Thumb structure of prosthetic hand

A prosthetic hand and thumb technology, applied in prosthesis, medical science, etc., can solve the problems of heavy weight, insufficient flexibility, too many drives, etc., and achieve the effect of strong self-adaptive ability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

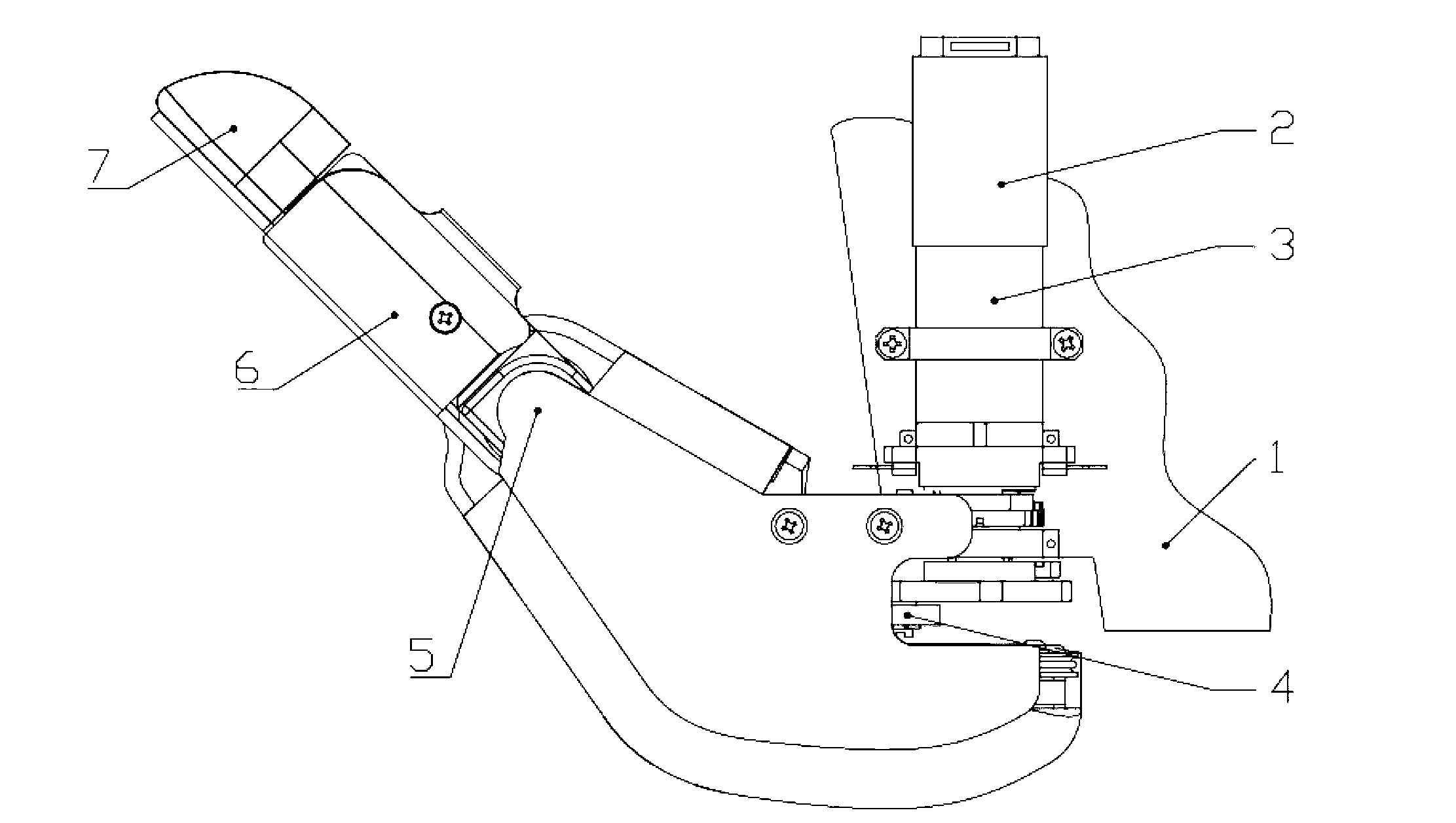

[0028] Such as figure 1 As shown, the present embodiment includes a palm base plate 1, a servo motor 2, a speed reducer 3, a transmission mechanism 4, a near knuckle 5, a middle knuckle 6 and a far knuckle 7; the servo motor 2 and the speed reducer 3 are fixed on the palm base plate 1, the servo motor 2 is connected to the reducer 3, the reducer 3 is connected to the transmission mechanism 4, the transmission mechanism 4 is connected to the proximal knuckle 5, and the proximal knuckle 5, middle knuckle 6 and distal knuckle 7 are connected in turn in rotation.

