Apparatus for measuring temperature of substrate and the method thereof

A temperature measurement and substrate technology, applied in measuring devices, measuring heat, thermometers, etc., can solve the problems of process yield reduction, difficulty in adjusting the process environment and ensuring yield, time waste, etc., to reduce the incidence of defects and alleviate the impact , the effect of increasing the yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0059] Hereinafter, the structure and function of the substrate processing apparatus according to the present invention will be described in detail with reference to the accompanying drawings.

[0060] Here, the description of the contents described in the prior art and the overlapping contents will be omitted, and the description will focus on the newly added components in the present invention.

[0061] The first embodiment of the substrate temperature measuring device 200 according to the present invention will be described.

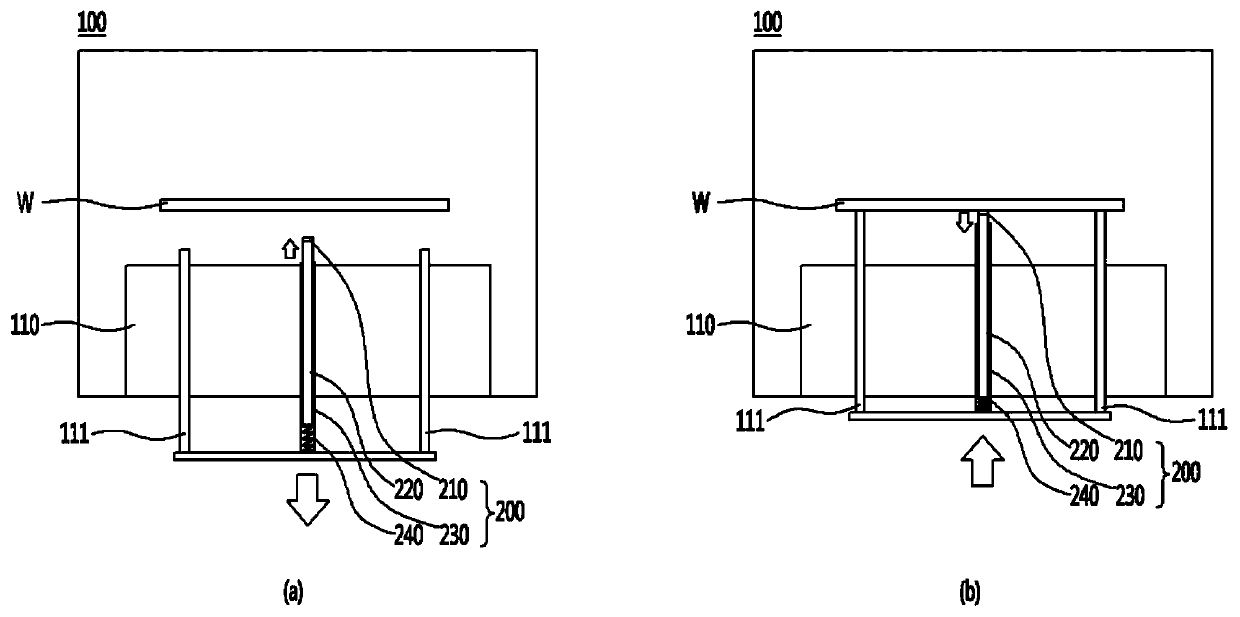

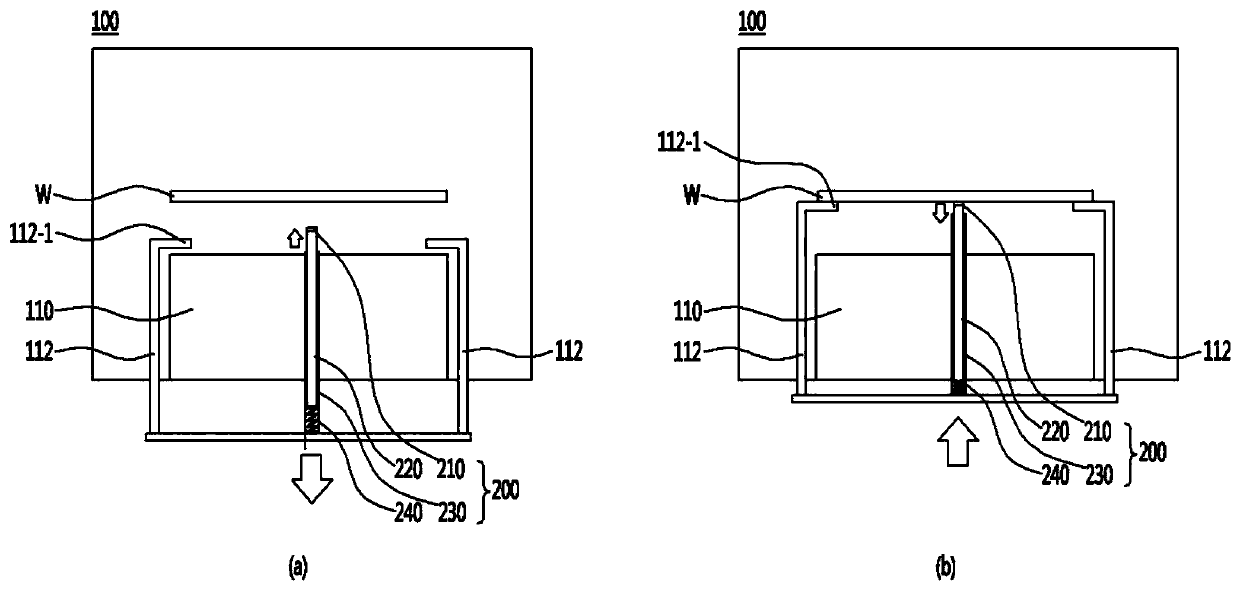

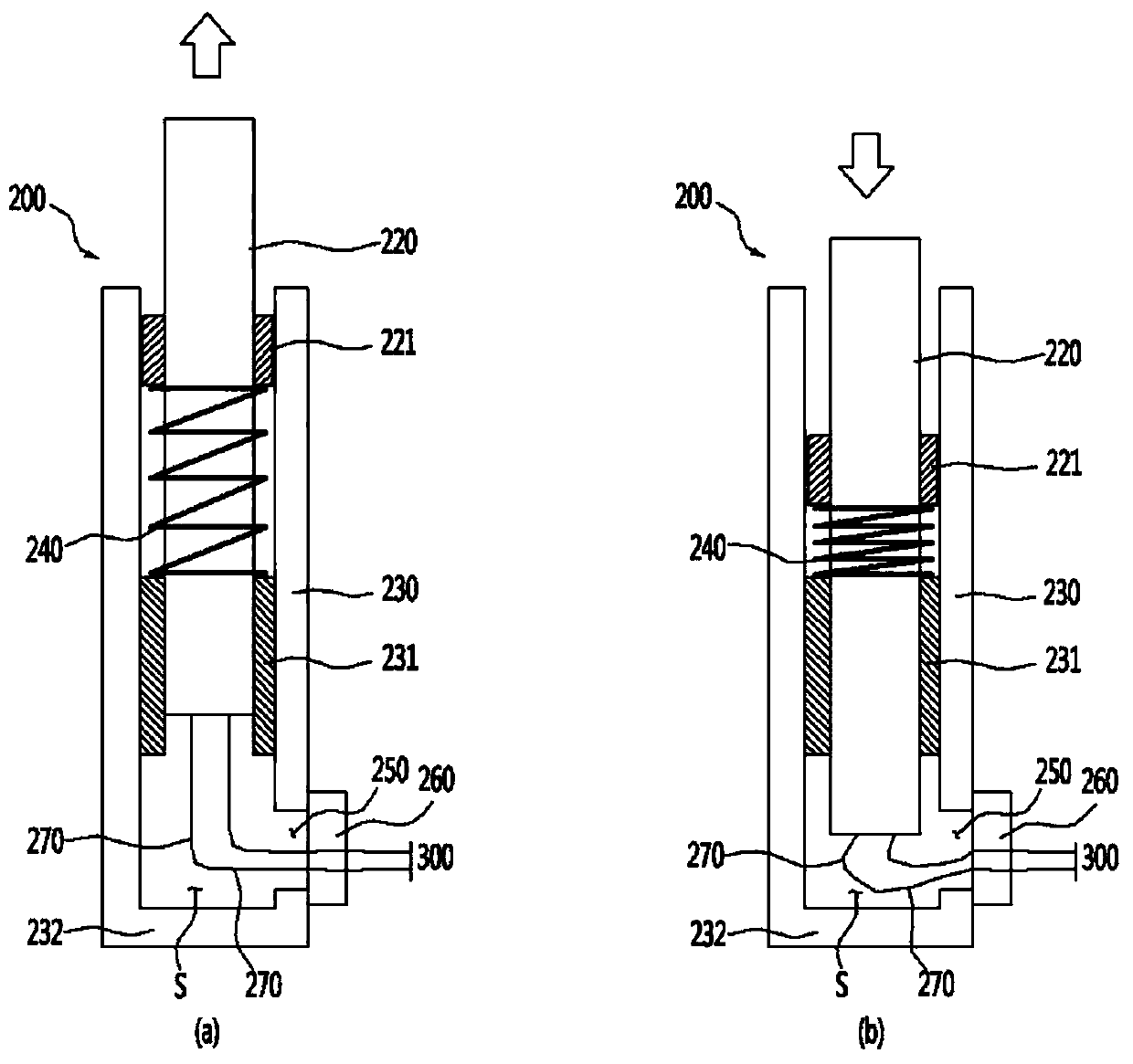

[0062] like figure 1 As shown, the substrate temperature measuring device 200 according to the present invention includes a probe 220, and is equipped to penetrate up and down the substrate support part 110 that supports the substrate W and performs the substrate processing process, and the upper end 210 of the substrate temperature measuring device 200 is lifted from the substrate support part. The upper surface of the probe 110 protrudes, wherein t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com