Chemical process automation comprehensive training device

A training device and automation technology, applied in the direction of educational appliances, instruments, teaching models, etc., can solve the problems of difficult to meet the teaching requirements, increased investment in equipment funds, and inability to carry out multiple control technologies and equipment at the same time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] The present invention will be specifically introduced below in conjunction with the accompanying drawings and specific embodiments.

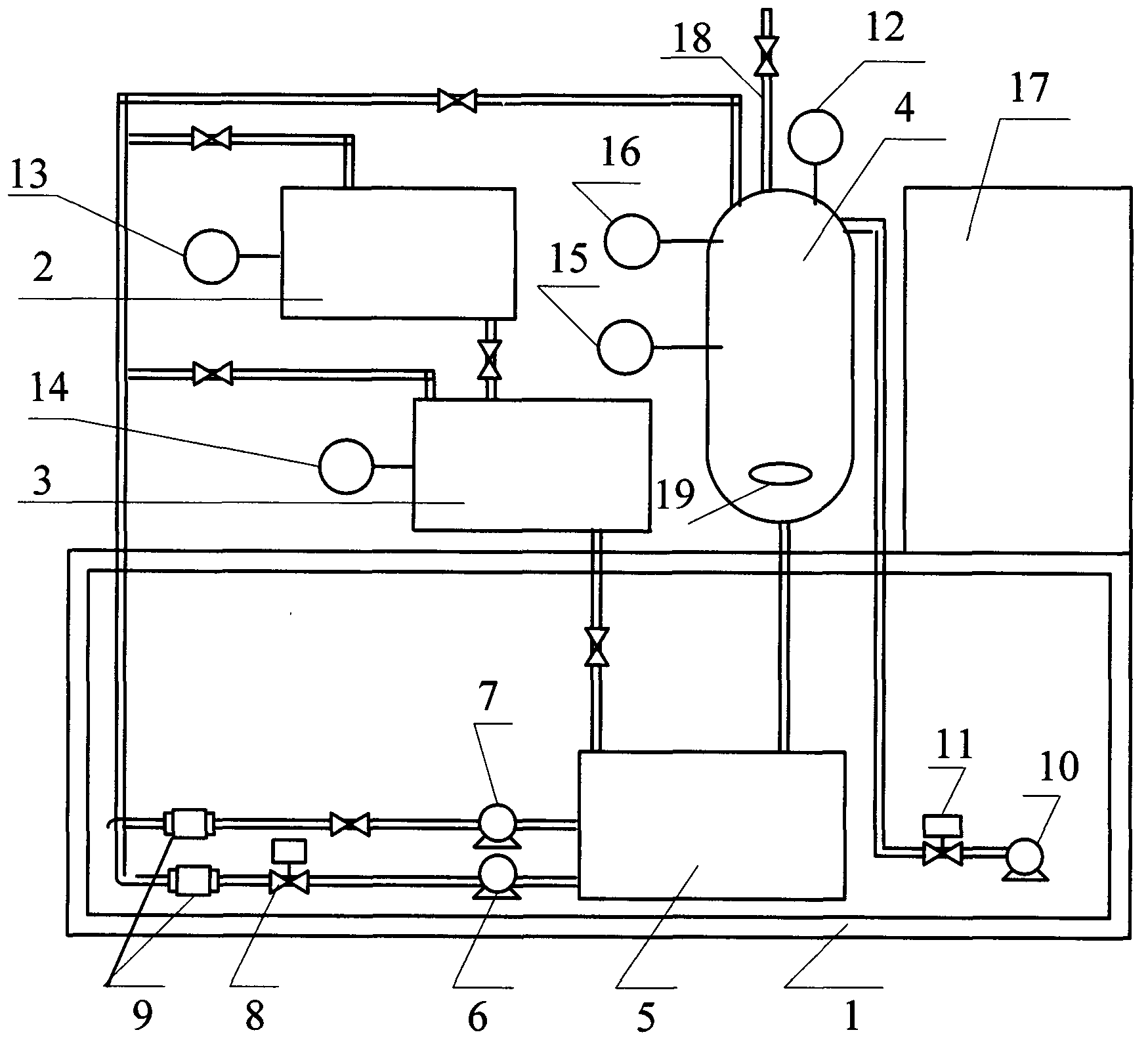

[0014] Such as figure 1 Shown: chemical automation comprehensive training device, including frame 1, control cabinet 17, simulated object system, described simulated object system, includes upper water tank 2, lower water tank 3 and hot water boiler 4 positioned at the upper part of frame 1, and setting The water storage tank 5 and the air compressor 10 at the lower part of the frame 1, wherein the upper water tank 2, the lower water tank 3 and the hot water boiler 4 are all communicated with the water storage tank 5 through two identical pipelines, and the two A first magnetic circulation pump 6 and a second magnetic circulation pump 7 are respectively arranged on the pipeline, and the hot water boiler 4 communicates with the air compressor 10 .

[0015] In this embodiment, the first electric actuator 8 is also arranged on the pipeline ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com