A lithium-air battery mold

An air battery and mold technology, applied in the direction of fuel cell half-cells and primary battery-type half-cells, can solve the problems of complex components, poor battery space utilization, cumbersome assembly/disassembly process, etc., to achieve simple components, High space utilization and the effect of improving space utilization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

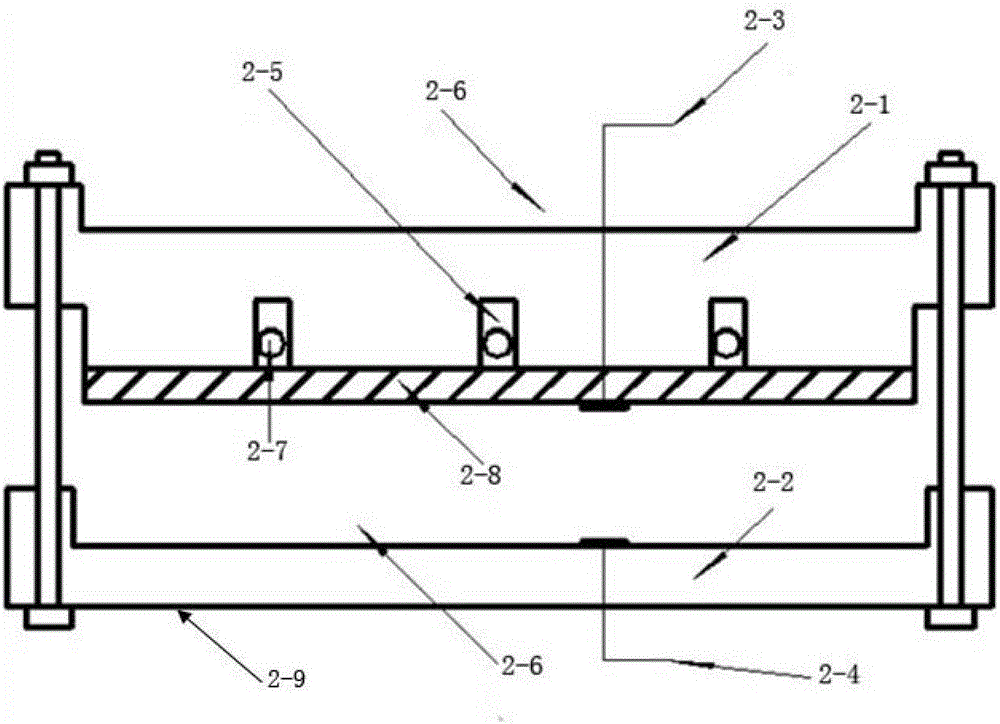

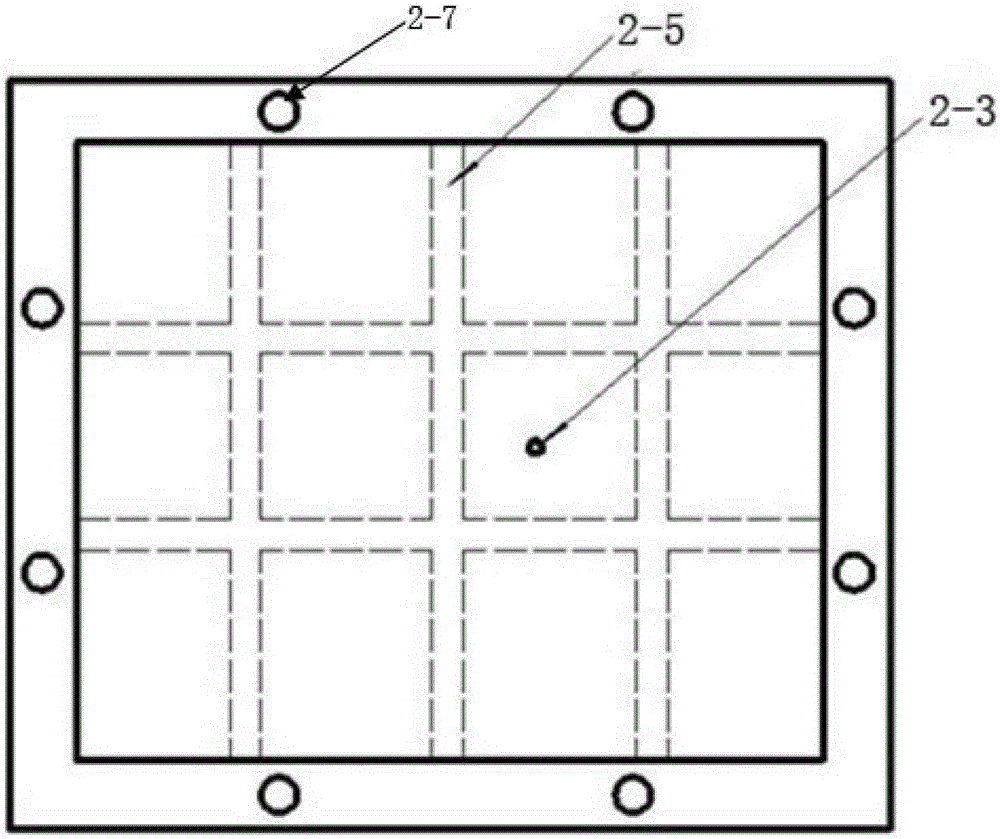

[0040] The assembly shell 2-1 and the base shell 2-2 are made of polytetrafluoroethylene, and the size is 100×100mm 2 .

[0041] The assembly process of the lithium-air battery is completed in the glove box. The process is as follows: the negative electrode of the lithium sheet is placed in the groove 2-6 on the base shell 2-2, the diaphragm is placed on the negative electrode of the lithium sheet, and an appropriate amount of electrolytic solution is dripped on the diaphragm. solution, place the air positive electrode on the diaphragm dripped with electrolyte, drop an appropriate amount of electrolyte on the air positive electrode, place a current collector on the air positive electrode dripped with electrolyte, then put it into the assembly shell 2-1, and finally pass the rotating Tighten the bolts to secure the battery case. Place the assembled cells in an air or oxygen atmosphere, and connect the test circuit to test the performance of the cells. Place the assembled cell...

Embodiment 2

[0044] The two assembled shells 2-1 and the base shell 2-2 are made of polypropylene material, and the area of the assembled shell 2-1 and the base shell 2-2 is 100×200mm 2 . Brass materials are used as the positive electrode lead 2-3 and the negative electrode lead 2-4.

[0045]The assembly process of the lithium-air secondary battery pack is completed in the glove box, the negative electrode of the lithium sheet is placed in the groove 2-6 on the base shell 2-2, the diaphragm is placed on the negative electrode of the lithium sheet, and an appropriate amount of electrolyte is dripped on the diaphragm, Place the air positive electrode on the diaphragm dripped with electrolyte, drop an appropriate amount of electrolyte on the air positive electrode, place a current collector on the air positive electrode dripped with electrolyte, and then put it into the assembly case 2-1, and then put another lithium The negative electrode of the lithium sheet is placed in the groove 2-6 o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com