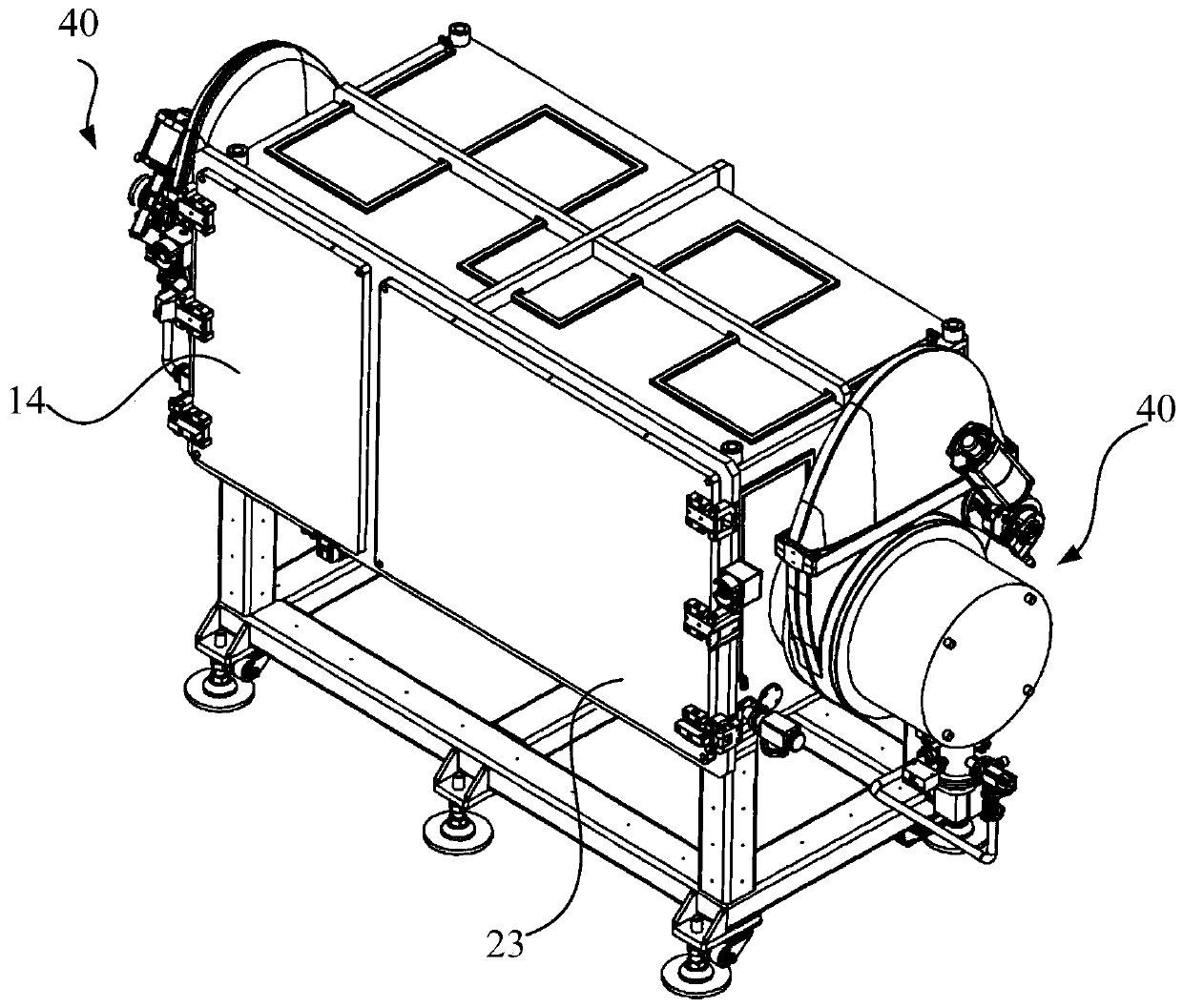

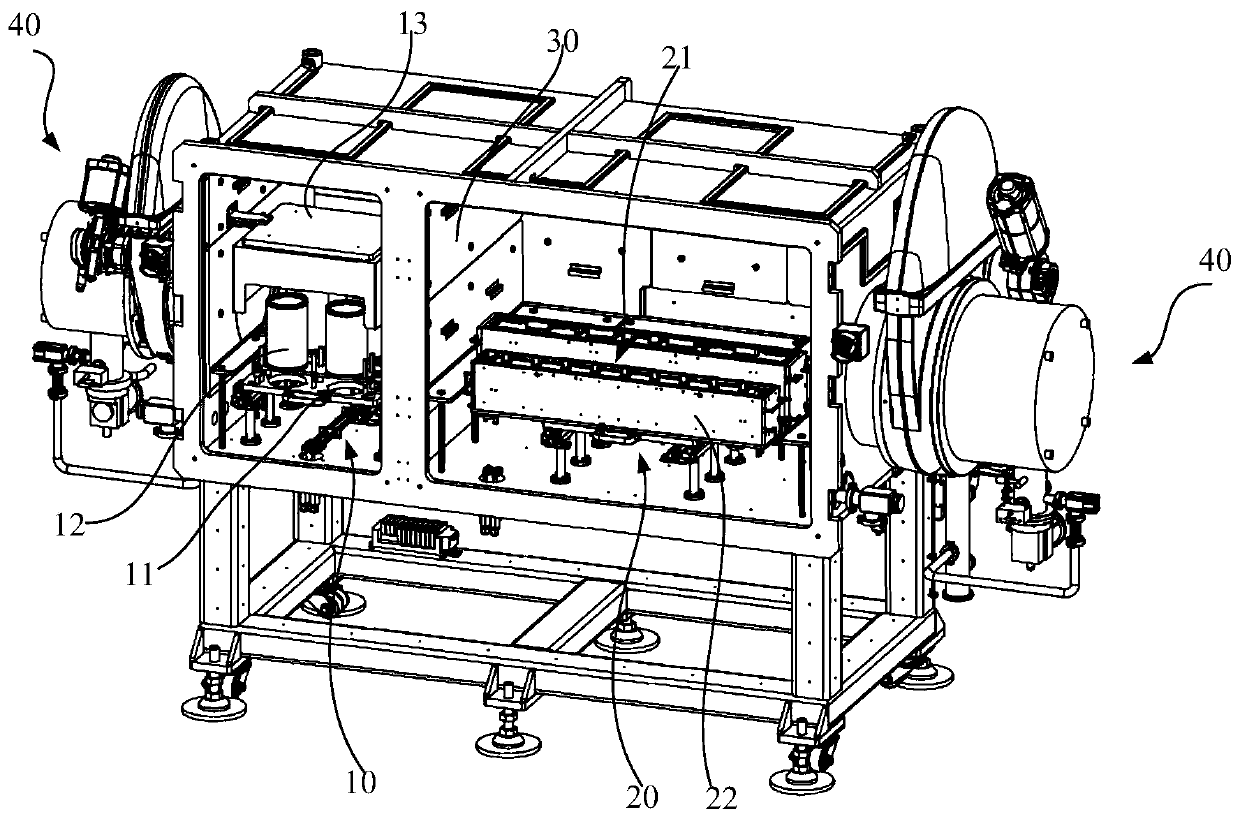

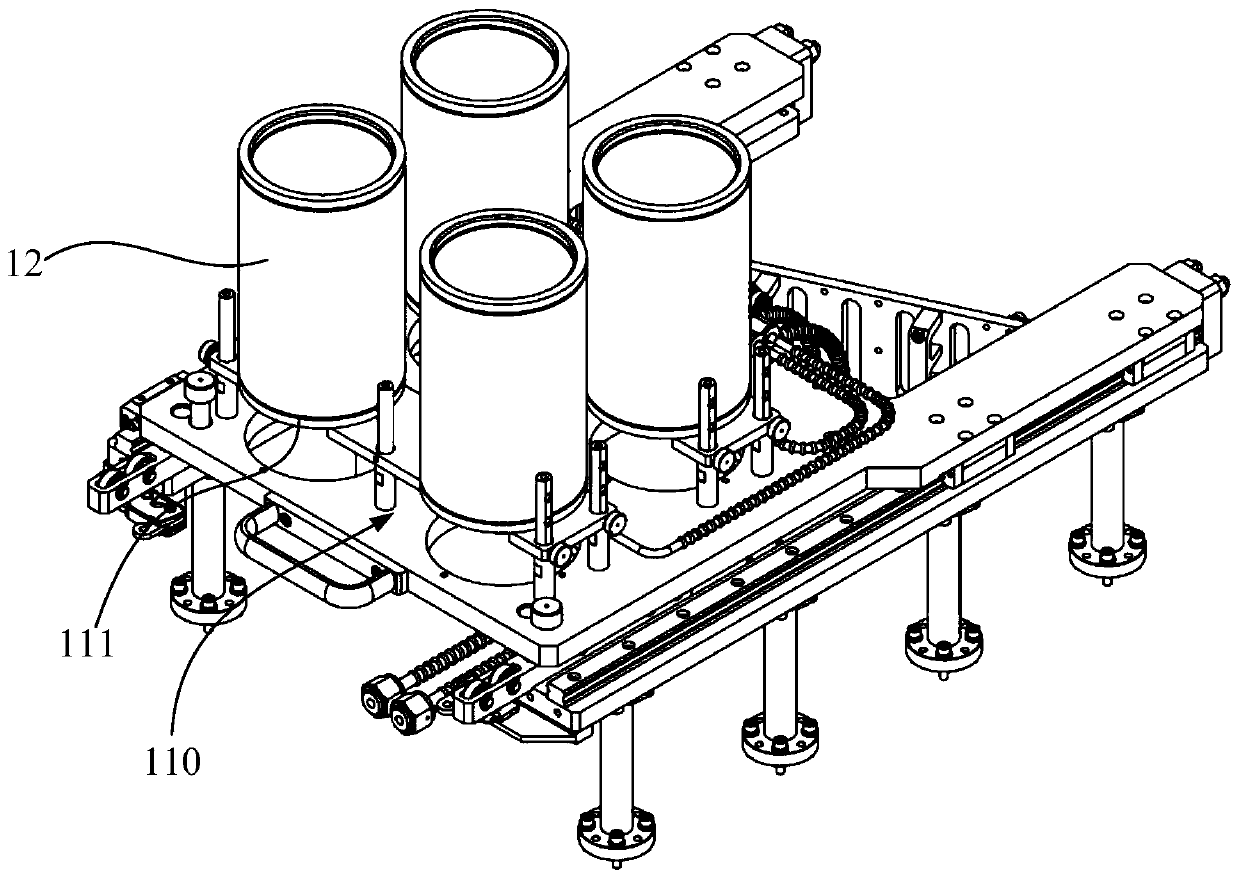

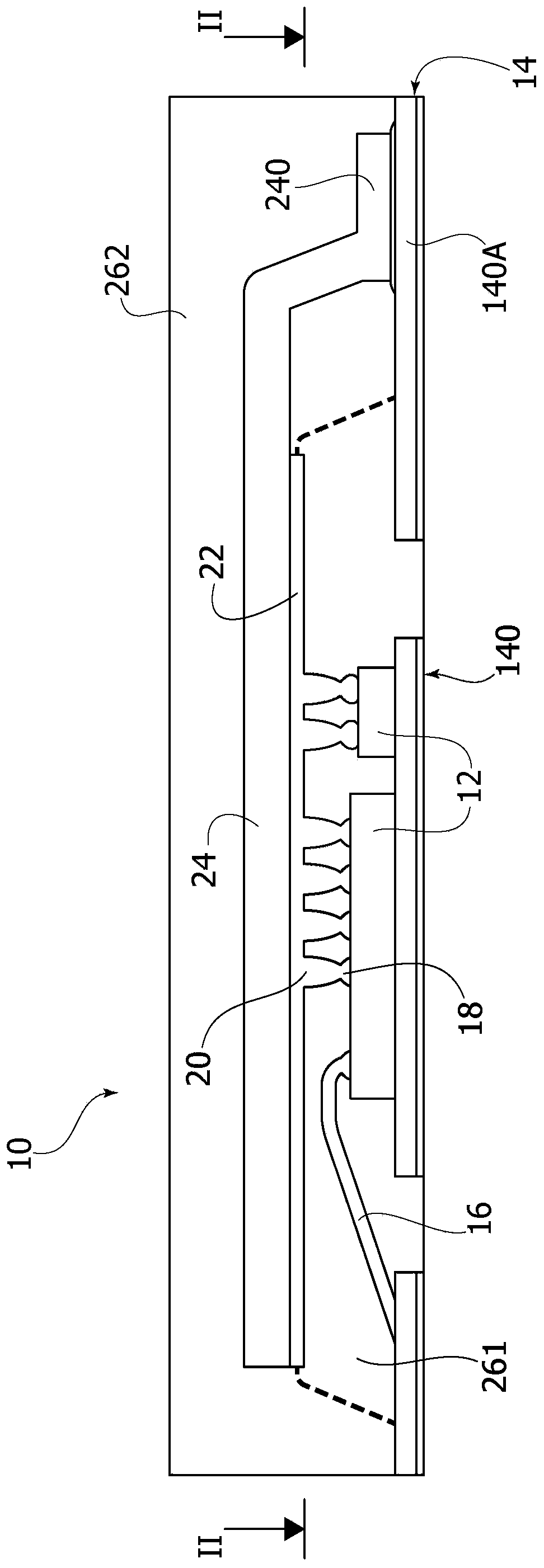

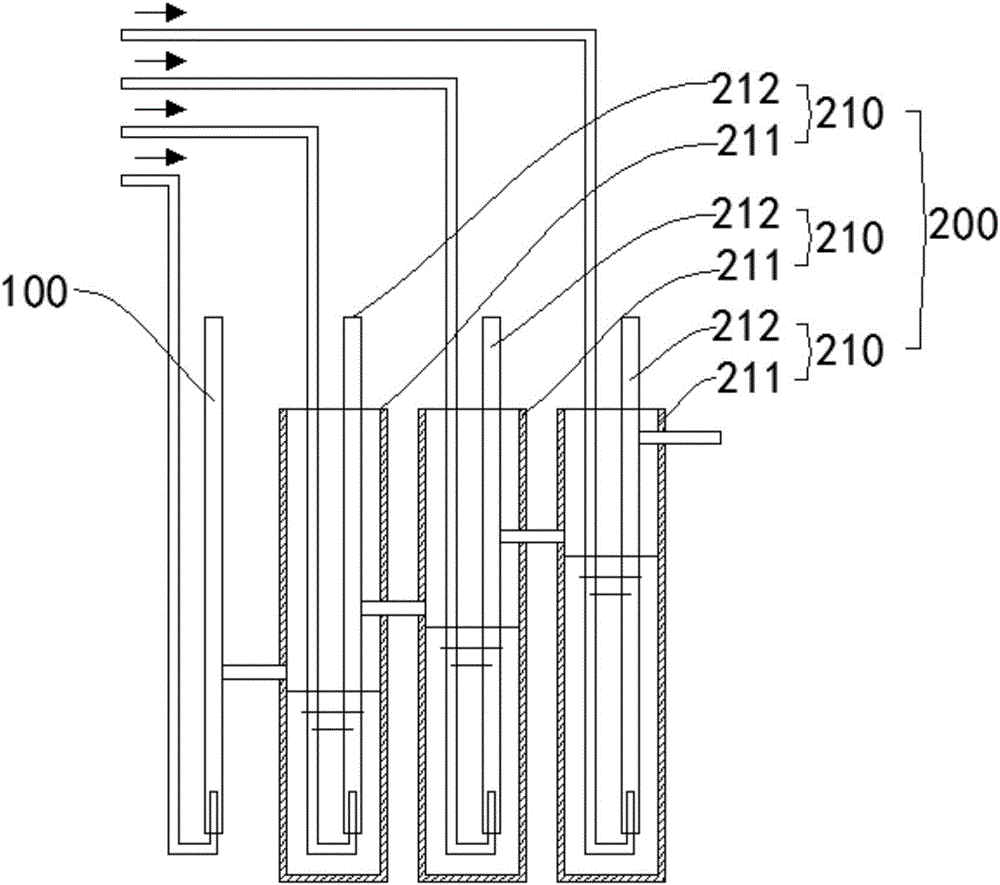

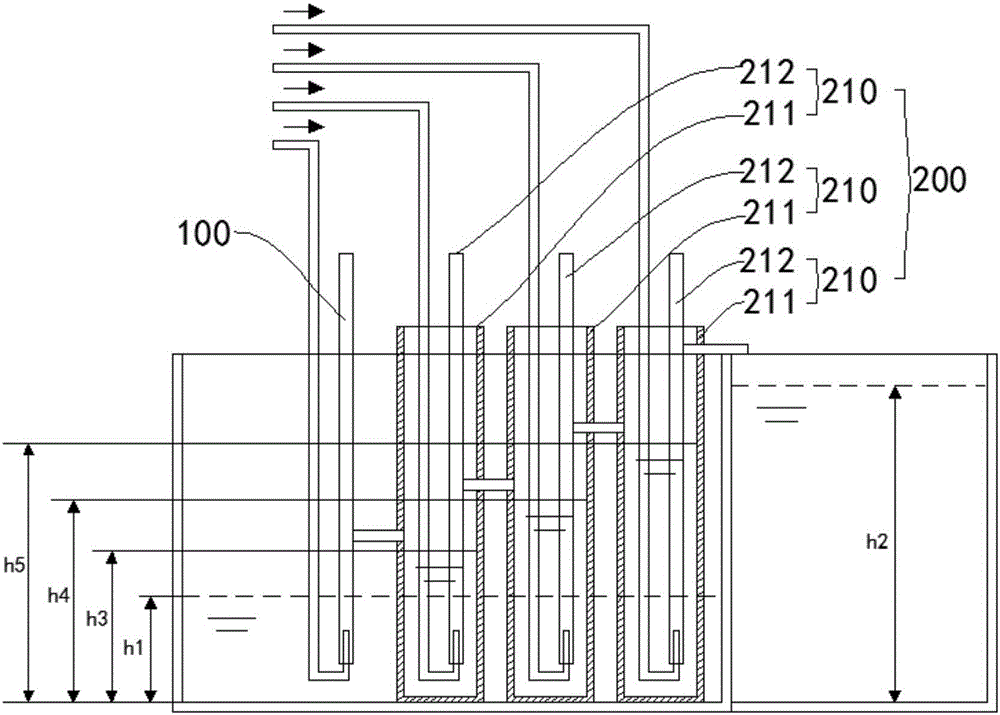

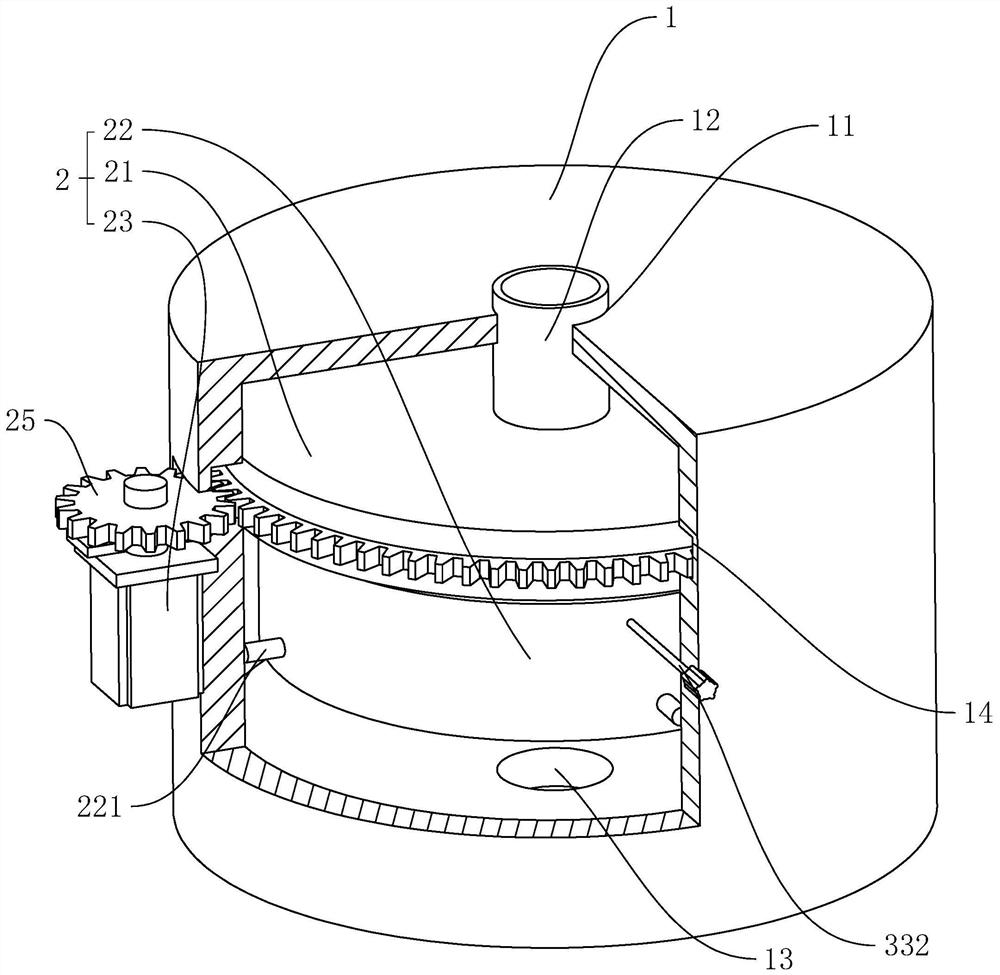

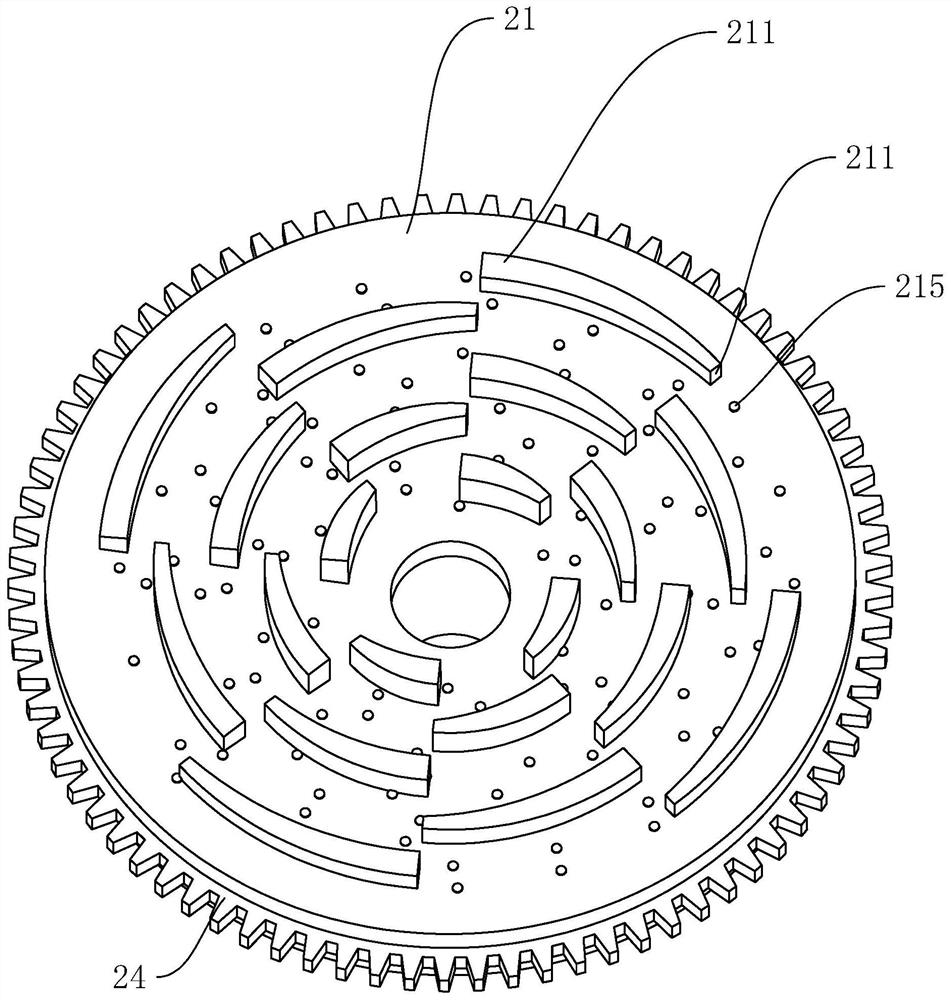

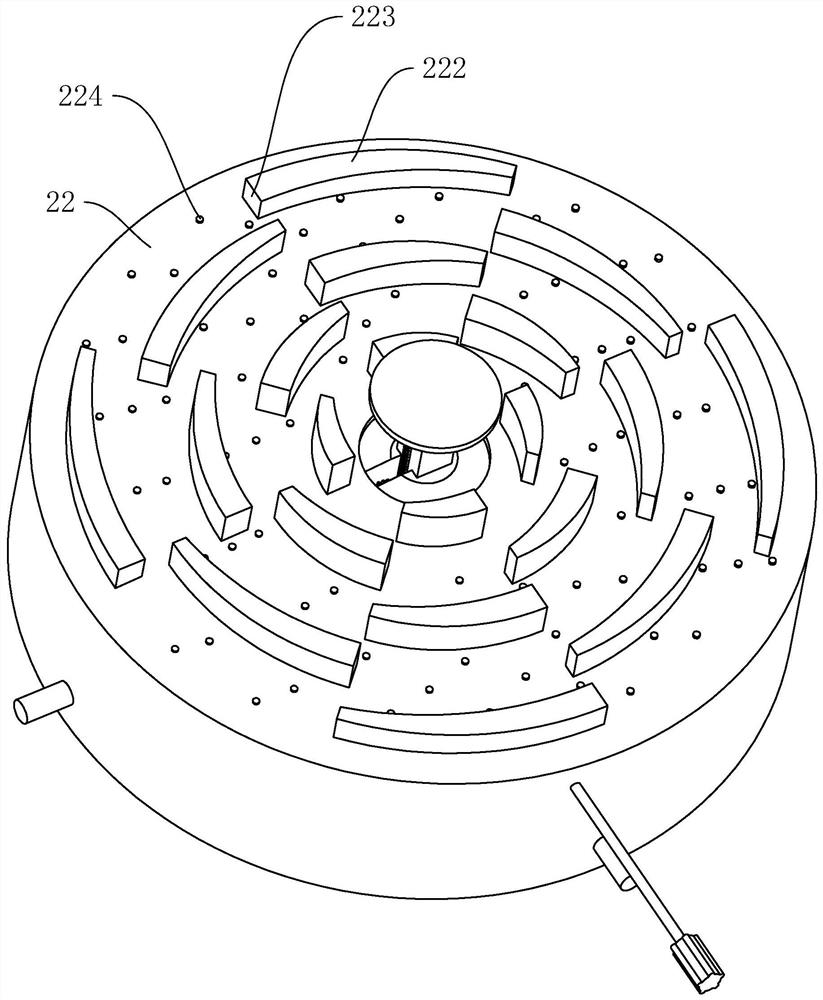

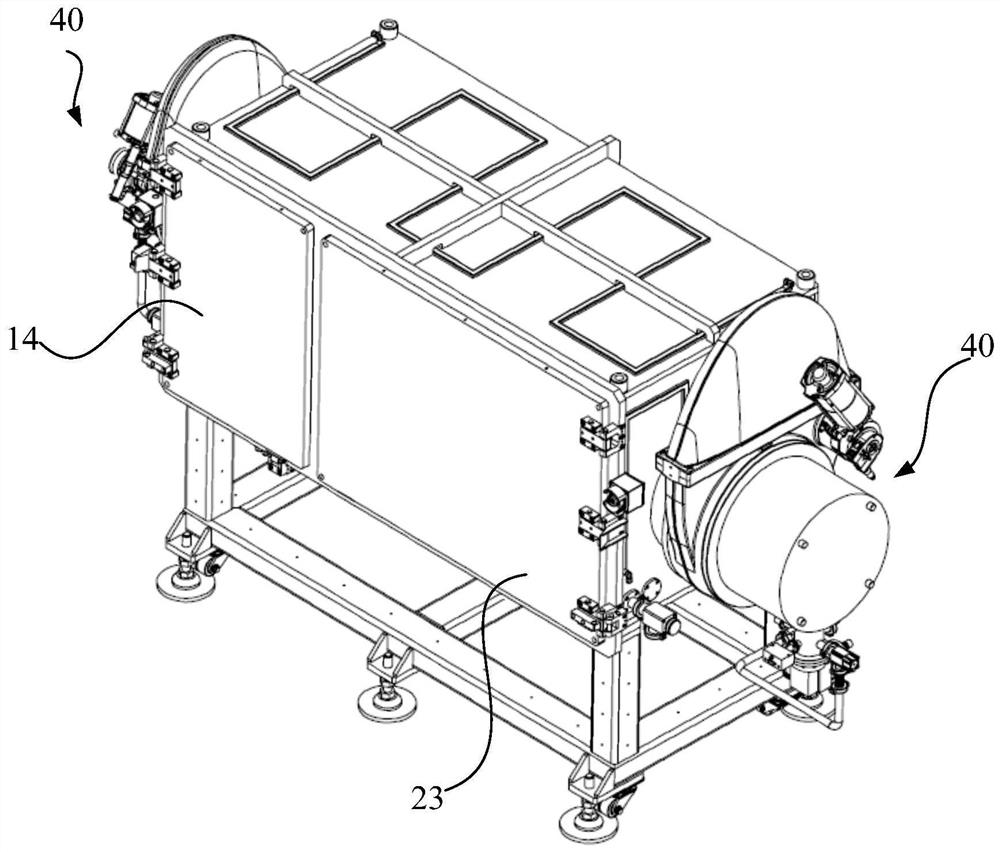

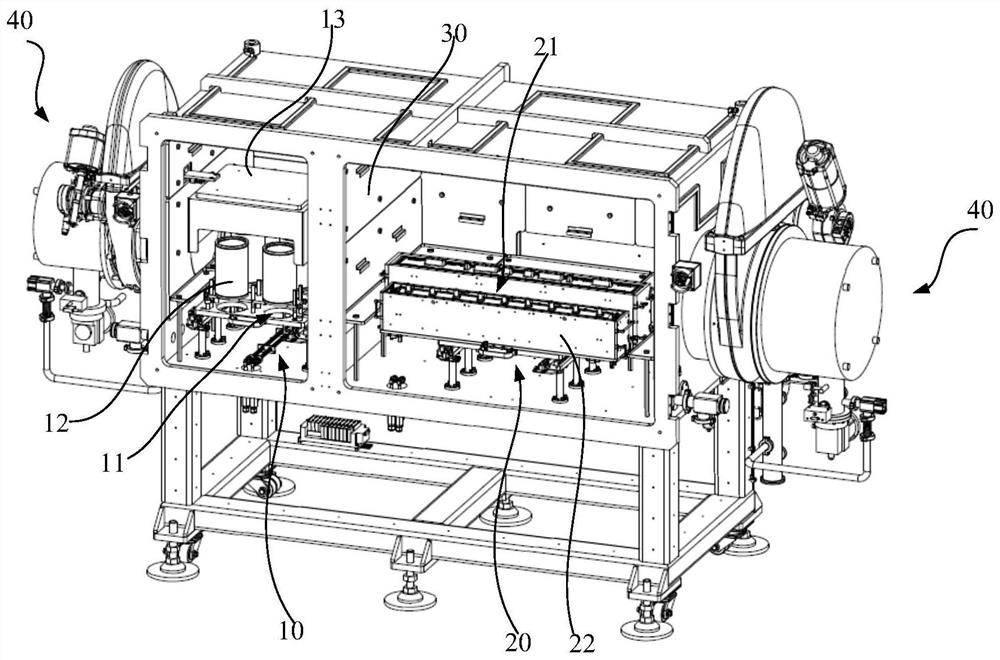

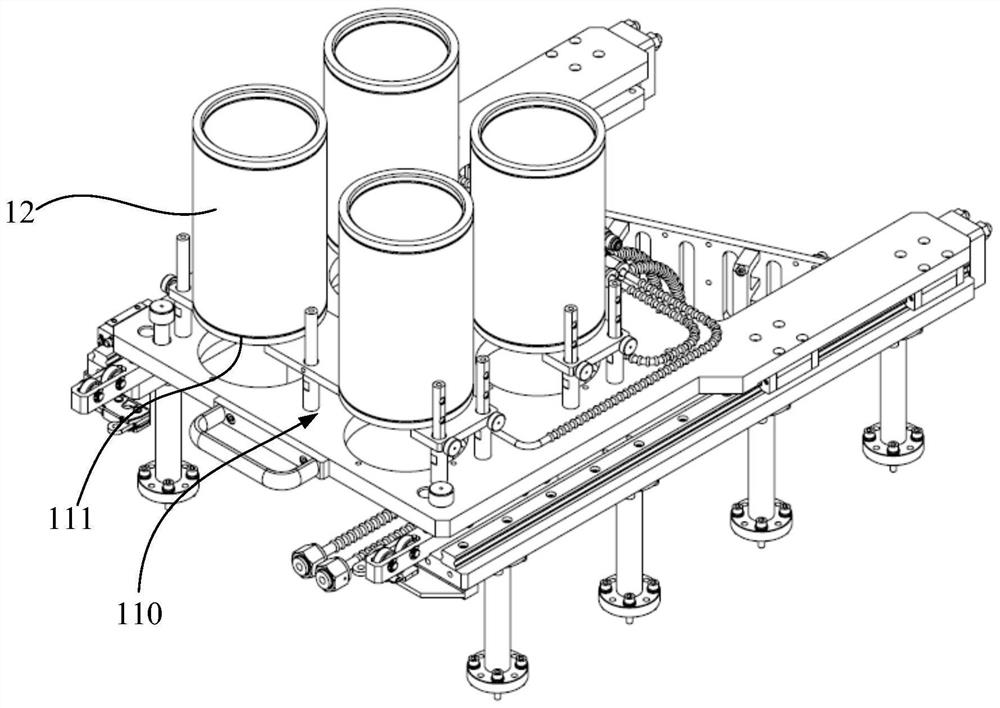

Evaporation source cleaning equipment and evaporation system

ActiveCN110016647AProcess impactClean thoroughlyVacuum evaporation coatingSputtering coatingEvaporationEngineering

The invention discloses evaporation source cleaning equipment and an evaporation system. The evaporation source cleaning equipment comprises a vacuum cavity and further comprises a first evaporation source heating unit and a second evaporation source heating unit which are arranged in the vacuum cavity. The first evaporation source heating unit comprises a supporting part used for containing at least one point evaporation source. Heat radiation can be generated in the first evaporation source heating unit so as to clean the point evaporation source. The second evaporation source heating unit and the first evaporation source heating unit are distributed in a spaced manner. The second evaporation source heating unit comprises at least one containing groove for containing a line evaporation source or a face evaporation source, wherein the containing groove can generate heat radiation for cleaning of the line evaporation source or the face evaporation source. According to the disclosed evaporation source cleaning equipment, impurities of the point evaporation source, the line evaporation source and the face evaporation source can be removed, influences on the evaporation cavity technology are avoided, the evaporation efficiency can be improved, and the activation rate of the evaporation system is increased.

