Sewage lifting equipment

A sewage lifting and equipment technology, applied in waterway systems, water supply devices, drainage structures, etc., can solve the problems of incomplete sewage lifting and sewage lifting, and achieve the effects of reducing usage, saving energy, and reducing manufacturing costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The principles and features of the present invention are described below in conjunction with the accompanying drawings, and the examples given are only used to explain the present invention, and are not intended to limit the scope of the present invention.

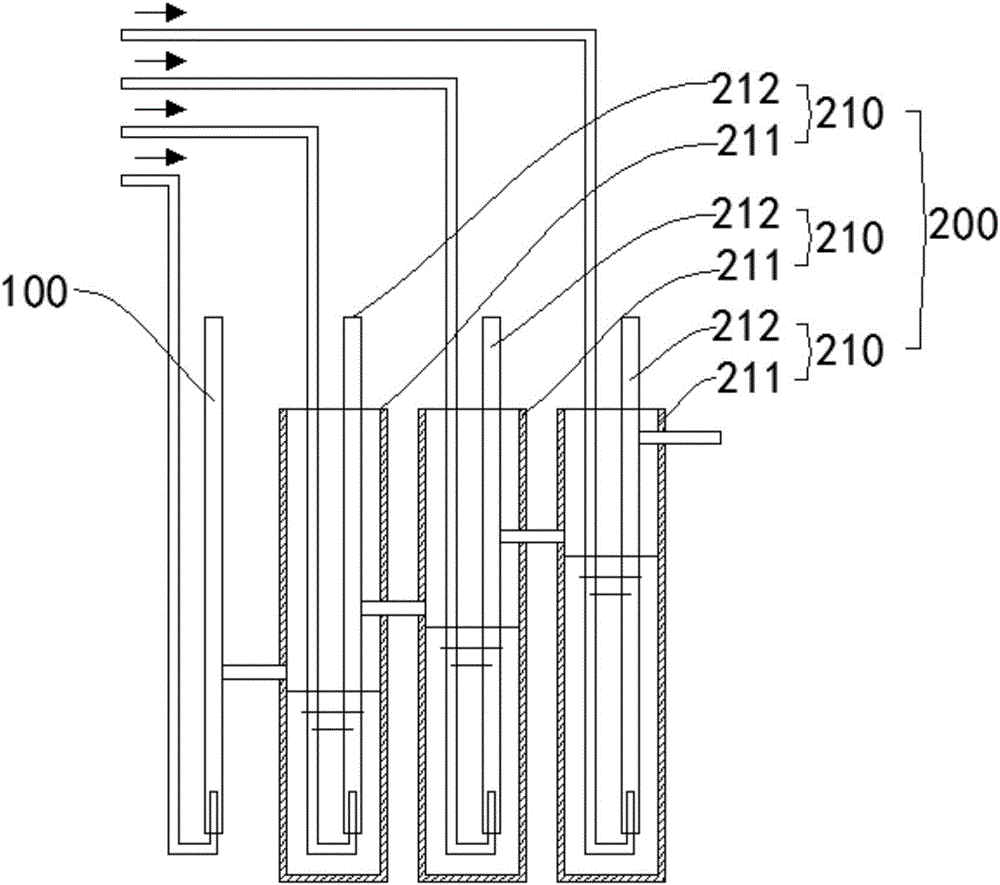

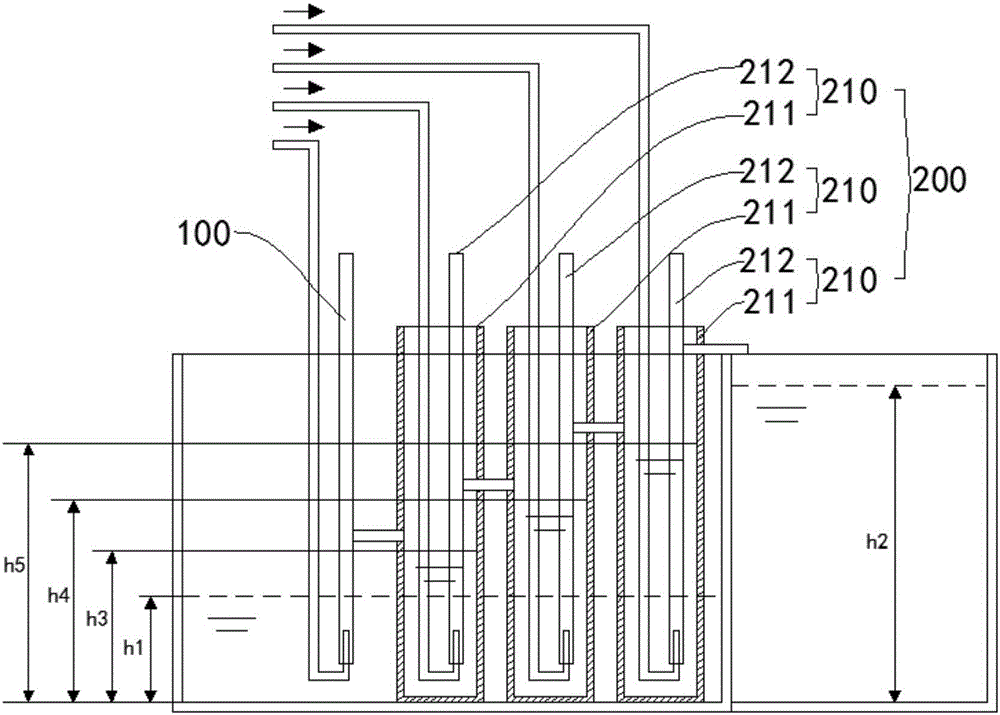

[0017] Such as figure 1 As shown, a sewage lifting device includes an air source, a first gas lift pipe 100 , and a sewage multi-stage lifting structure 200 for multi-stage lifting of the sewage output by the first gas lift pipe 100 . The gas source supplies gas to the first gas riser 100 .

[0018] The sewage multi-stage lifting structure 200 is composed of a plurality of single-stage sewage lifting parts 210; when setting, according to specific needs, the number of single-stage sewage lifting parts 210 can be one, two, three, four, five, six Wait a minute. All single-stage sewage lifting parts 210 are matched and connected in turn to form multi-stage lifting; each single-stage sewage lifting part 210 is composed...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com