Reclosing mechanism of residual-current circuit breaker

A leakage circuit breaker and reclosing technology, applied in the direction of protection switch operation/release mechanism, etc., can solve the problems of inability to install the whole circuit breaker, increase the size of the circuit breaker, increase the production cost, etc., so as to improve the service life, improve the production efficiency, The effect of reducing the difficulty of installation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

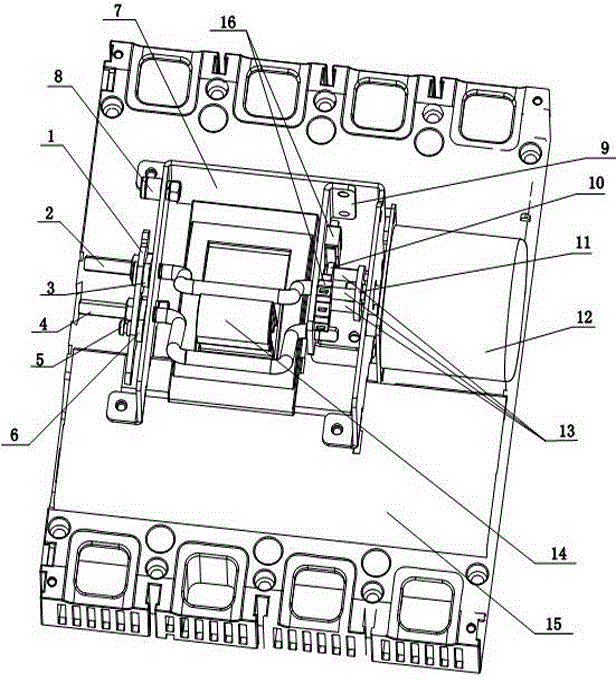

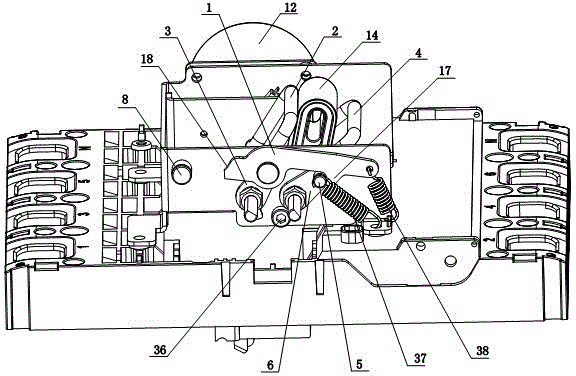

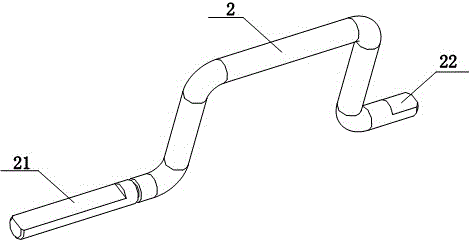

[0024] Such as figure 1 with figure 2 As shown, the present invention includes an outer frame 7, an inner bracket 9, a connecting rod, a turntable, two handle drivers, etc., and the outer frame 7 is fixedly mounted on a circuit breaker cover 15 with a handle 14, and the handle 14 extends out of the circuit breaker Outside the cover 15, the handle 14 can be rotated towards the wire inlet or outlet of the circuit breaker. The handle 14 is located between the two handle drive parts, and the two handle drive parts are respectively located at the wire-in end and the wire-out end side of the handle 14, that is, the first handle drive part 2 can be located at the wire-in end side of the handle 14, and the second handle drive The piece 4 can be located at the outlet end side of the handle 14 . The inner bracket 9 is fixedly installed in the outer frame 7 . The first turntable 10 is rotatably connected to the inner bracket 9, and the rotation direction of the first turntable 10 is ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com