An electrically heated smoking system comprising at least two units

An electric heating and preheating technology, applied in the direction of electric/magnetic/electromagnetic heating, electric heating device, electrochemical generator, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

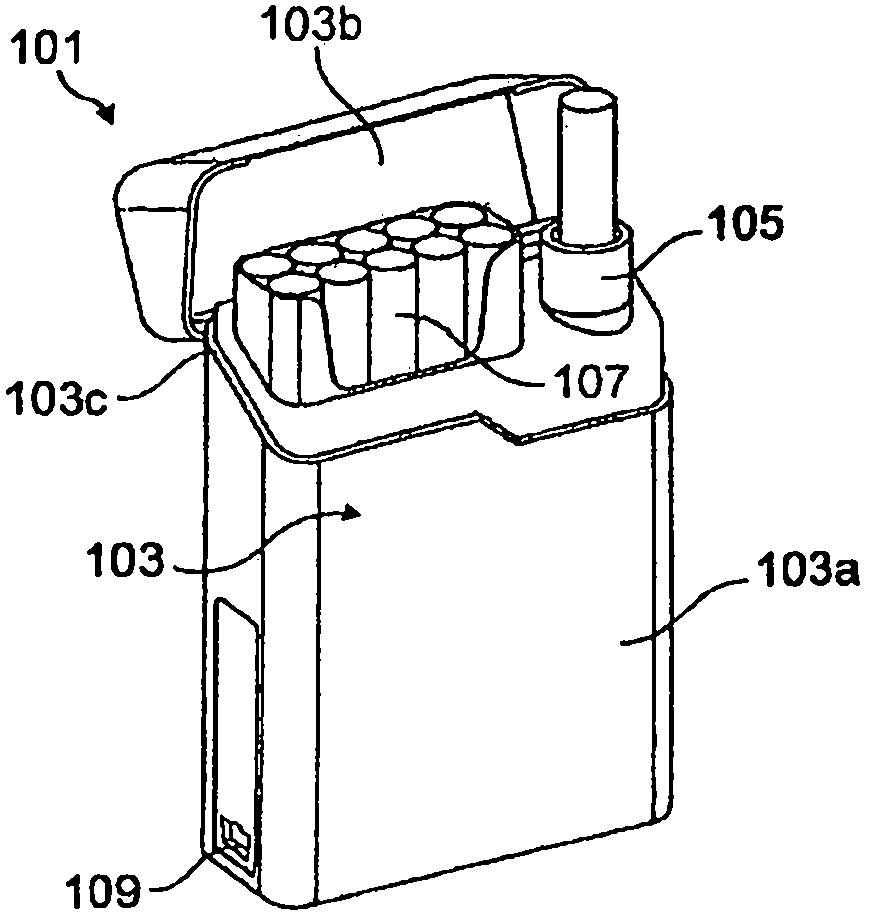

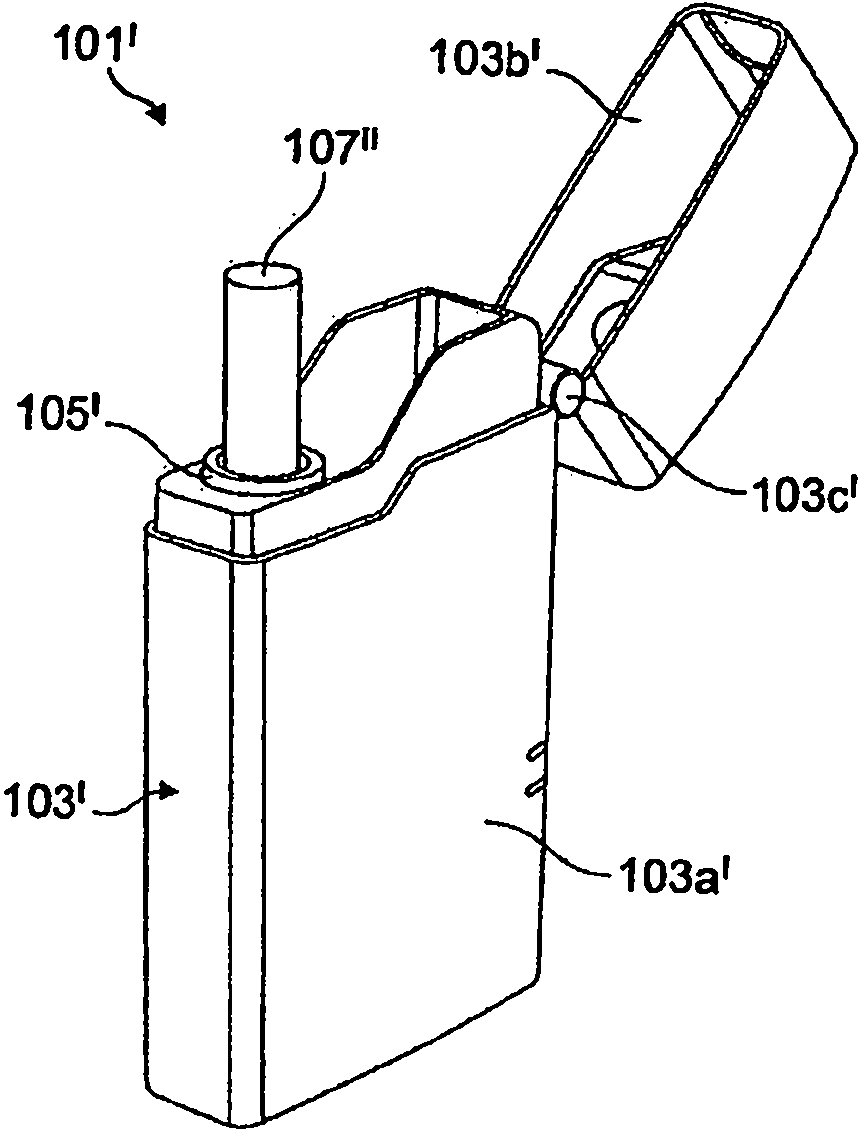

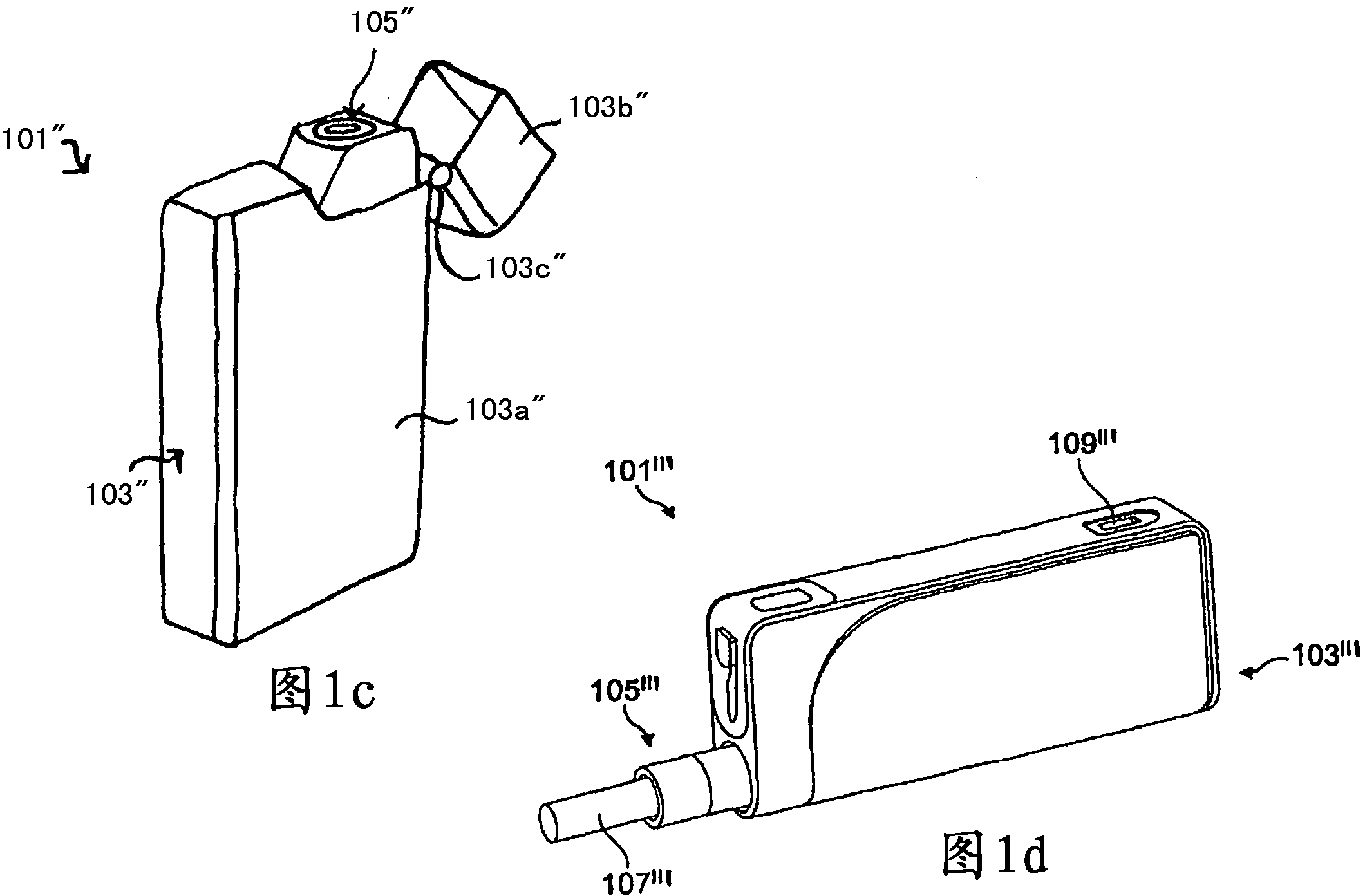

[0046]Typically, the invention does not require a primary unit, in which case the secondary unit may be a self-contained unit connectable to an existing external power supply. However, as noted above, in one embodiment the electrically heated smoking system of the present invention comprises a primary unit and one or more secondary units capable of receiving smoking articles. The main unit includes the main power supply and electronic circuits. The secondary unit includes a secondary power supply, electronic circuitry and at least one heating element. In charging mode, the primary power source in the primary unit is used to charge the secondary power source in the secondary unit. In the preheating mode, a secondary power supply in the secondary unit is used to raise the temperature of the aerosol-forming substrate to the operating temperature, and in the smoking mode, to maintain the substrate temperature during puffing. The required operating temperature will depend on the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com