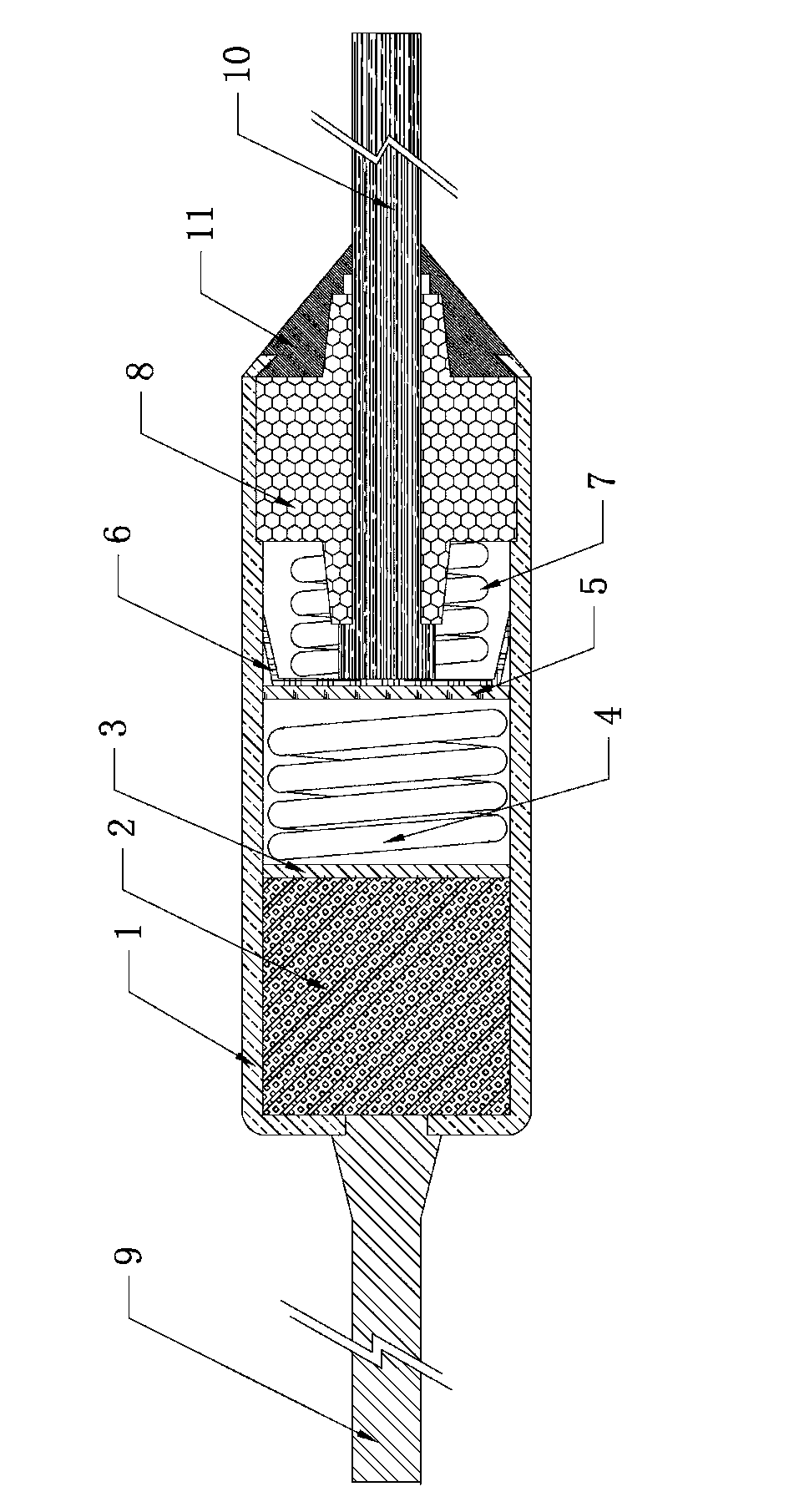

Thermal link for electric cooker

A thermal fuse and rice cooker technology, which is applied to thermal switch components, heating/cooling contact switches, etc., can solve problems such as failure to meet the requirements of rice cookers

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

[0012] Example 1. Mix 0.55 Kg of p-methoxybenzoic acid, 0.3 Kg of adipic acid and 0.15 Kg of mannitol, and then directly press it into 1.5mm granules with a granulator; the thermal fuse for a finished rice cooker containing the granules The melting temperature is 168.1°C.

example 2

[0013] Example 2. After mixing 0.45Kg p-methoxybenzoic acid, 0.35Kg adipic acid and 0.2Kg mannitol, use a granulator to directly press them into 1.5mm granules; The melting temperature is 167.8°C.

example 3

[0014] Example 3. Mix 0.5 Kg of p-methoxybenzoic acid, 0.3 Kg of adipic acid and 0.2 Kg of mannitol, and then directly press it into 1.5mm granules with a granulator; the thermal fuse for the finished rice cooker containing the granules The melting temperature is 167.9°C.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com