Combined corner feeding chamber-type filter plate and liquid discharge method thereof

A combined type, filter plate technology, applied in separation methods, chemical instruments and methods, filtration and separation, etc., can solve the problems that the material filtration effect cannot be achieved, the filtration requirements cannot be met, and the moisture content of the filter cake is high, and the effective filtration can be increased. Area, good washing effect and low moisture content of filter cake

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

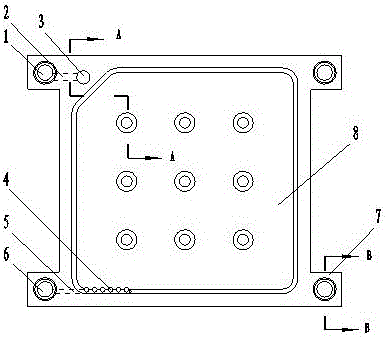

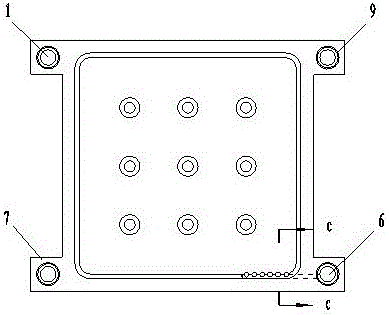

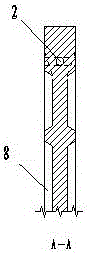

[0017] see figure 1 , figure 2 , image 3 , Figure 4 and Figure 5 As shown, the present invention provides a combined corner-feeding box-type filter plate and its liquid outlet method, which is implemented in the following manner. The material used for the manufacture of the combined corner-feeding box-type filter plate is polypropylene, the main board and accessories The plates are made by the same method, the material used is the same as polypropylene, and the structure of the filter plate is the same as a box-type filter plate. The outer dimension of the filter plate is made by using a mold, including the structure of the outer ear 7, and the filter chamber 8 and the support platform are made. It is made by the mold, and the corner feed channel 1 and the underflow hole 6 are made by the mold. The size of the mold should have machining allowance and shrinkage. The main board and the matching board mold are molded by a flat vulcanizer. Remove the burr from the blank of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com