Stir head for friction stir machining and fabrication of metal matrix composite

A composite material and friction stir technology, applied in metal processing equipment, welding equipment, manufacturing tools, etc., can solve the problems of uneven distribution of reinforcement, large flash and extrusion of reinforcement, and reduce the amount of flash, distribution The effect of homogenizing and increasing the fluidity of plastic metals

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

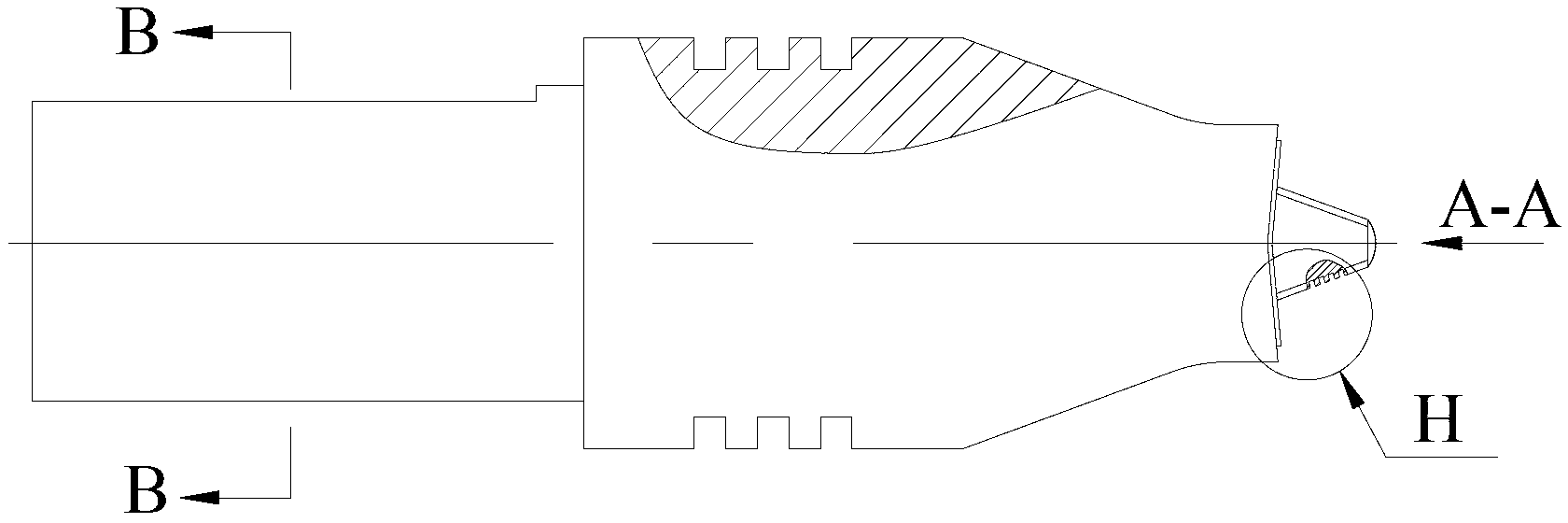

[0024] A stirring head for preparing metal matrix composite materials by friction stir processing, the structure is as above, and the specific dimensions are:

