Five-surface interference-free machining clamp and mounting method

A non-interference and clamping technology, which is applied in the direction of metal processing equipment, metal processing machinery parts, clamping, etc., can solve the problems of affecting the processing effect of process holes, the influence of process holes, and the inability to adapt to uniform clamping of parts of different sizes, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

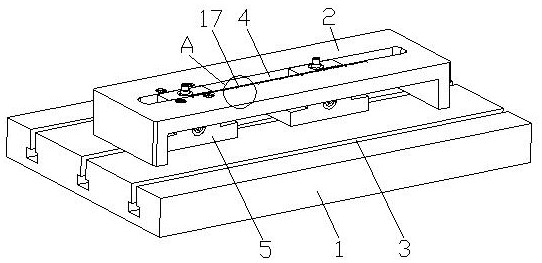

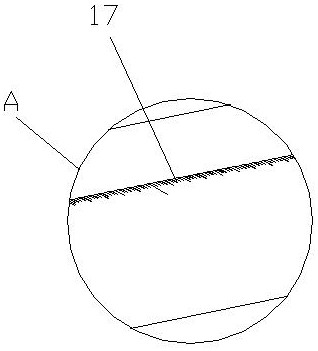

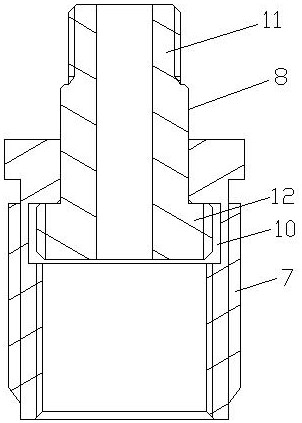

[0035] see Figure 1-Figure 4, a five-sided non-interference machining clamping, including a positioning bottom plate 2 installed on a machine tool table 1, a keyway 3 is opened on the machine tool table 1, and a “one”-shaped groove 4 is opened on the top surface of the positioning bottom plate 2 , two positioning modules 5 are slidably connected to the positioning base plate 2, and the positioning module 5 includes a base 6, an external threaded sleeve 7 and an internal screw 8, and the internal screw 8 is inserted axially along the internal screw 8. The first bevel gear shaft 9, the external thread sleeve 7 is threadedly connected to the internal screw 8, the external thread sleeve 7 is provided with an annular groove 10, and the internal screw 8 includes a screw section 11 and a threaded shoulder section 12. The threaded shoulder section 12 is located below the screw section 11. The threaded shoulder section 12 is integrally formed with the screw section 11. The diameter of...

Embodiment 2

[0038] see Figure 1-Figure 4 , a five-sided non-interference machining clamping, including a positioning bottom plate 2 installed on a machine tool table 1, a keyway 3 is opened on the machine tool table 1, and a “one”-shaped groove 4 is opened on the top surface of the positioning bottom plate 2 , two positioning modules 5 are slidably connected to the positioning base plate 2, and the positioning module 5 includes a base 6, an external threaded sleeve 7 and an internal screw 8, and the internal screw 8 is inserted axially along the internal screw 8. The first bevel gear shaft 9, the external thread sleeve 7 is threadedly connected to the internal screw 8, the external thread sleeve 7 is provided with an annular groove 10, and the internal screw 8 includes a screw section 11 and a threaded shoulder section 12. The threaded shoulder section 12 is located below the screw section 11. The threaded shoulder section 12 is integrally formed with the screw section 11. The diameter o...

Embodiment 3

[0042] see Figure 1-Figure 4 , a five-sided non-interference machining clamping, including a positioning bottom plate 2 installed on a machine tool table 1, a keyway 3 is opened on the machine tool table 1, and a “one”-shaped groove 4 is opened on the top surface of the positioning bottom plate 2 , two positioning modules 5 are slidably connected to the positioning base plate 2, and the positioning module 5 includes a base 6, an external threaded sleeve 7 and an internal screw 8, and the internal screw 8 is inserted axially along the internal screw 8. The first bevel gear shaft 9, the external thread sleeve 7 is threadedly connected to the internal screw 8, the external thread sleeve 7 is provided with an annular groove 10, and the internal screw 8 includes a screw section 11 and a threaded shoulder section 12. The threaded shoulder section 12 is located below the screw section 11. The threaded shoulder section 12 is integrally formed with the screw section 11. The diameter o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com