Method for enhancing hydrophobic agglomeration of suspended clay mineral-fine-grained kaolinite in water body

A clay mineral and kaolinite technology, applied in the fields of metallurgy, beneficiation and environmental treatment, can solve the problems that the settlement effect cannot reach industrial application, the hydrophobicity is not strong enough, the hydrophobic agglomeration strength is not strong enough, etc., and the agglomeration and settlement effect is remarkable. , the effect of fast settling speed and large floc size

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

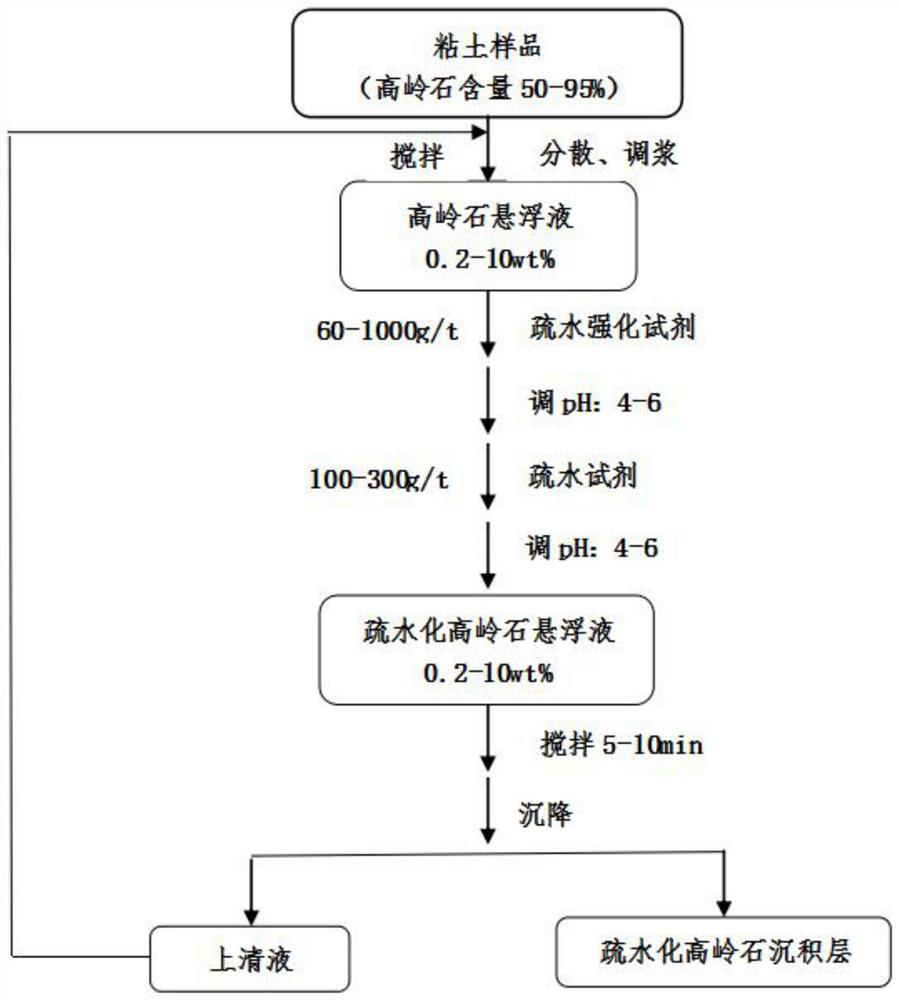

Method used

Image

Examples

Embodiment 1

[0025] (1) The clay mineral-kaolinite is dispersed into a suspension with tap water, and the mass percentage of the solid in the suspension is 5wt%. In the described clay mineral-kaolinite, about 90% of the kaolinite also contains a small amount of iron, titanium, Magnesium and calcium oxides and a small amount of organic matter; the particle size of kaolinite clay samples is <20 μm, of which 81% are smaller than 10 μm, and 15% are smaller than 2 μm.

[0026] (2) add valeric acid-KOH solution in the suspension that step (1) obtains by the ratio of 700g / t of valeric acid input concentration, then add KOH solution to adjust the pH of suspension to be 5.8, stir 10min under normal temperature, to The short-chain hydrophobization modification was carried out on the specific area of kaolinite surface.

[0027] (3) add the hydrochloric acid solution of dodecylamine (DDA) in the suspension that step (2) obtains in the ratio of 200g / t by dodecylamine (DDA) input concentration, keep t...

Embodiment 2

[0030] (1) Clay mineral-kaolinite is dispersed into a suspension with tap water, and the mass percentage of solid in the suspension is 10wt%. In the described clay mineral-kaolinite, about 90% of kaolinite also contains a small amount of iron, titanium, Magnesium and calcium oxides and a small amount of organic matter; the particle size of kaolinite clay samples is <20 μm, of which 81% are smaller than 10 μm, and 15% are smaller than 2 μm.

[0031] (2) put octanoic acid-NaOH solution in the suspension that step (1) obtains in the ratio of 700g / t by octanoic acid concentration, then add NaOH solution to adjust the pH of suspension to be 5.8, stir 10min under normal temperature, to kaolin Short-chain hydrophobization modification of specific regions on the stone surface.

[0032] (3) Add an acetic acid solution of dodecylamine (DDA) to the suspension obtained in step (2) at a ratio of 260g / t to keep the acidity of the suspension constant, and continue to stir for 10min to obtain...

Embodiment 3

[0035] (1) The clay mineral-kaolinite is dispersed into a suspension with tap water, and the mass percentage of solids in the suspension is 0.2wt%. In the described clay mineral-kaolinite, about 90% of the kaolinite also contains a small amount of iron and titanium , magnesium and calcium oxides and a small amount of organic matter; the particle size of kaolinite clay samples is less than 20 μm, of which the particle size is less than 10 μm, accounting for about 81%, and the particle size is less than 2 μm, accounting for 15%.

[0036](2) drop nonanoic acid-NaOH solution in the suspension that step (1) obtains by the ratio of 70g / t feeding concentration of nonanoic acid, then add NaOH solution to adjust the pH of suspension to be 5.5, stir 10min under normal temperature, to The short-chain hydrophobization modification was carried out on the specific area of kaolinite surface.

[0037] (3) add the acetic acid solution of dodecylamine (DDA) in the suspension that step (2) obt...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com