retractable electric drive manipulator

A manipulator and electric drive technology, applied in the field of manipulators, can solve problems such as poor practicability, achieve good practicability, improve flexibility, and improve the ability to grasp

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

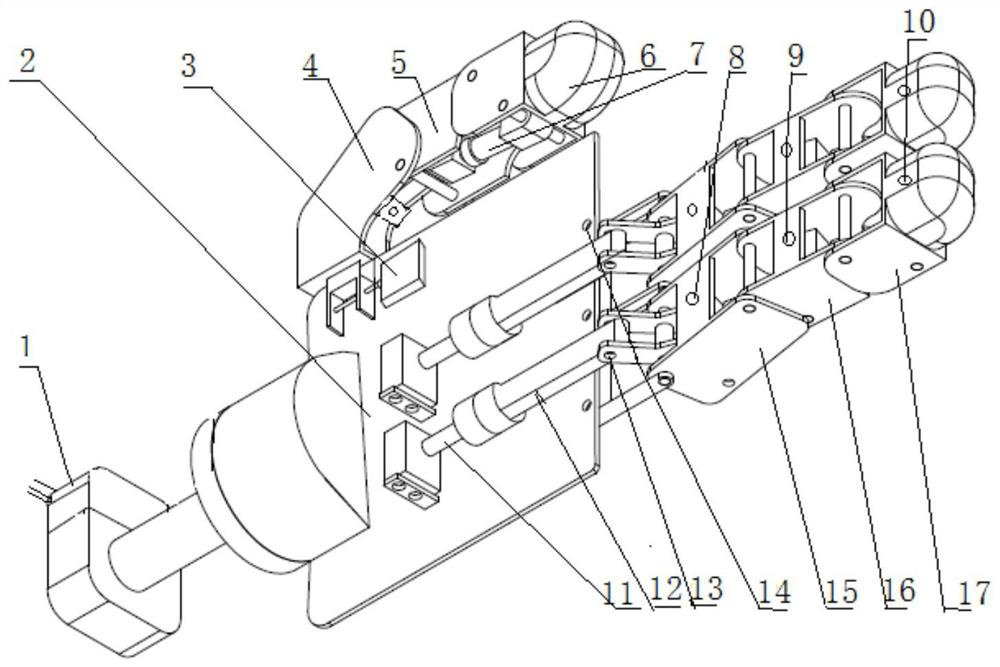

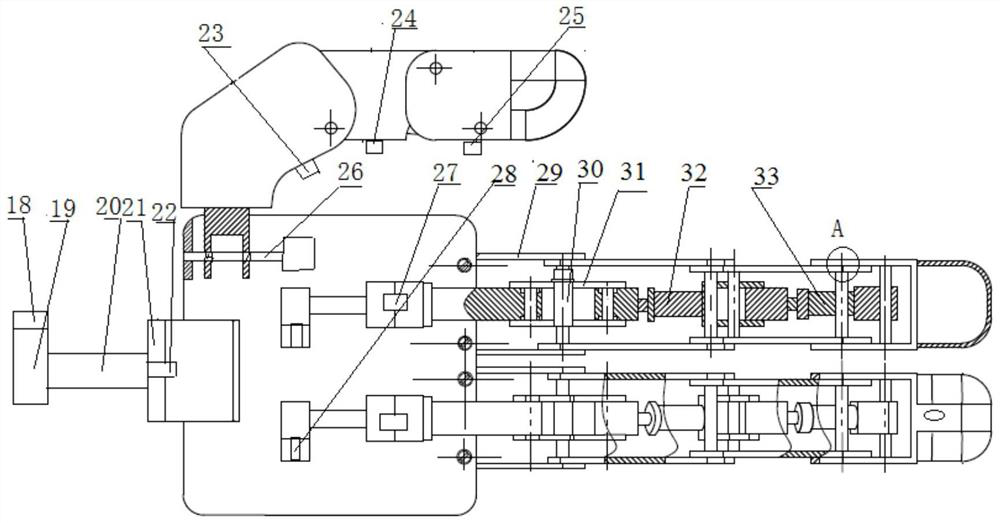

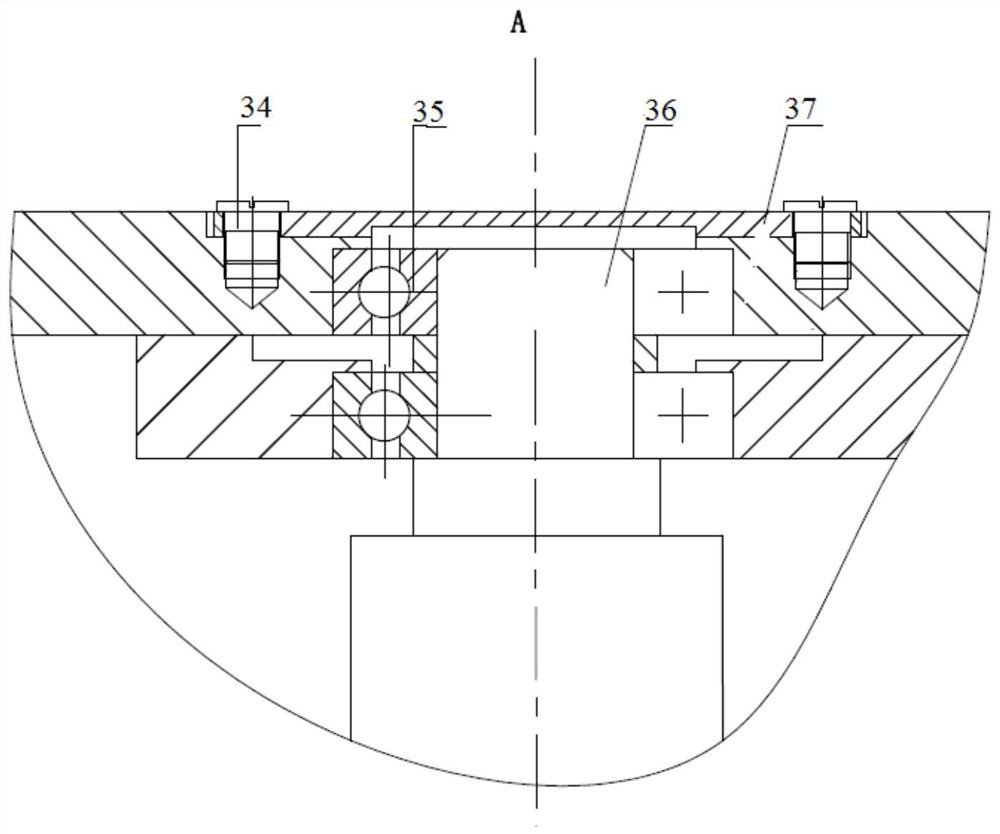

[0019] The following examples refer to Figures 1 to 10 .

[0020] The retractable electric drive manipulator of the present invention includes a palm electromechanical actuator 1, a palm 2, a thumb motor 3, a proximal phalanx of the thumb 4, a middle phalanx of the thumb 5, a distal phalanx of the thumb 6, a thumb electromechanical actuator 7, and a proximal phalangeal sensor 8. Middle knuckle sensor 9, distal knuckle sensor 10, proximal knuckle electromechanical actuator 11, proximal knuckle push rod 12, push rod bolt 13, palm bolt 14, finger proximal knuckle 15, finger middle knuckle 16, finger Distal knuckle 17, actuator motor 18, reducer 19, planetary roller screw 20, nut 21, load bolt 22, thumb proximal knuckle sensor 23, thumb middle knuckle sensor 24, thumb distal knuckle sensor 25, thumb Heel joint shaft 26, finger bolts 27, proximal phalanx electromechanical actuator bolts 28, proximal phalanx connector 29, first shaft 30, middle phalangeal rocker arm 31, middle pha...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com