Owner:KUNSHAN GO VISIONOX OPTO ELECTRONICS CO LTD

Method of manufacturing semiconductor devices and corresponding semiconductor device

PendingCN111354646AEasy to useProcess has no effectSemiconductor/solid-state device detailsSolid-state devicesEpoxyDevice material

The invention relates to a method of manufacturing semiconductor devices and corresponding semiconductor devices. A semiconductor chip is mounted on a leadframe. A first portion of an insulating package for the semiconductor chip is formed from laser direct structuring (LDS) material molded onto the semiconductor chip. A conductive formation (provided by laser-drilling the LDS material and plating) extends between the outer surface of the first portion of insulating package and the semiconductor chip. An electrically conductive clip is applied onto the outer surface of the first portion of theinsulating package, with the electrically conductive clip electrically coupled to the conductive formation and the leadframe. A second portion of the insulating package is made from package molding material (epoxy compound) molded onto the electrically conductive clip and applied onto the outer surface of the first portion of the insulating package.

Owner:STMICROELECTRONICS SRL

Activity control method of in-situ decoking material of aromatic hydrocarbon deolefination catalyst and application thereof

ActiveCN112642476AShort resurrection timeSecurity risks are controllableMolecular sieve catalystsCatalyst regeneration/reactivationProcess engineeringSimple Organic Compounds

The invention discloses an activity control method of an in-situ decoking material of an aromatic hydrocarbon deolefination catalyst and application thereof. The method comprises the step of contacting a soluble coke material with a catalyst subjected to an aromatic hydrocarbon olefin removal refining reaction, wherein the bubble point of the soluble coke material in a standard state is below 90 DEG C, and the soluble coke material is one or a mixture of aliphatic hydrocarbon and an oxygen-containing organic compound. The invention mainly solves the problems of long regeneration period, large activity loss, short total service life and large catalyst hazardous waste amount caused by out-of-device regeneration required by the existing olefin removal catalyst. The method provided by the invention has the characteristics of simple regeneration, low cost, excellent reactivation restorability and multiple reactivation, and can be used for industrial application.

Owner:CHINA PETROLEUM & CHEM CORP +1

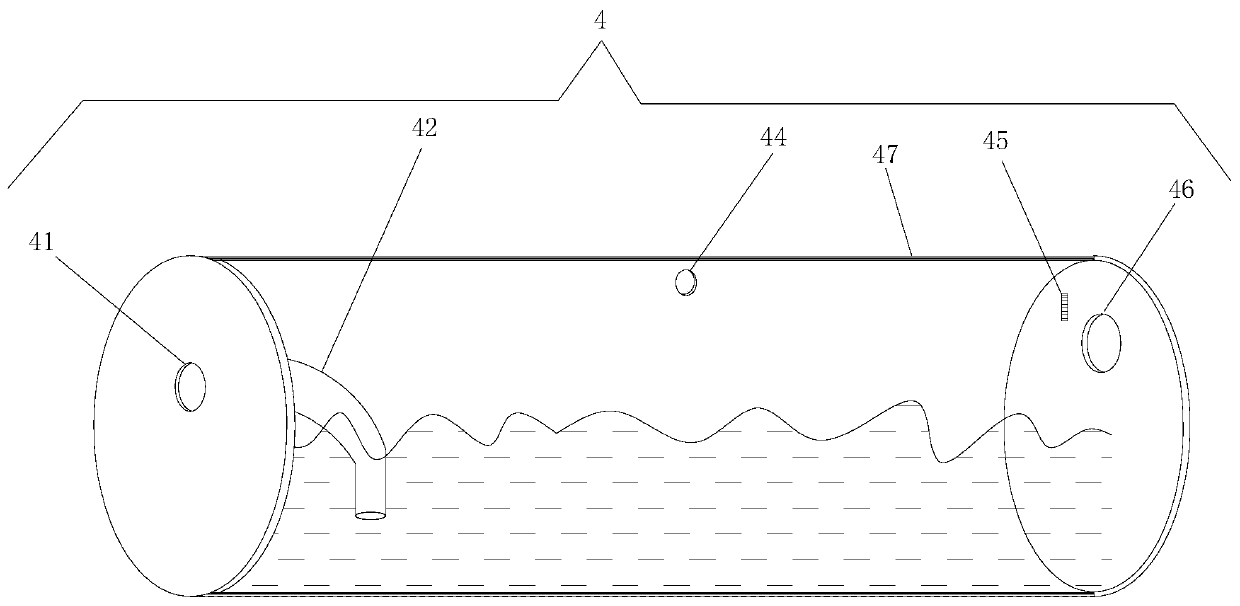

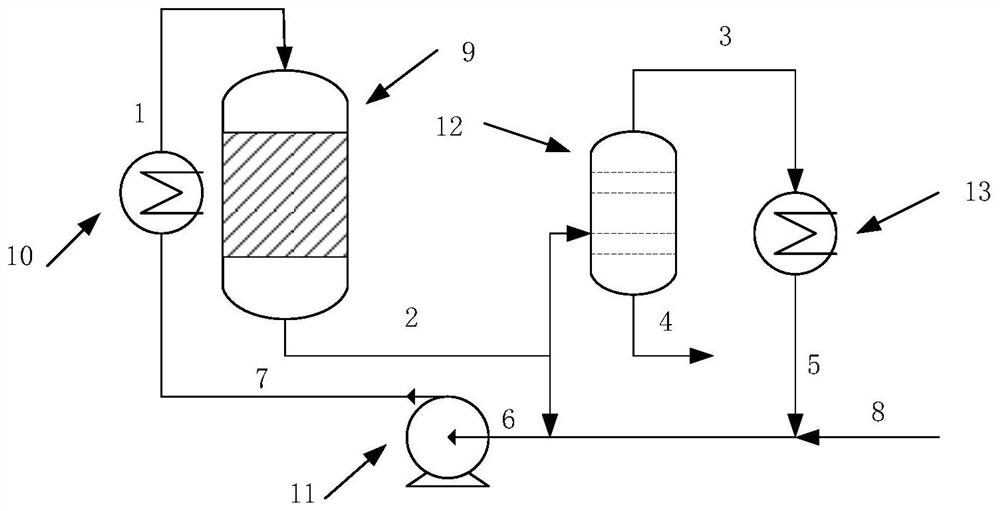

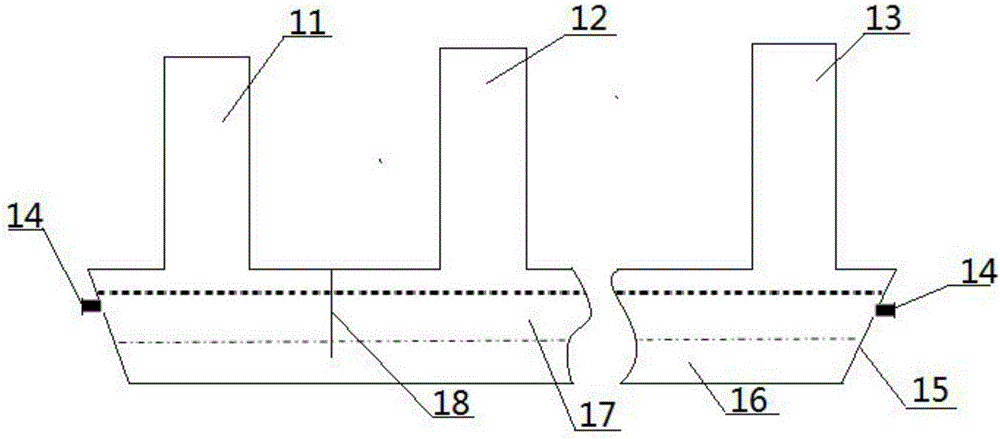

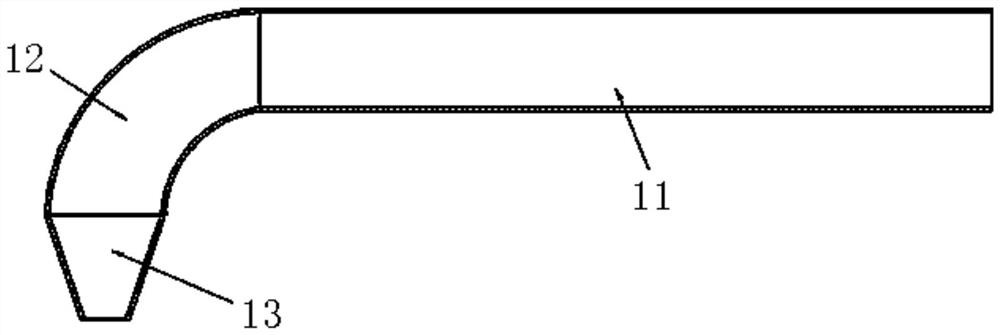

Sewage lifting equipment

The invention relates to sewage lifting equipment. The sewage lifting equipment comprises a gas source, a first gas lifting pipe and a sewage multistage lifting structure used for conducting multistage lifting on sewage output by the first gas lifting pipe; the sewage multistage lifting structure is composed of multiple single-stage sewage lifting members; the single-stage sewage lifting members are sequentially connected in a matched mode to form multistage lifting. The sewage lifting equipment has the advantages that when the required sewage lifting height is 1.5 times larger than the height of the liquid level line of to-be-lifted sewage in a sewage tank, lifting can still be conducted; meanwhile, the gas source is only used as power in the whole equipment, the whole structure of the sewage lifting equipment is simplified, use of other equipment is reduced, and the energy is saved; in the sewage lifting process, the lifting flow of the sewage can be changed by adjusting the gas supply quantity of the gas source, and therefore the situation that due to the fact that the flow is too large, the next sewage treatment process is affected is effectively avoided.