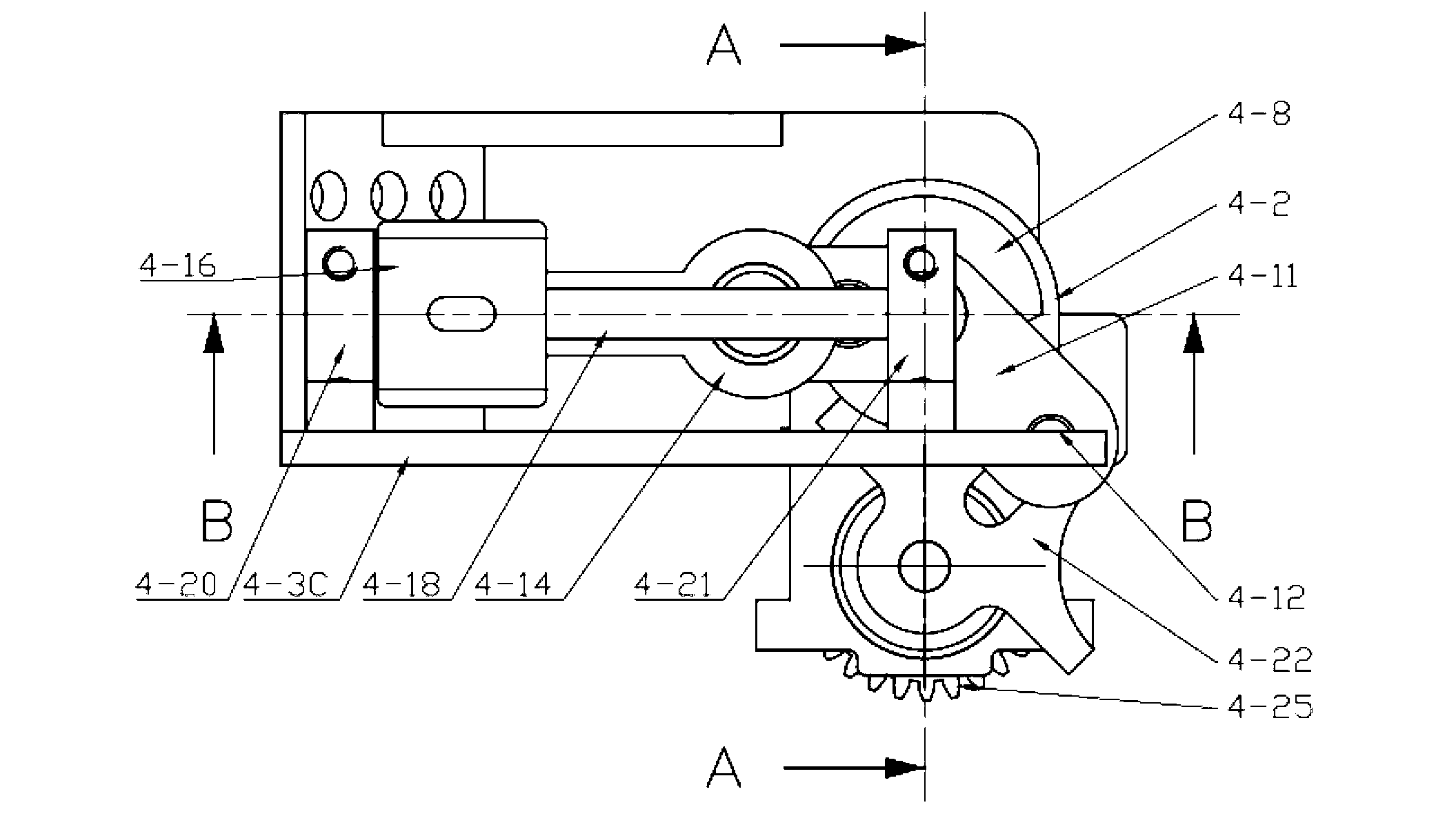

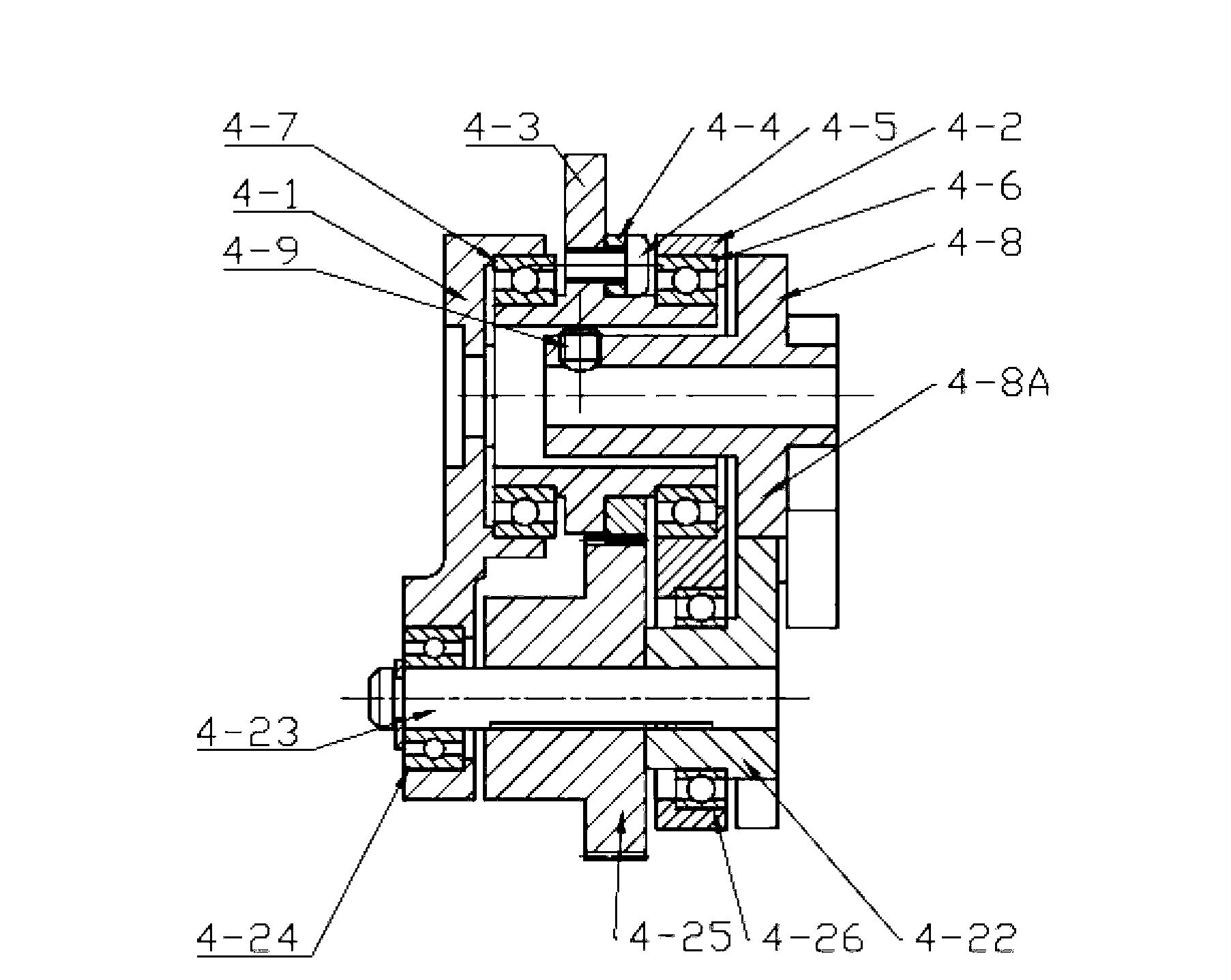

[0029] Such as figure 2 , image 3 , Figure 4 As shown, the transmission mechanism 4 includes a motor support plate 4-1, a sheave support plate 4-2, a thumb base 4-3, a driven gear 4-4, a round head screw 4-5, a first ball roller Sub-bearing 4-6, second ball roller bearing 4-7, driving dial...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com