Method and device for recycling iodine from cooling water in first cooling tower used in yellow phosphorus production and used cooling tower

A cooling tower and cooling water technology, applied in the direction of iodine, iodine/hydrogen iodide, etc., can solve the problems of resource waste, environmental pollution, low blowing efficiency, etc., and achieve the goal of improving recovery rate, reducing environmental pollution rate, and reducing emissions Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

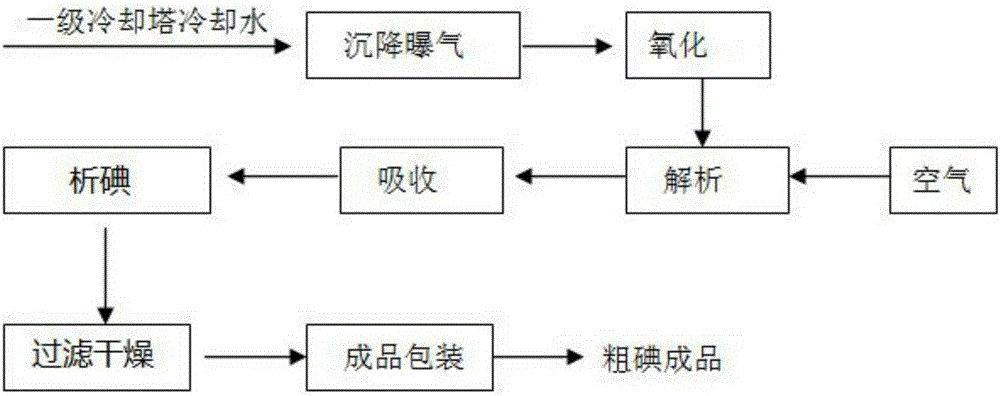

[0030] like figure 1 As shown, a method for recovering yellow phosphorus to produce iodine in the cooling water of the first-stage cooling tower, transfers the cooling water of the first-stage cooling tower to the settling tank for sedimentation treatment, and then overflows the supernatant to the oxidation tank, and add oxidant to the oxidation tank, And use a stirrer to stir for 2.5h, Then the liquid is pumped into the analysis tank with a slurry pump, and air is introduced from the air separation equipment for analysis treatment, and the iodine-containing gas enters the absorption tower, and is circulated and absorbed by the reducing agent until the concentration of iodine in the solution reaches After ≥600ppm, it is subjected to iodine analysis to obtain elemental iodine, and the elemental iodine is put into a drying device for drying and packaging to obtain the finished crude iodine. Described oxidizing agent is chlorine gas. The reducing agent is an aqueous solution ...

Embodiment 2

[0032] like figure 1 As shown, a method for recovering yellow phosphorus to produce iodine in the cooling water of the first-stage cooling tower, transfers the cooling water of the first-stage cooling tower to the settling tank for sedimentation treatment, and then overflows the supernatant to the oxidation tank, and add oxidant to the oxidation tank, And use a stirrer to stir for 2h, Then the liquid is pumped into the analysis tank with a slurry pump, and air is introduced from the air separation equipment for analysis treatment, and the iodine-containing gas enters the absorption tower, and is circulated and absorbed by the reducing agent until the concentration of iodine in the solution reaches After ≥600ppm, it is subjected to iodine analysis to obtain elemental iodine, and the elemental iodine is put into a drying device for drying and packaging to obtain the finished crude iodine. Described oxidizing agent is chlorine, sodium hypochlorite mixture. The reducing agent ...

Embodiment 3

[0034] like figure 1 As shown, a method for recovering yellow phosphorus to produce iodine in the cooling water of the first-stage cooling tower, transfers the cooling water of the first-stage cooling tower to the settling tank for sedimentation treatment, and then overflows the supernatant to the oxidation tank, and add oxidant to the oxidation tank, and use a stirrer to stir for 3h,Then the liquid is pumped into the analysis tank with a slurry pump, and air is introduced from the air separation equipment for analysis treatment, and the iodine-containing gas enters the absorption tower, and is circulated and absorbed by the reducing agent until the concentration of iodine in the solution reaches After ≥600ppm, it is subjected to iodine analysis to obtain elemental iodine, and the elemental iodine is put into a drying device for drying and packaging to obtain the finished crude iodine. Described oxidant is chlorine, sodium hypochlorite, hydrogen peroxide. The reducing agen...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com