Owner:WUHAN XINGTIANYU ENVIRONMENTAL ENG

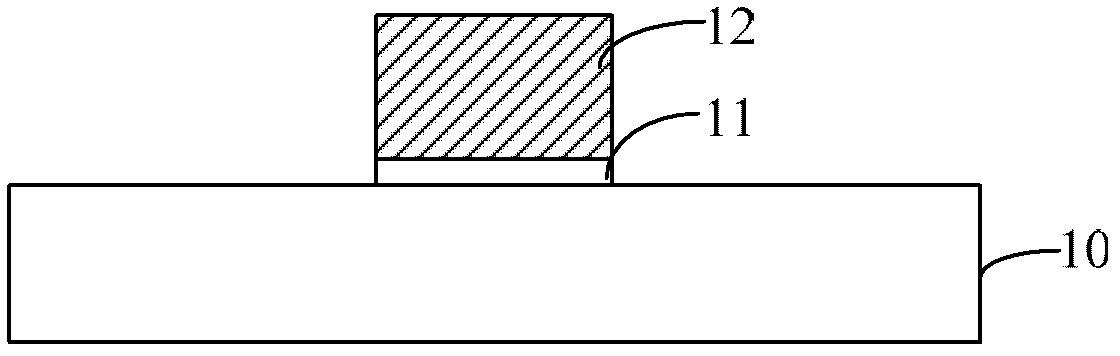

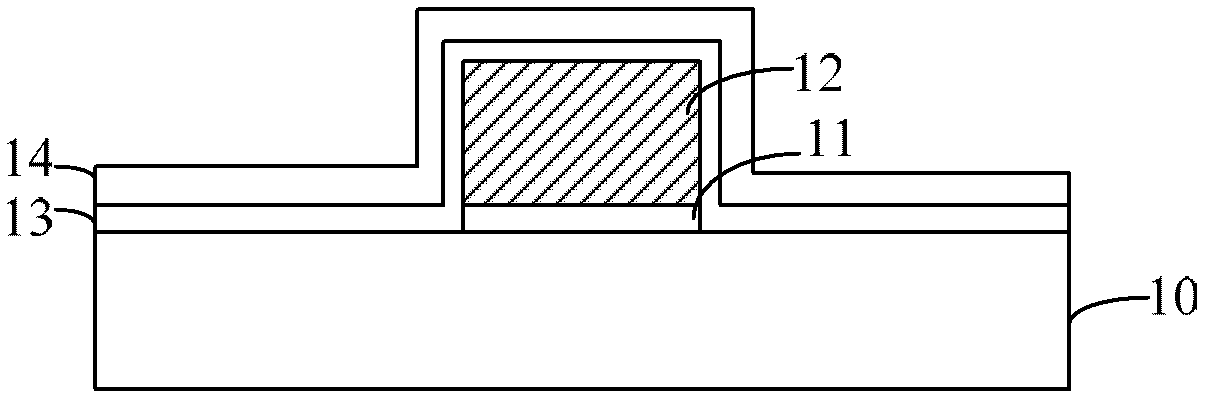

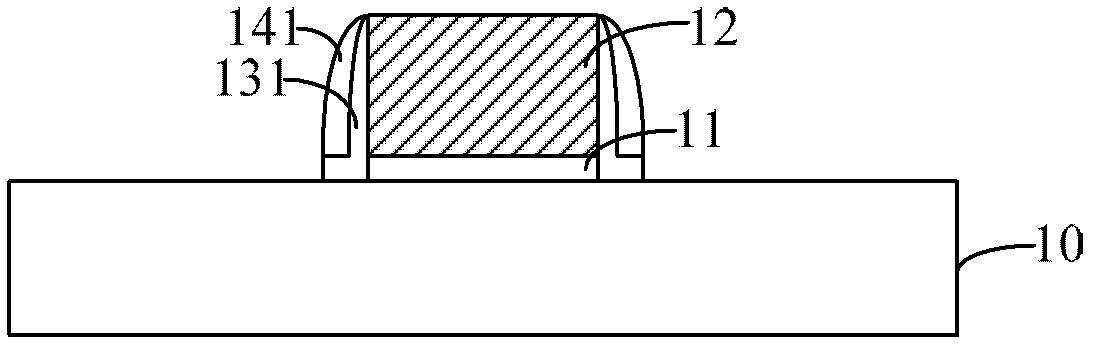

Side wall and method for forming side wall and semiconductor

ActiveCN102637604AAvoid failureReduce lossesSemiconductor/solid-state device manufacturingGate dielectricMetal silicide

The invention relates to a side wall and a method for forming the side wall and a semiconductor. The method for forming the side wall comprises the following steps of: providing a substrate with a grid electrode structure, wherein the grid electrode structure comprises a grid electrode and a gate dielectric layer which is located between the grid electrode and the substrate; forming a first dielectric layer which covers the substrate and the gate dielectric layer and is a single-layer or laminated structure; forming a second dielectric layer on the first dielectric layer, wherein the corrosion resistance of the second dielectric layer on an etching liquid used in the process of forming a self-alignment metal silicide block is more than that of the outermost layer material of the first dielectric layer on the etching liquid; and sequentially etching the second dielectric layer and the first dielectric layer to form the side wall at the periphery of the grid electrode. The side wall formed in the invention has large corrosion resistance on a solution utilized in the washing process of the formed side wall, thus the loss of the side wall in the process of forming the self-alignment metal silicide block can be reduced, the corresponding side wall width is increased, and the field effect transistor failure problem caused by too small side wall can be avoided.

Owner:SHANGHAI HUAHONG GRACE SEMICON MFG CORP

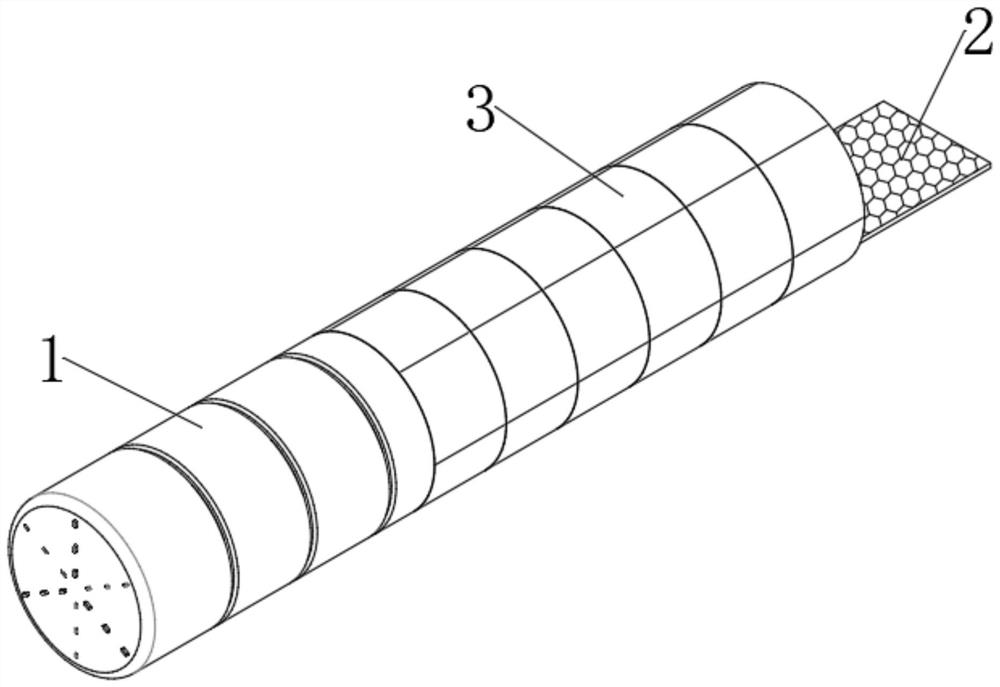

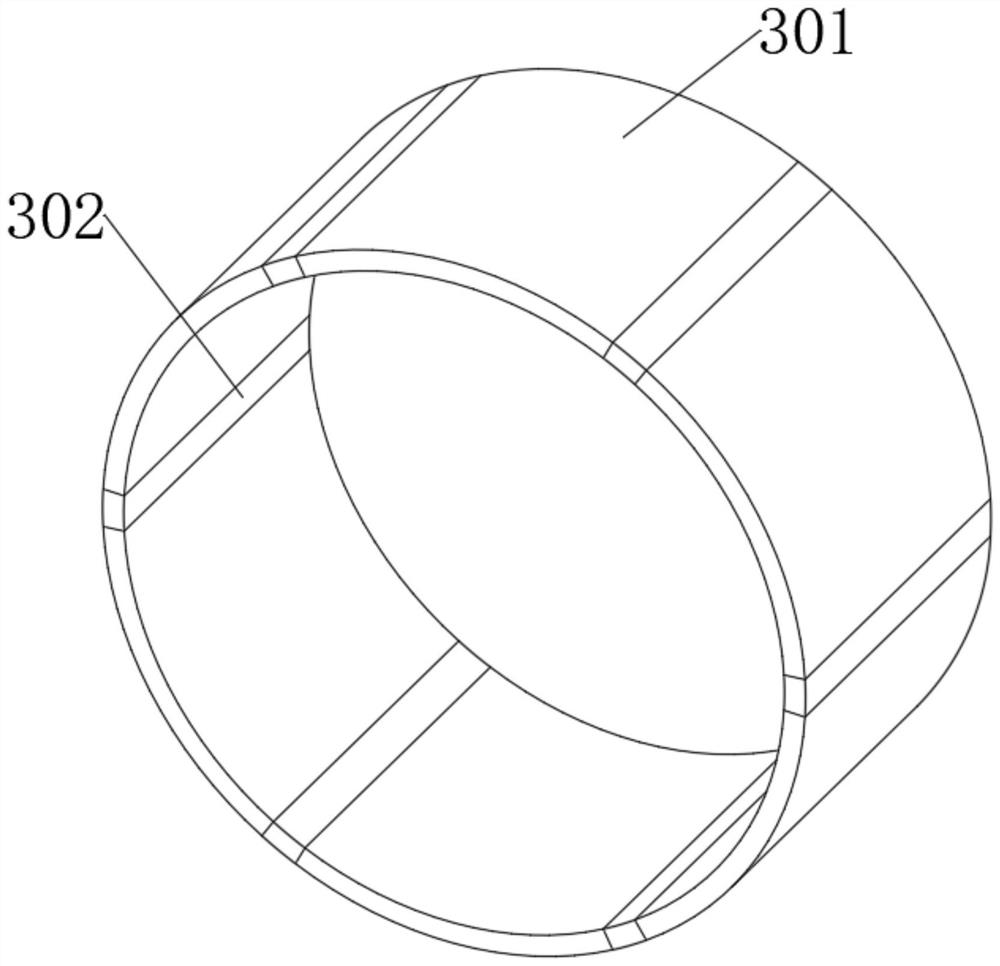

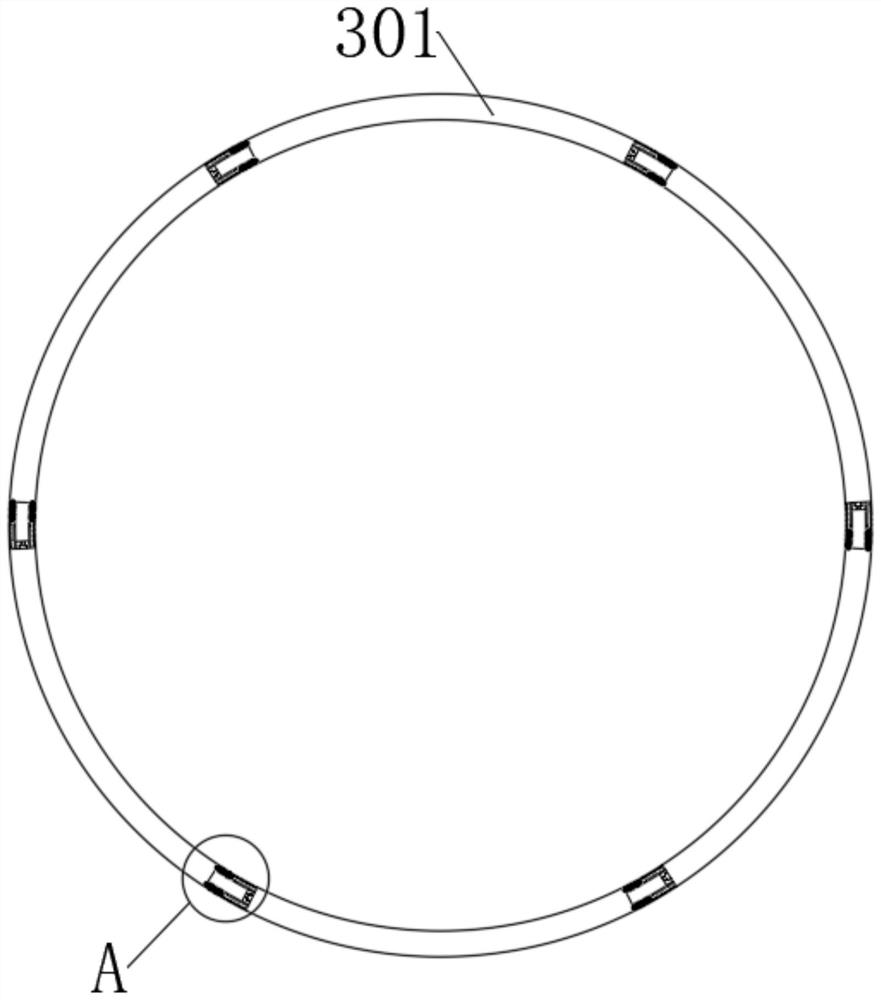

Pipe piece used for shield construction and process for assembling pipe piece into ring

InactiveCN113236292AQuick mixPlay a bonding effectUnderground chambersTunnel liningLiquid waterAdhesive

The invention discloses a pipe piece used for shield construction and a process for assembling the pipe piece into a ring, belongs to the field of pipe pieces for shield construction, and provides the pipe piece used for shield construction and the process for assembling the pipe piece into the ring. According to the scheme, a ceramic adhesive is used for replacing traditional bolts to carry out fixation on adjacent pipe pieces, every two adjacent pipe piece rings are connected through the bolts, that is, every two adjacent pipe piece rings abut against each other under the action of a shield tunneling machine, excessive connection is not needed to be carried out, in the process that splicing is carried out on the pipe pieces, pressing is carried out on adjacent elastic gaskets by utilizing the weight of concrete slabs, and therefore liquid water and the ceramic adhesive can be rapidly mixed, hardening is carried out to achieve the bonding effect, the working intensity of workers in the shield construction process can be greatly reduced, the workers can carry out long-time construction along with a shield, the single working hour of the workers is increased, and the whole shield construction process is not prone to being affected.

