A method for purifying ammonium sulfate mother liquor produced by sintering flue gas ammonia desulfurization process

A technology for ammonium sulfate mother liquor and ammonia desulfurization, which is applied in chemical instruments and methods, separation methods, dispersed particle separation, etc. Long precipitation time and other problems, to achieve the effect of easy promotion, low cost and good purification effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

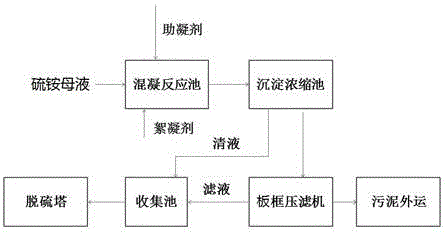

[0018] Add 10 cubic meters of original ammonium sulfate mother liquor produced by the ammonia desulfurization process in the coagulation reaction tank, heat up to 40 ° C, add 10 kg of polyaluminium chloride while stirring, and stir for 10 minutes at a stirring speed of 150 rpm. Then add the sulfite amide of 10kg, then stir for 20 minutes at a stirring speed of 60 rpm, stop stirring;

[0019] Then transfer to the precipitation concentration tank and let it stand for 2 hours. After fully stratified, the supernatant liquid, that is, the treated ammonium sulfate mother liquor, is collected in the collection tank, and the lower sediment is transferred to the plate and frame filter press. The filter press is used to filter, and the filtrate produced by the filtration, that is, the treated ammonium sulfate mother liquor, is collected into the collection pool, and the filtered filter residue is transported out through the sludge transport system. The treated ammonium sulfate mother li...

Embodiment 2

[0027] Add 10 cubic meters of original ammonium sulfate mother liquor (the same batch as the thiamine mother liquor used in the embodiment) produced by the ammonia desulfurization process in the coagulation reaction tank, and add 20kg of polymerized chlorine while stirring under room temperature conditions. Aluminum, stir to disperse, then add 10kg of activated silicic acid, stir to disperse, stop stirring;

[0028] Then transfer to the precipitation concentration tank and let it stand for 1 hour. After the system is fully stratified, the supernatant, that is, the treated ammonium sulfate mother liquor, is collected in the collection tank, and the lower sediment is transferred to the plate and frame filter press. The frame filter press is used for filtration, and the filtrate produced by the filtration, that is, the treated ammonium sulfate mother liquor, is collected into the collection pool, and the filtered residue is transported through the sludge transport system. The tre...

Embodiment 3

[0036] Add 10 cubic meters of original ammonium sulfate mother liquor in the coagulation reaction tank, add 15 kg of polyaluminum sulfate while stirring at 15 ° C, stir for 10 minutes at a stirring speed of 150 rpm, then add 15 kg of sodium alginate, and then Stir for 20 minutes at a stirring speed of 60 rpm, then stop stirring;

[0037] Then transfer to the precipitation concentration tank and let it stand for 0.5 hours. After the system is fully layered, the supernatant, that is, the treated ammonium sulfate mother liquor, is collected in the collection tank, and the lower sediment is transferred to the plate and frame filter press. The filter press is used to filter, and the filtrate produced by the filtration, that is, the treated ammonium sulfate mother liquor, is collected into the collection pool, and the filtered filter residue is transported out through the sludge transport system. The treated ammonium sulfate mother liquor in the collection pool can be transferred to...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com