Pipe piece used for shield construction and process for assembling pipe piece into ring

A segment and shield technology, which is applied in shaft equipment, shaft lining, tunnel lining, etc., can solve the problems of shortened working hours, influence on the overall process of shield construction, and affect the efficiency of shield construction, so as to reduce the work intensity , Increase the effect of a single working hour

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

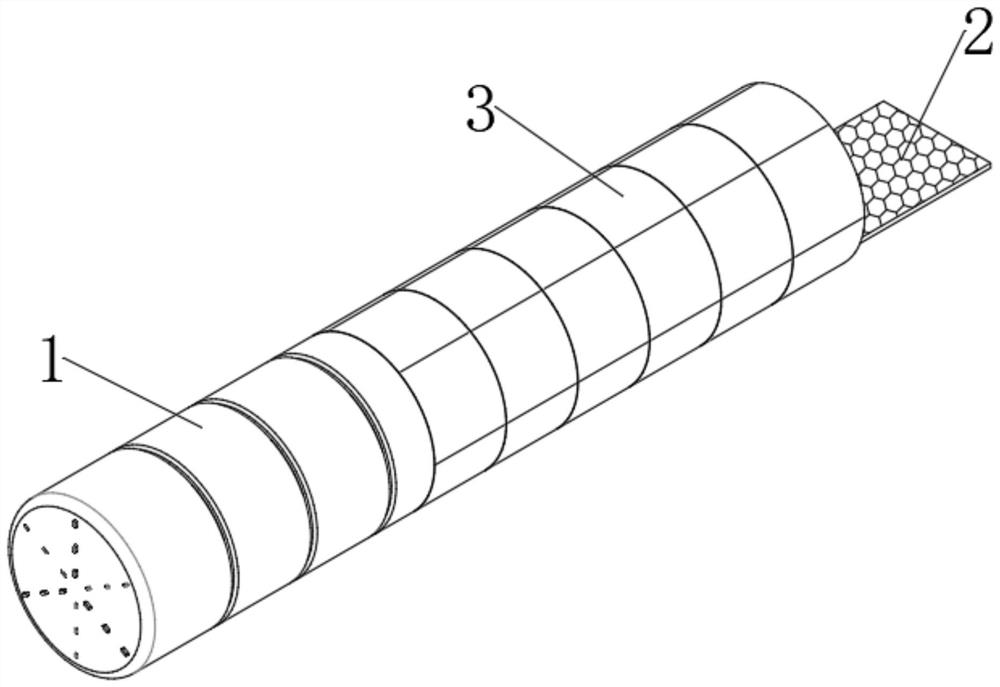

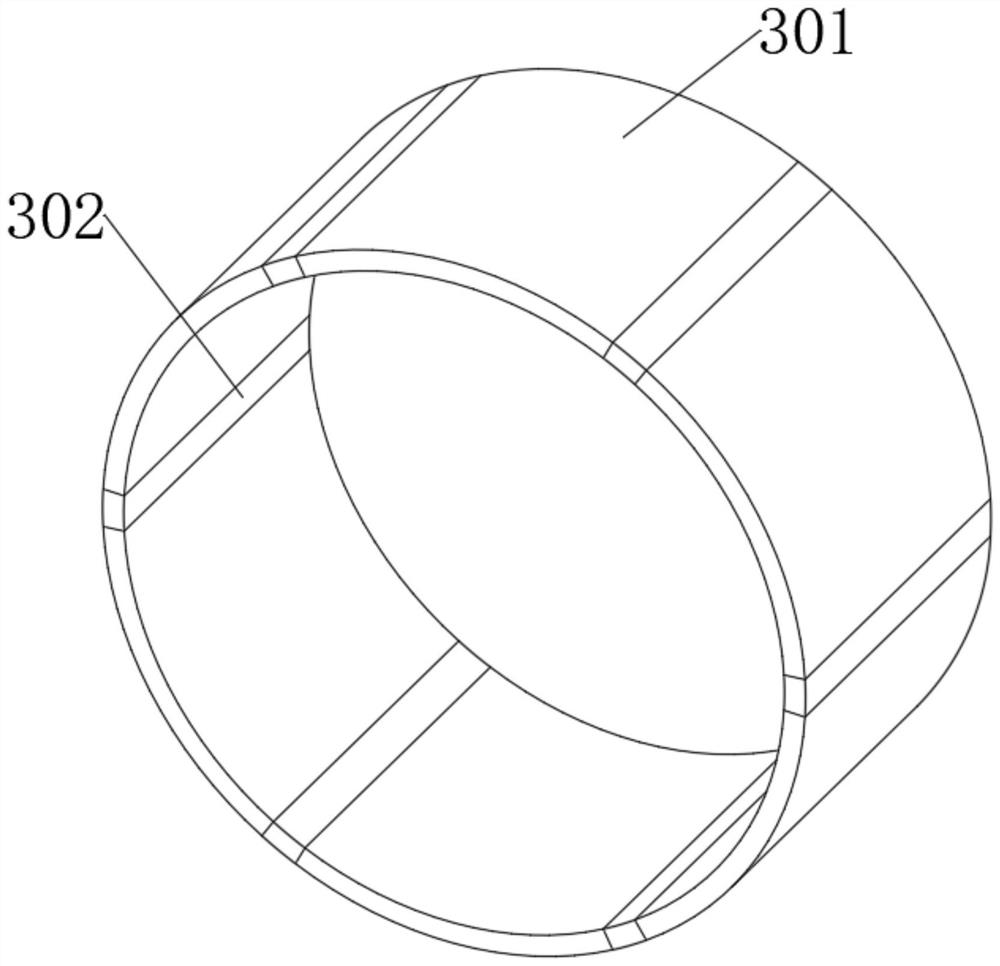

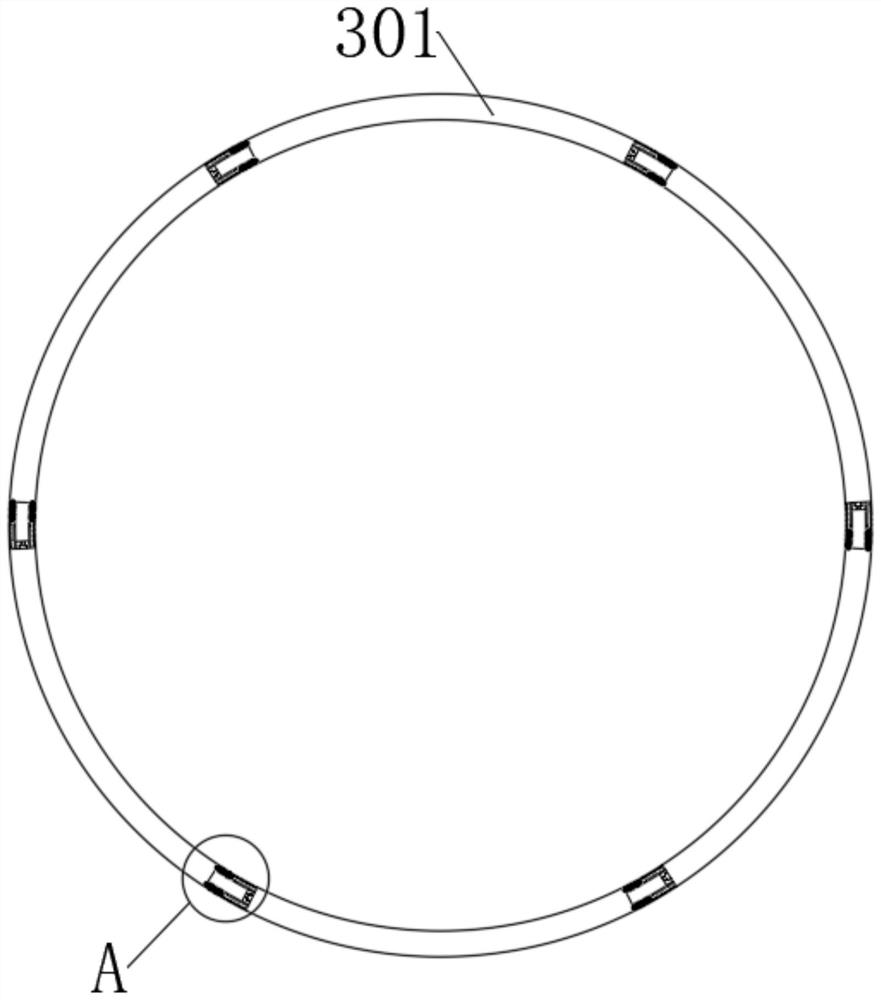

[0044] see Figure 1-8 , a segment for shield construction, including a segment 3, the segment 3 includes a matching concrete plate 301 and an elastic gasket 302, six segments 3 form a complete set of segment rings, and a set of concrete The plate 301 is fixedly connected to the elastic gasket 302, and the six groups of concrete panels 301 and the elastic gasket 302 are connected end to end to form a ring shape. cavity 11, the opening of the positioning cavity 11 away from the end of the concrete slab 301 is fixedly connected with a sealing diaphragm 14 matching itself, the positioning cavity 11 is filled with ceramic adhesive, the filling cavity 5 is filled with liquid water, and the concrete slab 301 One end away from the elastic gasket 302 is fixedly connected with a plurality of positioning blocks 10 matching the positioning cavity 11, and two adjacent concrete slabs 301 are positioned through the cooperation between the positioning cavity 11 on the elastic gasket 302 and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com