Owner:刘飞

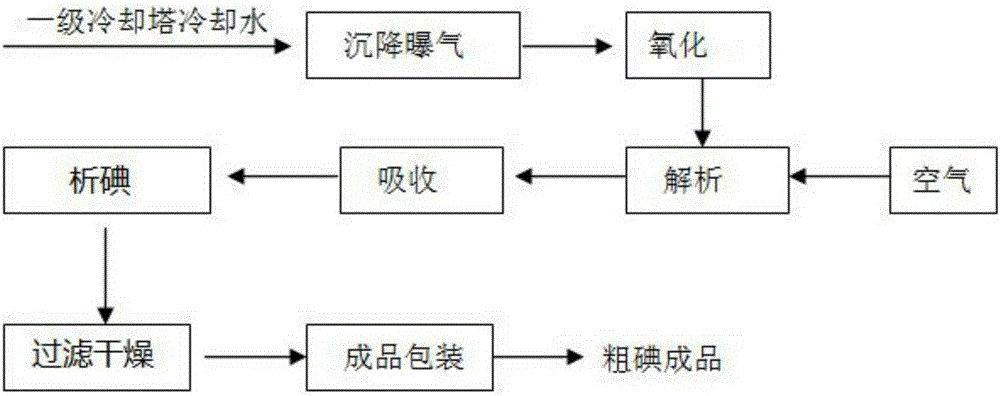

Method and device for recycling iodine from cooling water in first cooling tower used in yellow phosphorus production and used cooling tower

The invention relates to the technology of recycling iodine in yellow phosphorus production, especially to a method and device for recycling iodine from cooling water in a first cooling tower used in yellow phosphorus production and the used cooling tower. The method includes sending the cooling water in the first cooling tower used in yellow phosphorus production to a settlement aeration tank to overflow to an oxidation tank, adding an oxidizing agent to oxidize to iodate, analyzing, and absorbing by a reducing agent. The method can improve the recovery rate of iodine. The modified cooling structure can make the cooling water in the first cooling tower perform settlement processing in the settling tank preferentially, which can reduce the circulation volume of the solution absorbed circularly, reduce the energy consumption, shorten the processing period of recycling iodine and reduce the recovery cost. Moreover, the liquid with high density from the first cooling tower is recycled preferentially, the recovery rate of iodine is improved, the enriching step of recycling iodine in yellow phosphorus production is avoided, and the cost is reduced.

Owner:贵州鑫新实业控股集团有限责任公司

A garbage disposal device

The invention relates to a garbage disposal device, which comprises a hollow casing, a crushing mechanism is arranged inside the casing, a lower crushing disk, an upper crushing disk and a motor of the crushing mechanism, and several upper crushing rings are coaxially arranged at the lower end of the upper crushing disk. The lower end of the upper crushing ring is provided with several upper crushing grooves in the circumferential direction. The upper crushing grooves penetrate the side wall of the upper crushing ring. There is a gap between the outer wall of the lower crushing disc and the inner wall of the shell. The upper end of the lower crushing ring is provided with several lower crushing grooves in the circumferential direction, the lower crushing grooves penetrate the side wall of the lower crushing ring, the lower crushing ring is inserted in the gap between the upper crushing rings, and the upper end of the shell is pierced with a feeding hole , the lower end of the housing is penetrated with a feeding hole connected with the inner cavity, and the upper part of the upper crushing disc is coaxially penetrated with a feeding hole. The relative movement between the upper crushing ring and the lower crushing ring is used to cut off the food waste, and the rigid contact between the two can process relatively hard food waste.

Owner:深圳市华富环境有限公司

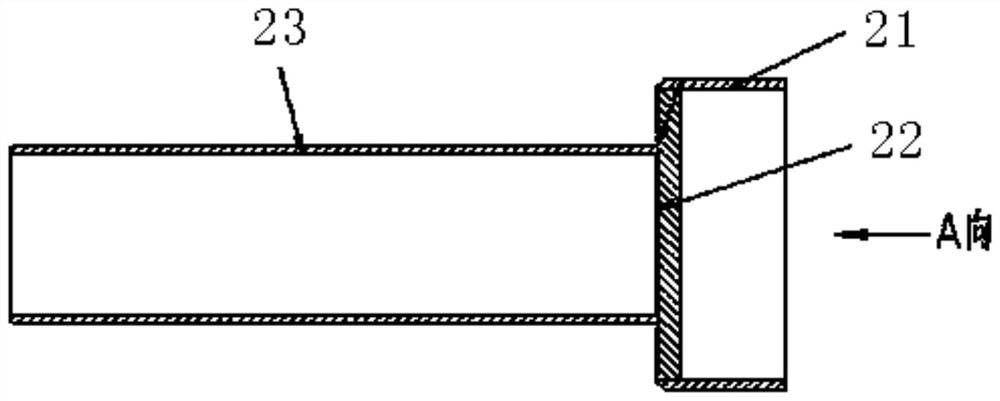

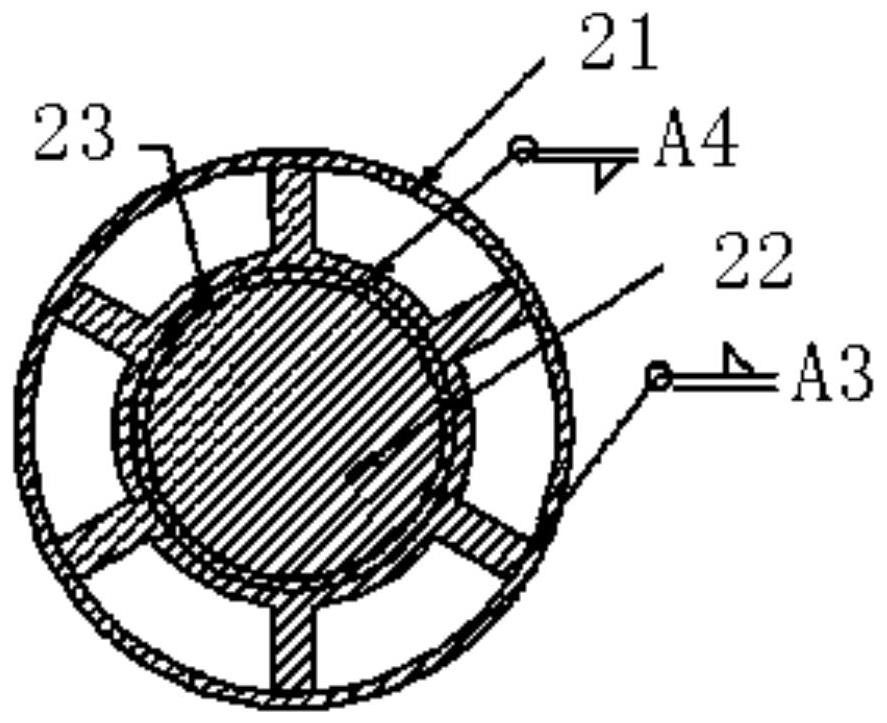

Evaporation source cleaning equipment and evaporation system

ActiveCN110016647BProcess impactClean thoroughlyVacuum evaporation coatingSputtering coatingEvaporation (deposition)Engineering

Disclosed is a vapor deposition source cleaning device, comprising: a vacuum chamber; a first vapor deposition source heating unit (11) arranged in the vacuum chamber, wherein the first vapor deposition source heating unit (11) comprises a support part (110), the support part (110) is used for the placing of at least one punctiform vapor deposition source, and the first vapor deposition source heating unit (11) is capable of providing thermal radiation for cleaning the punctiform vapor deposition source; and a second vapor deposition source heating unit (21) arranged in the vacuum chamber and spaced apart from the first vapor deposition source heating unit (11), wherein the second vapor deposition source heating unit (21) comprises at least one accommodating groove (211) used for the placing of a linear vapor deposition source or a planar vapor deposition source, and the accommodating groove (211) is capable of providing thermal radiation for cleaning the linear vapor deposition source or the planar vapor deposition source placed in the accommodating groove. Further disclosed is a vapor deposition system.

Owner:KUNSHAN GO VISIONOX OPTO ELECTRONICS CO LTD

A method and device for displaying documents in a browser

ActiveCN103955466BProcess impactPlatform integrity maintainanceSpecial data processing applicationsDocumentationVirus

Owner:BEIJING QIHOO TECH CO LTD

Method and device for displaying document in browser

ActiveCN102622439BProcess impactPlatform integrity maintainanceSpecial data processing applicationsDocumentationComputer science

The invention provides a method and a device for displaying a document in a browser. The method comprises the following steps that: a browser host process establishes a plug-in separate process of a corresponding document processing procedure according to a request for accessing the document of a user, wherein the plug-in separate process is a subprocess of the browser host process; the plug-in separate process initiates a browser page; and the browser page calls a plug-in of the document processing procedure to analyze the document and display the page. By the method and the device, the influence of the vulnerability of the document processing procedure on the application of the browser can be avoided, and a user computer is further prevented from being attacked by virus.