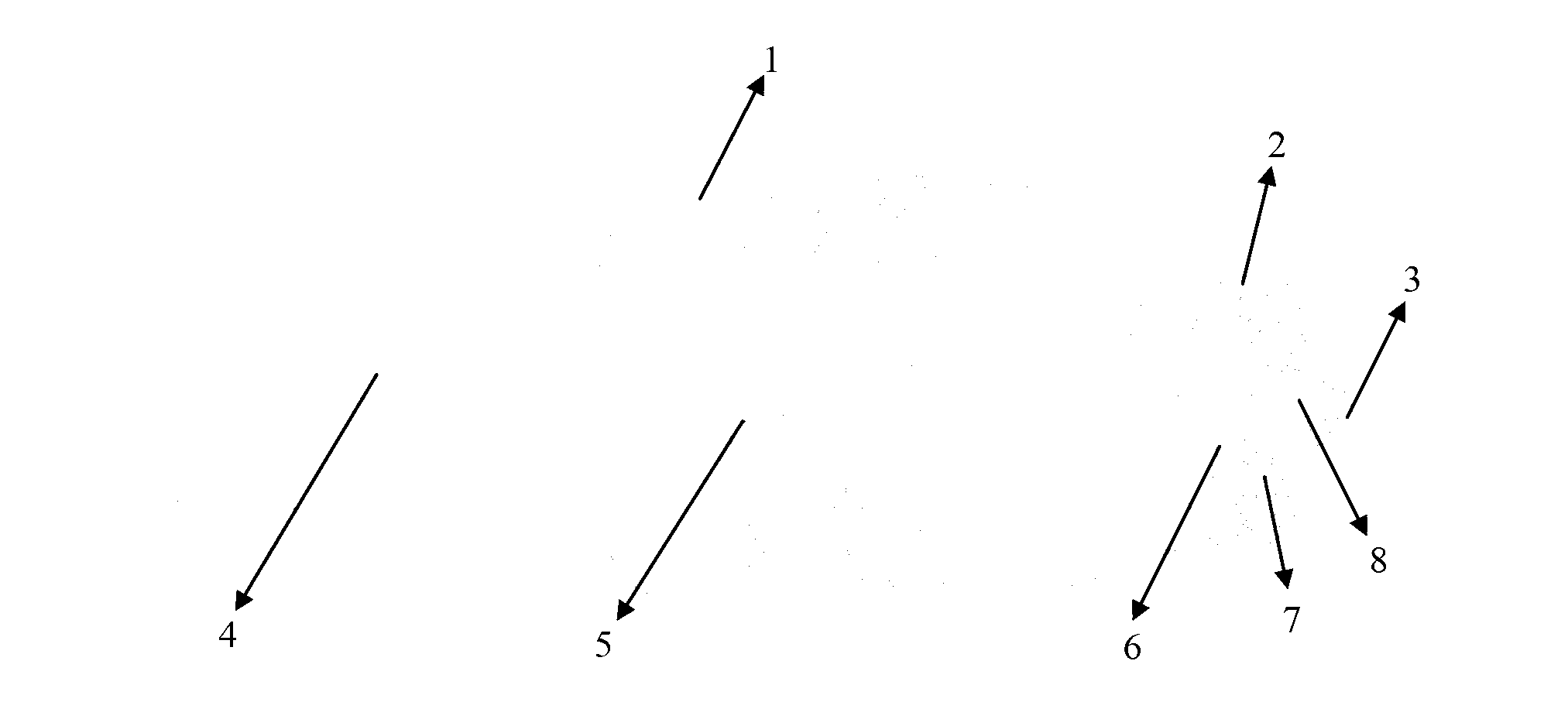

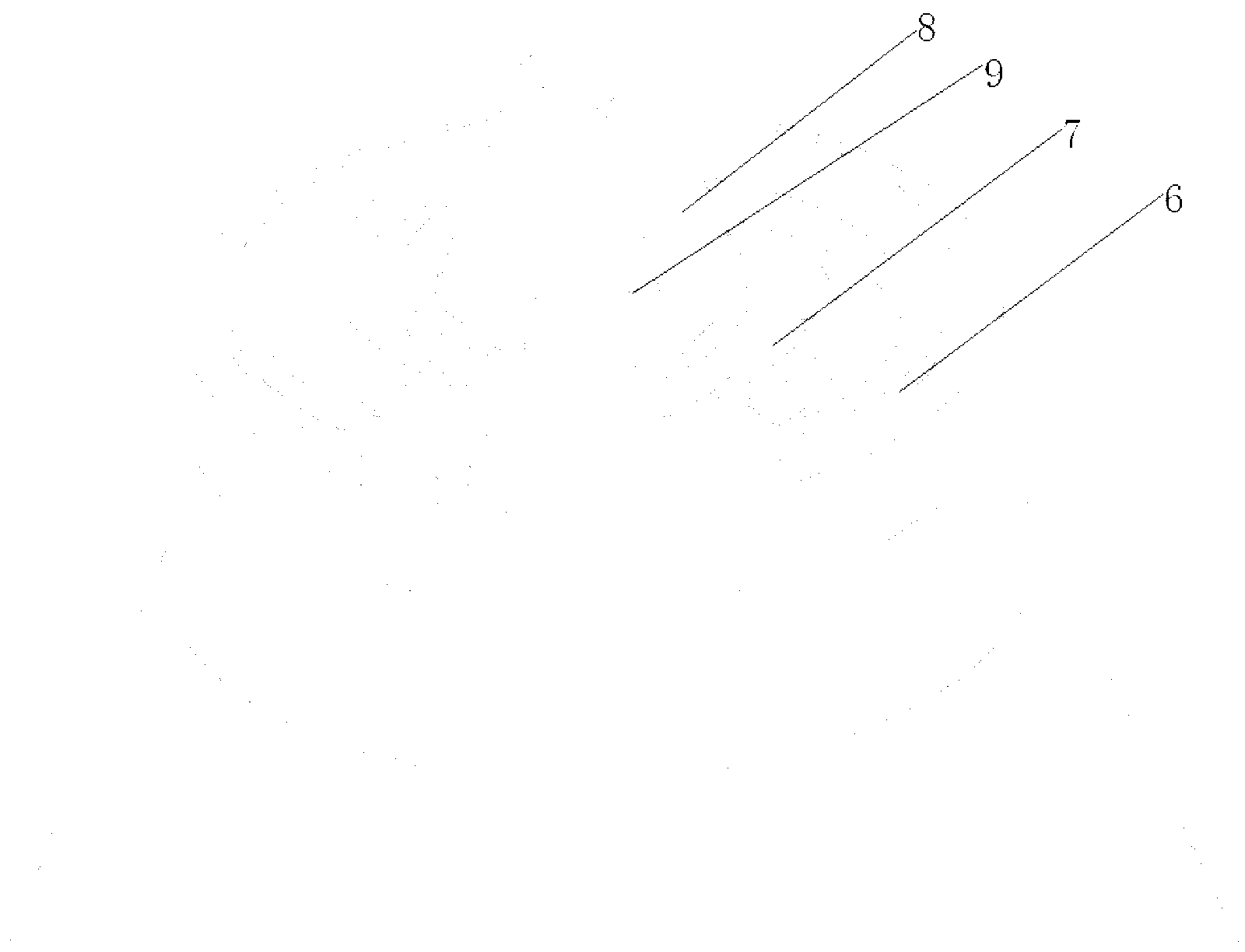

[0025] The width and depth of the cooling groove 5 are 3mm. The shoulder 2 adopts a boss structure, the diameter of the shoulder is 15 mm, the diameter of the boss is 13 mm, the height of the boss is 0.2 mm, the bottom surface of the shoulder is concave, and the boss has three spiral grooves 7 .

[0026] The stirring needle is a cone with a root diameter of 6 mm, an end diameter of 3 mm, and a length of 5.5 mm. The stirring needle is threaded with a pitch of 1 mm. There are three side planes 8 parallel to the bus bar on the stirring needle.

[0027] When preparing metal matrix composites by friction stir processing, the substrate used is a 10mm thick 6061 aluminum alloy plate, and the reinforcement is Al with an average particle size of 50nm. 2 o 3 For particles, the processing parameters are as follows: rotation spe...

PUM

| Property | Measurement | Unit |

|---|---|---|

| height | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com