Eddy current detecting device of seamless steel tubes

A technology for eddy current testing and seamless steel pipes, which is used in measuring devices, instruments, and material analysis by electromagnetic means. rate effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The structure of the present invention will be described in further detail below in conjunction with the accompanying drawings and specific embodiments, and the parts in the present invention that are the same as those of the prior art will be referred to the prior art.

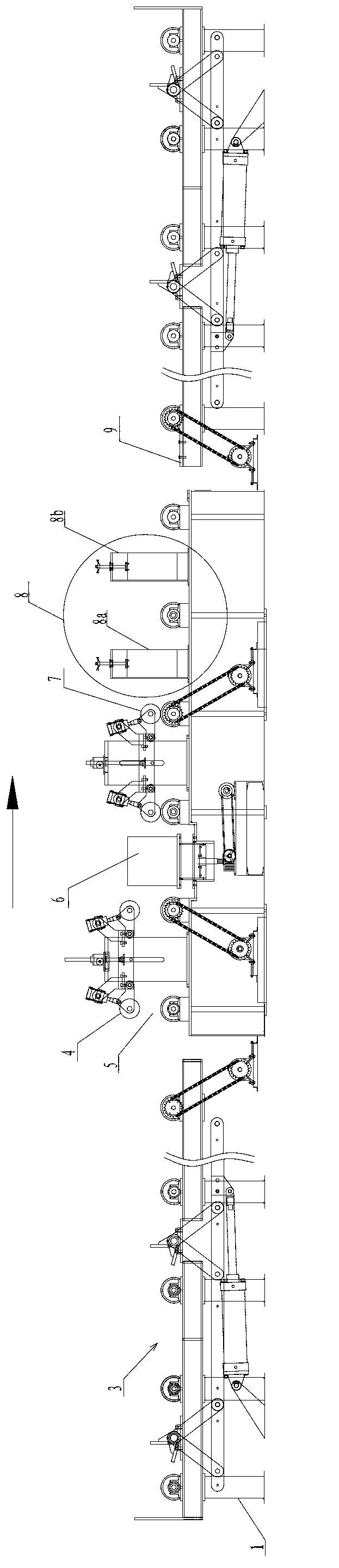

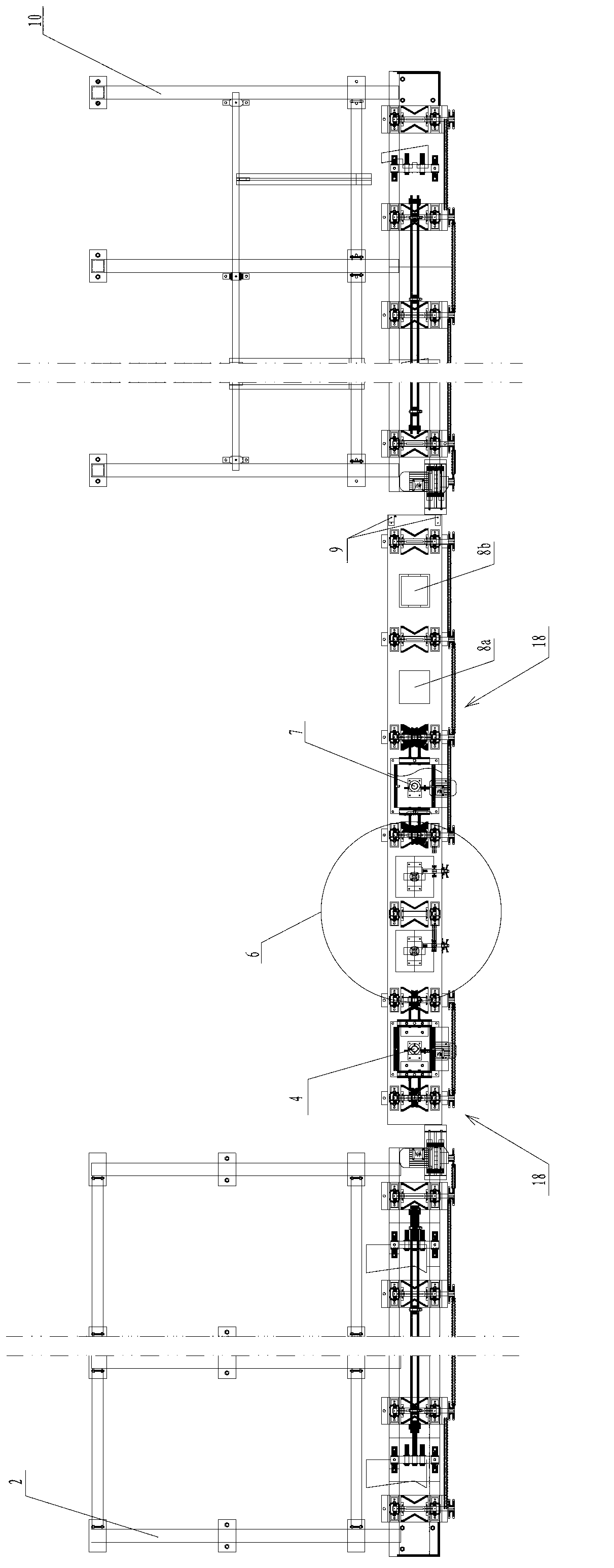

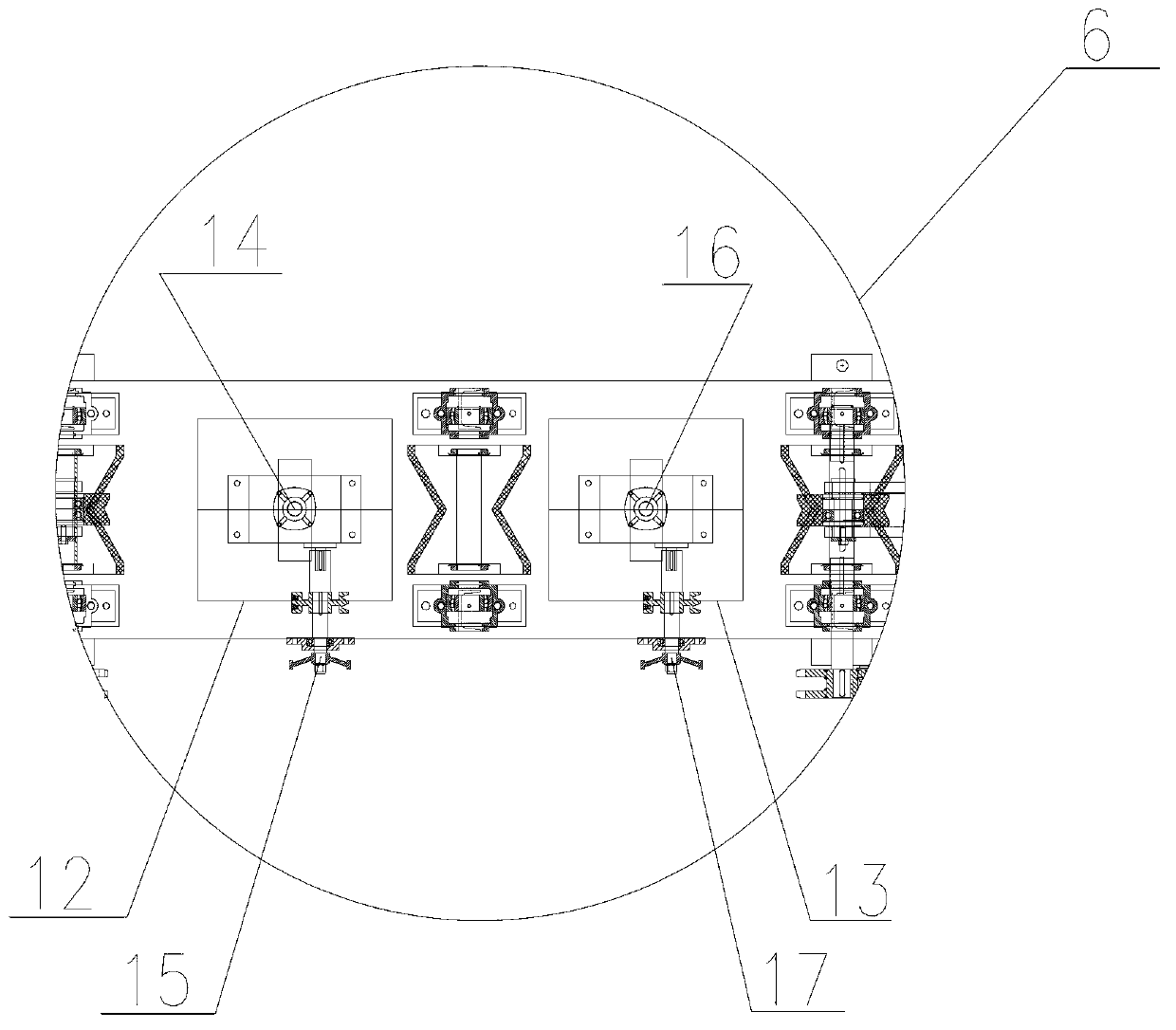

[0022] Such as Figure 1-4 As shown, the seamless steel pipe eddy current detection device includes a loading table 2, a conveying roller table 3, a feeding roller 4, a flaw detection roller table 5, an eddy current flaw detection device 6, and a blanking roller 7 installed on the frame 1 in sequence. , demagnetization device 8, marking seat 9 and blanking table 10, also includes an electric control device for controlling loading and unloading, steel pipe transmission, sorting, defect alarm, eddy current flaw detection device 6 includes high frequency flaw detection device 12 and The low-frequency flaw detection device 13, the high-frequency flaw detection device 12 and the low-frequency flaw detection...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com