Owner:BEIJING QIHOO TECH CO LTD

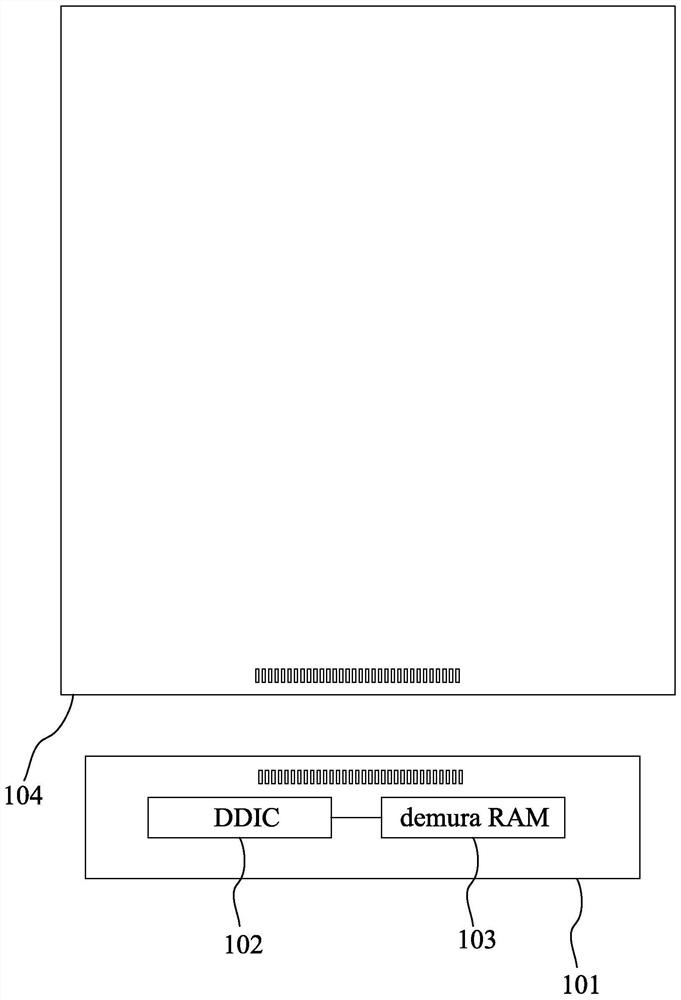

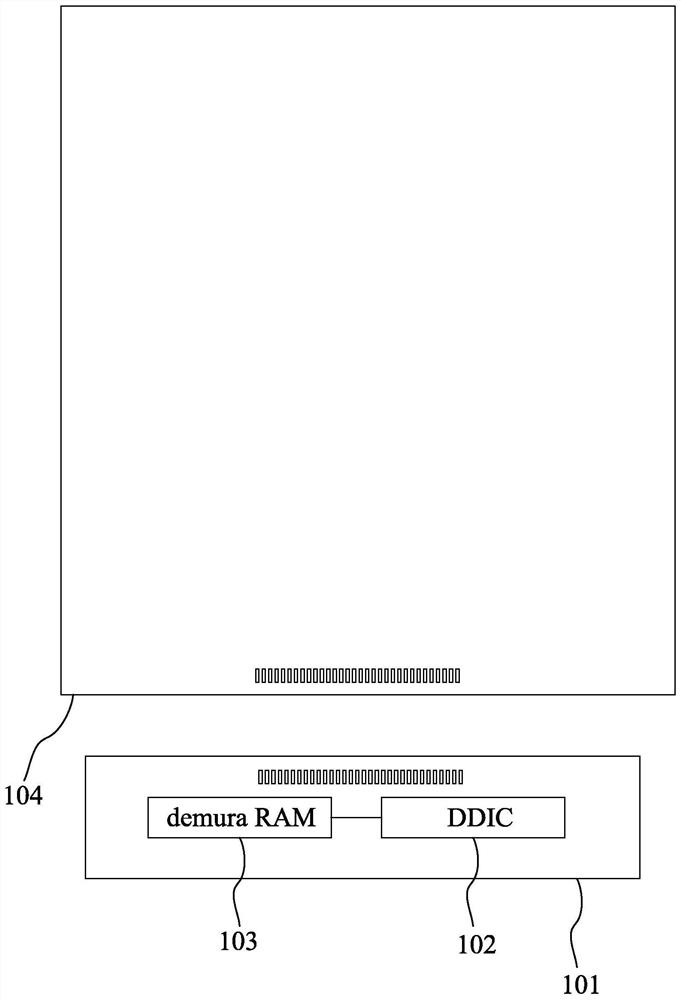

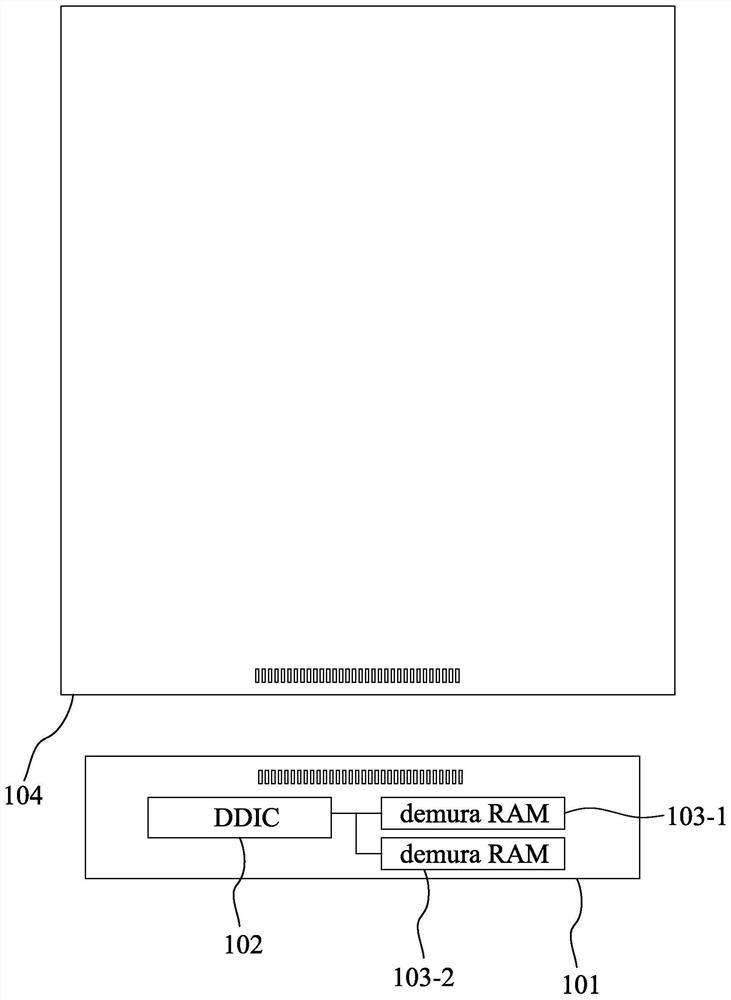

Display driving circuit system

The invention provides a display driving circuit system. The display driving circuit system comprises a flexible circuit board, a brightness compensation memory (emura RAM) and a display driving integrated circuit. The flexible circuit board is electrically connected with the display panel. The brightness compensation memory is configured on the flexible circuit board. The display driving integrated circuit is arranged on the flexible circuit board and is provided with a rectangular structure, a first side of the display driving integrated circuit is electrically connected with the brightness compensation memory, the first side is a short side of the rectangular structure of the display driving integrated circuit, and the brightness compensation memory is arranged on the first side of the display driving integrated circuit.

Owner:FOCALTECH ELECTRONICS

Wireless charging system and method for electric vehicle to electric vehicle

ActiveCN104638694BImprove securityImprove reliabilityBatteries circuit arrangementsSecondary cells charging/dischargingPower batteryElectricity

The invention discloses a wireless charging system for electric cars and a control method of the wireless charging system. The system comprises an electric energy providing device, an electric energy receiving device and a battery management device, wherein the battery management device comprises a first battery manager and a second battery manager, and the electric energy providing device is used for transmitting electric energy to the electric energy receiving device; the electric energy receiving device uses the electric energy provided by the electric energy providing device to charge a second power battery; the first battery manager is used for controlling the wireless charging flow of the electric energy providing device; the second battery manager is used for controlling the wireless charging flow of the electric energy receiving device. The wireless charging system has the advantages that wireless charging between the electric cars can be achieved, high safety and reliability are achieved, charging is simple and practicable, the service life of charging equipment can be prolonged by the wireless charging manner, and high applicability is achieved.

Owner:BYD CO LTD

Reaction chamber and plasma processing equipment

ActiveCN104746043BAvoid formingProcess impactChemical vapor deposition coatingPlasma techniqueMetallic materialsEngineering

The invention provides a reaction chamber and plasma processing equipment. The reaction chamber includes a Faraday shield, an insulating ring and a shielding ring made of a non-magnetic metal material, which are sleeved on the inside of the side wall of the reaction chamber. The shield is stacked on the insulating ring, at least one slit is arranged at intervals along the circumference of the Faraday shield, and the slit is arranged along the vertical direction of the Faraday shield, and the shielding ring surrounds the joint between the Faraday shield and the insulating ring The inner side is not in contact with the Faraday shield and is grounded; the shielding ring is used to shield the metal ions in the reaction chamber from depositing at the connection between the slot and the insulating ring. The reaction chamber provided by the invention can improve the stability of the process in the reaction chamber, thereby improving the process quality.

Owner:BEIJING NAURA MICROELECTRONICS EQUIP CO LTD

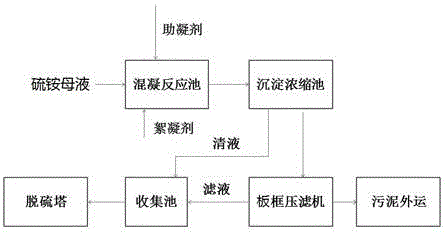

A method for purifying ammonium sulfate mother liquor produced by sintering flue gas ammonia desulfurization process

InactiveCN103007588BMeet filter requirementsPH effectDispersed particle separationSedimentation separationAluminium chlorideFiltration

The invention relates to a method for purifying ammonium sulfate mother liquor produced from sintering flue gas through an ammonia method desulfurization process. The method is characterized by comprising the following steps: adding an inorganic high-polymer flocculant polyaluminium chloride or polyaluminum sulfate into the ammonium sulfate mother liquor at 10-45 DEG C, stirring, dispersing, then adding a high-polymer coagulant aid for improving the structure of the flocculant, stirring, dispersing, further standing, fully precipitating, collecting the supernatant (namely the treated ammonium sulfate mother liquor), then performing pressure filtration on the lower-layer precipitate by using a plate-frame type pressure filter, collecting the filtrate (namely the treated ammonium sulfate mother liquor) obtained by pressure filtration, and merging with the collected supernatant. The process is simple, and the purification effect is good; the treated ammonium sulfate mother liquor system has no residues of the flocculant and the coagulant aid basically, and when the ammonium sulfate mother liquor system is returned into a desulfurizing tower for repeated use, adverse effects on the process in the desulfurizing tower can be avoided; and the cost is low, and the popularization is convenient to realize.

