A kind of graphite electronic heat dissipation material and its preparation method and application

A heat-dissipating material and graphite technology are applied in the fields of graphite electronic heat-dissipating material and its preparation and application, which can solve problems such as low thermal conductivity, and achieve the effect of improving the thermal conductivity index and avoiding wrinkles.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

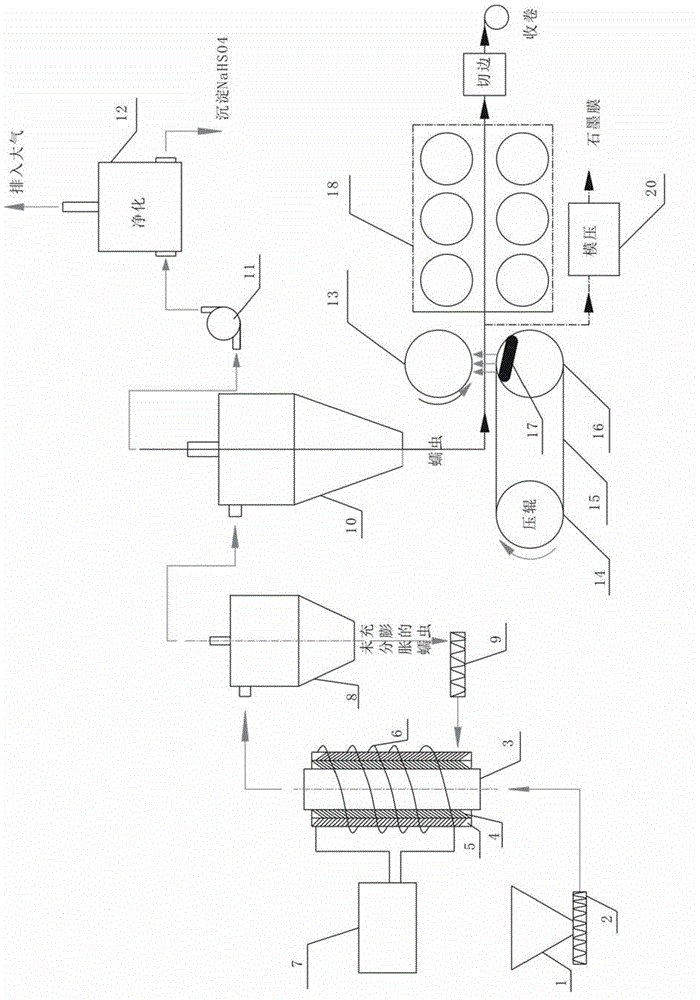

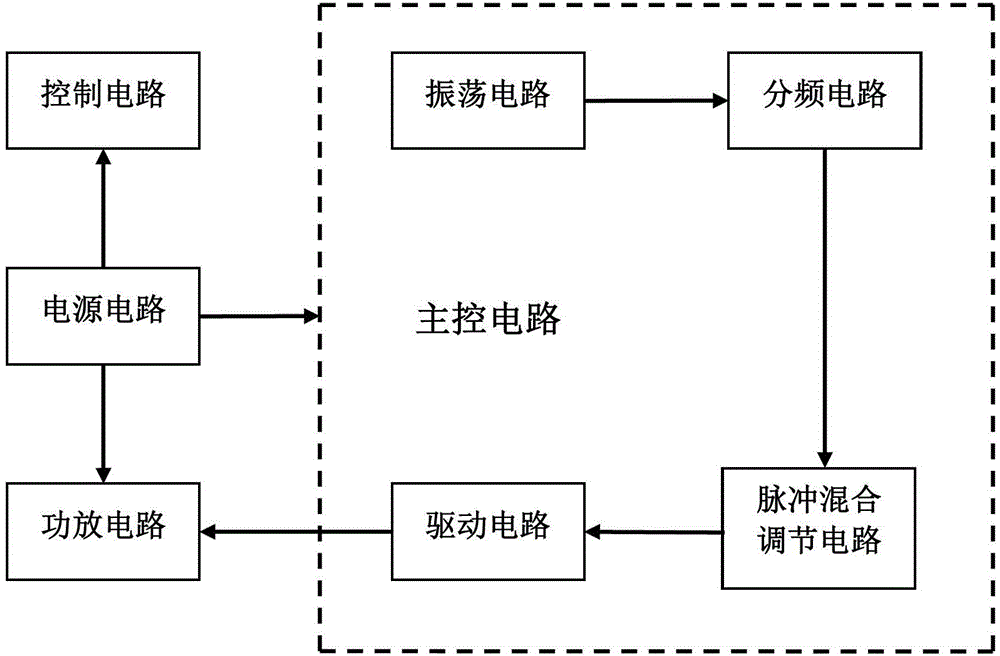

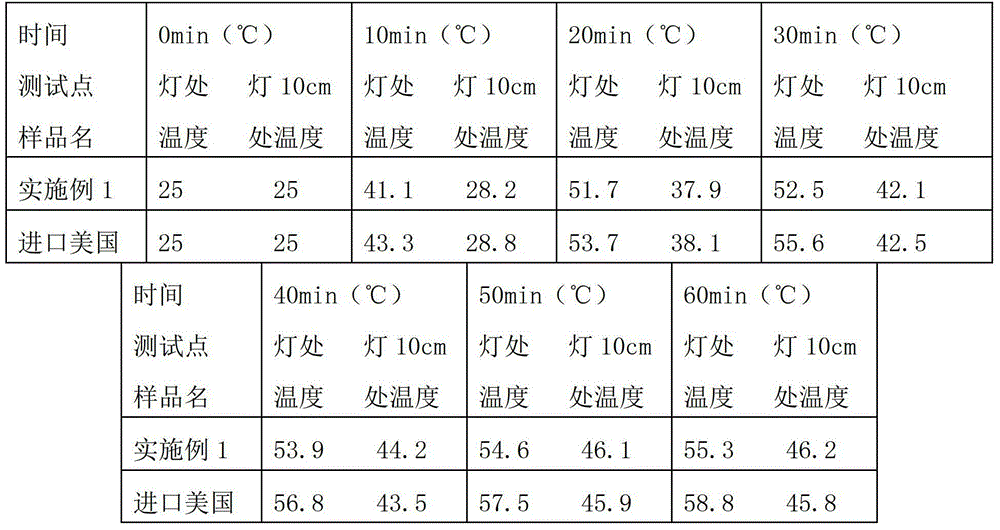

[0036] First, put +50 mesh expandable graphite with an expansion rate of 280ml / g into the raw material bin 1, and then send it into the expansion furnace body 3 from the lower part of the furnace body by the screw conveyor 2 under negative pressure, and the expansion furnace body 3 (Φ150mm) is a cylinder body and is made of carbon material, using a pulsed high-frequency (3-30MHZ) electric induction heating source 7, during which due to the internal eddy current of the expandable graphite, the temperature is instantly raised to 1000-1250°C and expands along the direction perpendicular to the layer of the expandable graphite. Graphite worms, the worms with sufficient expansion are separated from the solid and gas by the first-stage cyclone solid-gas separator 8, and then enter the second-stage solid-gas separator 10 from the top together with the airflow for further solid-gas separation. The diameter is much larger than the diameter of the first-stage cyclone solid-gas separator,...

Embodiment 2

[0038] First, put +80 mesh expandable graphite with an expansion ratio of 300ml / g into the raw material bin 1, and then send it into the expansion furnace body 3 from the lower part of the furnace body by the screw conveyor 2 under negative pressure, and the expansion furnace body 3 (Φ200mm) is a cylinder body and is made of carbon material, using a pulsed high-frequency (300-3000KHZ) electric induction heating source 7, during which due to the internal eddy current of the expandable graphite, the temperature is instantaneously raised to 1000-1250°C and expands along the direction perpendicular to the layer of the expandable graphite. Graphite worms, the worms with sufficient expansion are separated from the solid and gas by the first-stage cyclone solid-gas separator 8, and then enter the second-stage cyclone solid-gas separator 10 from the top together with the airflow for further solid-gas separation. The diameter of the separator is much larger than the diameter of the firs...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com