Owner:武汉钢铁有限公司

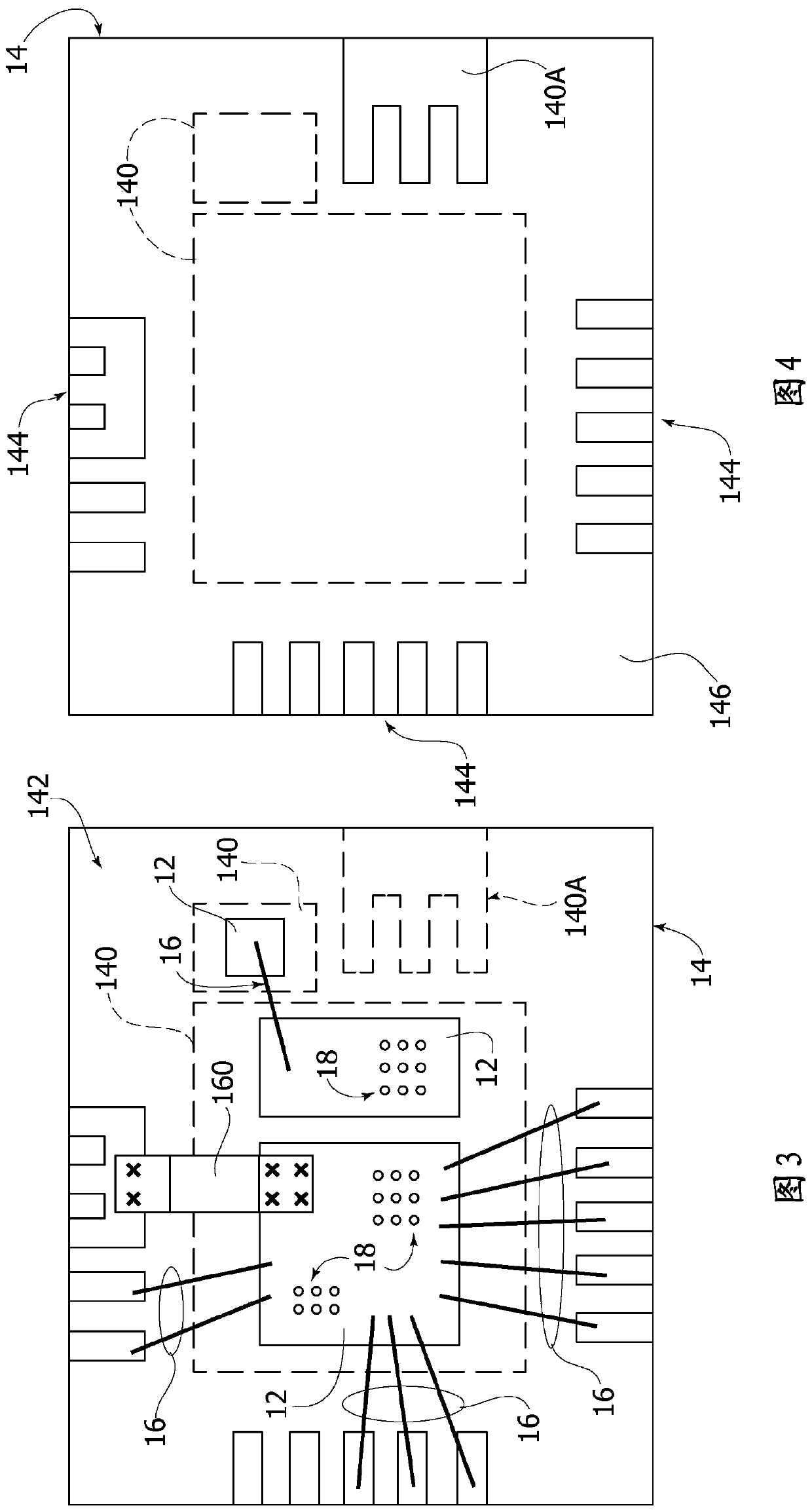

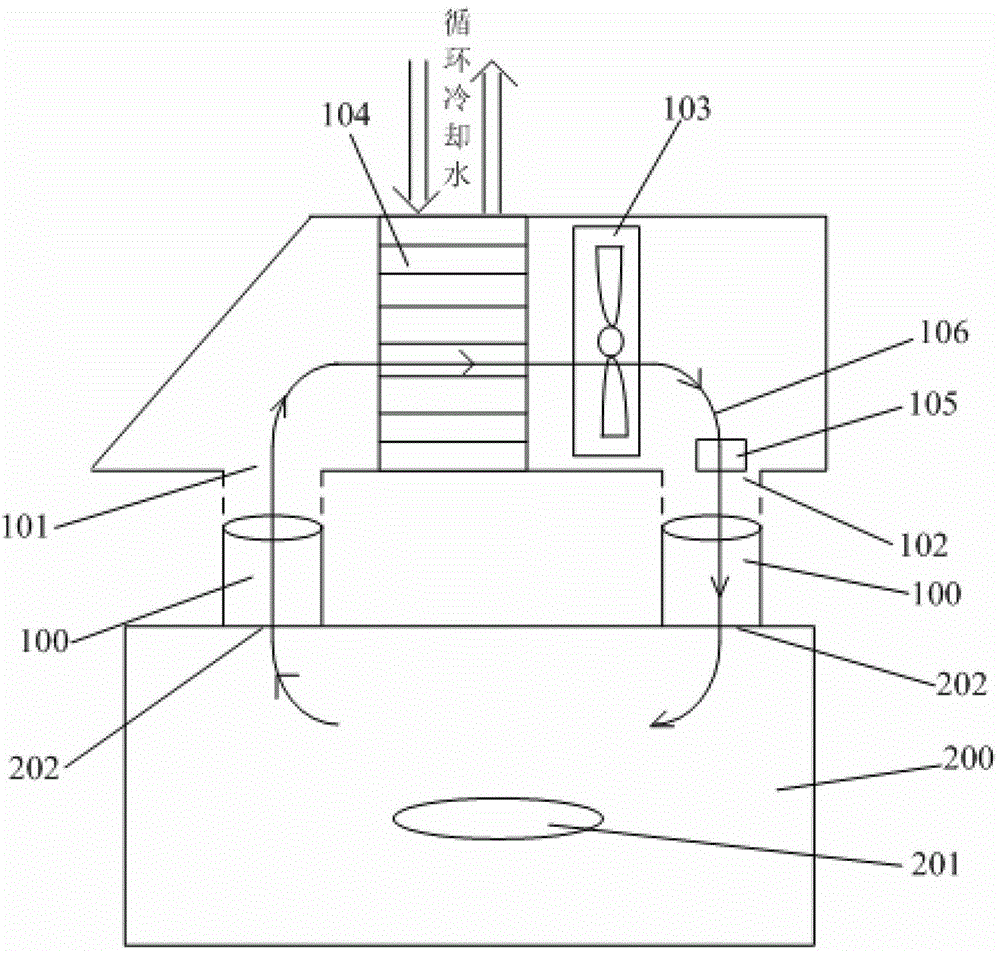

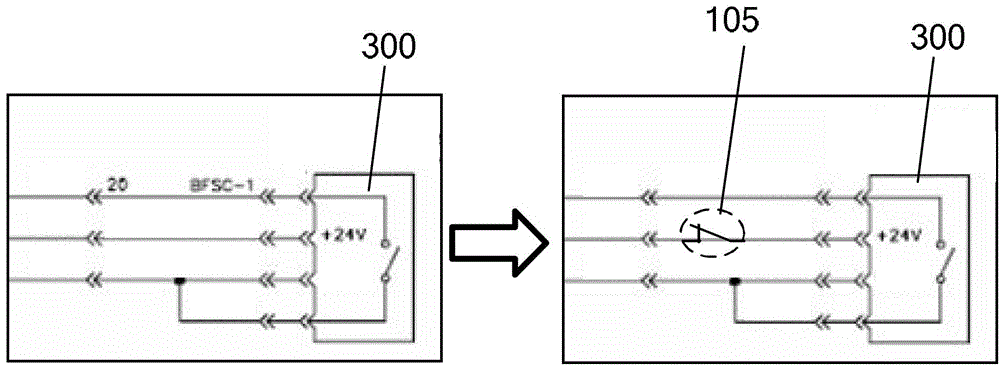

Heat exchange system and method for high-temperature semiconductor process equipment

ActiveCN103278029BRealize acquisitionProcess impactStationary conduit assembliesHeat exchange apparatusEngineeringHot Temperature

The invention provides a heat exchange system and a heat exchange method for a machine with high-temperature semiconductor process. The heat exchange system is connected with two ventilation ports of a reaction chamber of the machine and comprises an air inlet, an air outlet, a heat exchanger, a blower at the air outlet and a heat sensor. Hot air discharged from the reaction chamber enters the air inlet, sequentially passes through the heat exchanger, the heat sensor and the air outlet, and is driven into the reaction chamber by the blower at the air outlet. The heat exchanger is used for cooling the hot air. The heat sensor is used for acquiring the temperature of the air cooled by the heat exchanger. When the acquired temperature of the cooled air is higher than a preset value, heat exchange is stopped. By the heat sensor, errors and inefficiency, which influence semiconductor process, of heat exchange are avoided.

Owner:SHANGHAI HUAHONG GRACE SEMICON MFG CORP

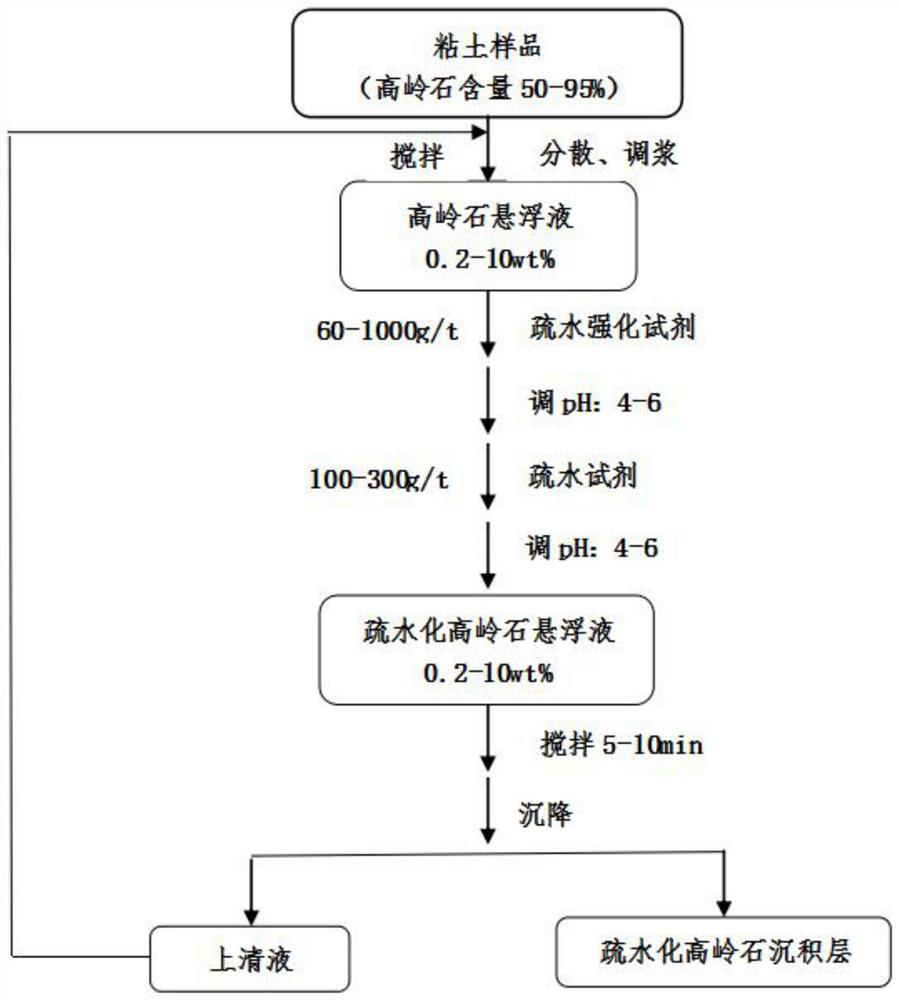

Method for enhancing hydrophobic agglomeration of suspended clay mineral-fine-grained kaolinite in water body

InactiveCN111704264ASimple processSignificant reunionWaste water treatment from quariesMultistage water/sewage treatmentClay mineralsKaolinite

The invention discloses a method for enhancing hydrophobic agglomeration of suspended clay minerals-fine-grained kaolinite in a water body, and belongs to the technical field of beneficiation environment treatment. The method disclosed by the invention comprises the following steps: adding a hydrophobic agglomeration strengthening reagent into a suspension according to a proportion of 60 -1000 g / t, controlling the pH value of the suspension to be 4-6, and stirring the suspension for 5-10 minutes at normal temperature; then adding a dodecylamine solution into the suspension according to the proportion of 100-300 g / t, keeping the pH of the suspension at 4-6, and continuously stirring the suspension for 5-10 minutes; and standing the suspension for quickly settling the kaolinite particles, and carrying out solid-liquid separation. The method is used for promoting agglomeration and accelerated sedimentation of fine-grained kaolinite (20 microns) in mineral separation and metallurgy tailingwater, and can enable the Stokes equivalent particle size of the fine-grained kaolinite aggregate in the suspension to reach 86 microns or above, the sedimentation speed to reach 22.9 m / h and the sedimentation rate to reach 95%.

Owner:KUNMING UNIV OF SCI & TECH

Preparation method of flue gas bipolar heat exchanger for radiant tube burner

PendingCN114857983ASimple manufacturing processThe process is independent of each otherWelding/cutting auxillary devicesAuxillary welding devicesFlue gasProcess engineering

The invention discloses a preparation method of a flue gas bipolar heat exchanger for a radiant tube burner, which comprises the following steps: respectively and independently assembling and welding three assemblies, namely an internal finned tube assembly, a flue gas cavity assembly and an air inlet connecting tube assembly, respectively carrying out airtight detection after welding, and then, firstly sleeving the flue gas cavity assembly into the internal finned tube assembly; and then the smoke cavity assembly is connected with the connecting flange, on the outer side of the connecting flange, the flange of the air inlet connecting pipe assembly is connected with the outer side of the connecting flange, and assembling can be completed. The manufacturing process is simple and efficient, the working procedures do not restrain each other, production is flexible, and the situation that the whole working procedure is affected due to stagnation of one working procedure is avoided; the delivery state of finished products is flexible and variable, and the finished products can be transported to an installation site after being assembled in a manufacturing factory and can also be packaged and transported in a classified mode according to assemblies and flexibly assembled on the installation site; the technical key points are clear and controllable, and the production efficiency and the product quality are greatly improved; and the productivity efficiency in the process assembling and welding process is high, and 100 machines can be achieved by 5 persons per 16 shifts.

Owner:QINGDAO NPA IND

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com