Material plate distribution device of cartoning machine and its cartoning machine

A technology of cartoning machine and material board, which is applied in the direction of packaging, etc., can solve the problems of overlapping structure of swing rod parts, easy throwing on the partition, feeding failure and other problems, so as to improve stability and reliability, expand the scope of application, Change the effect of unloading misalignment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

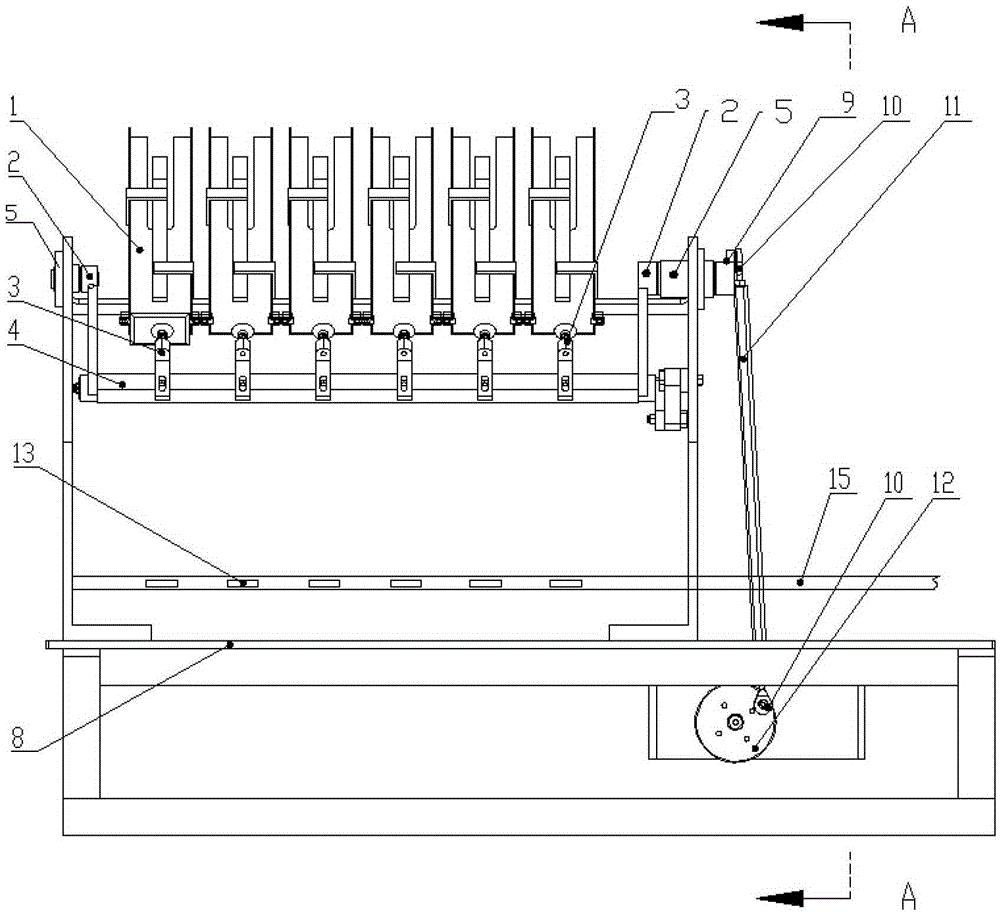

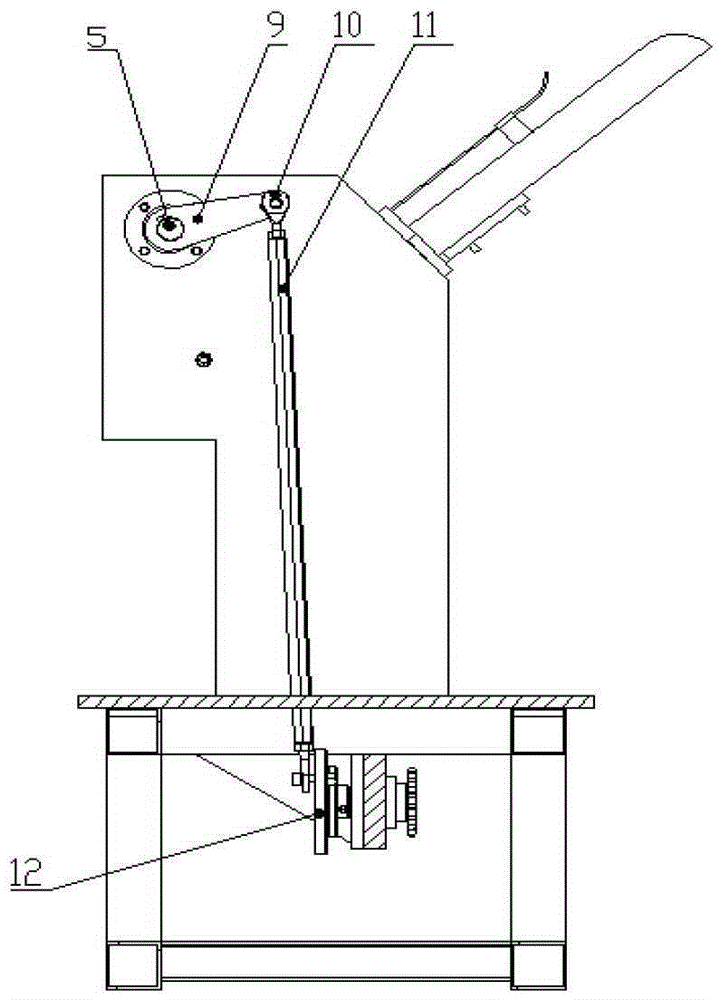

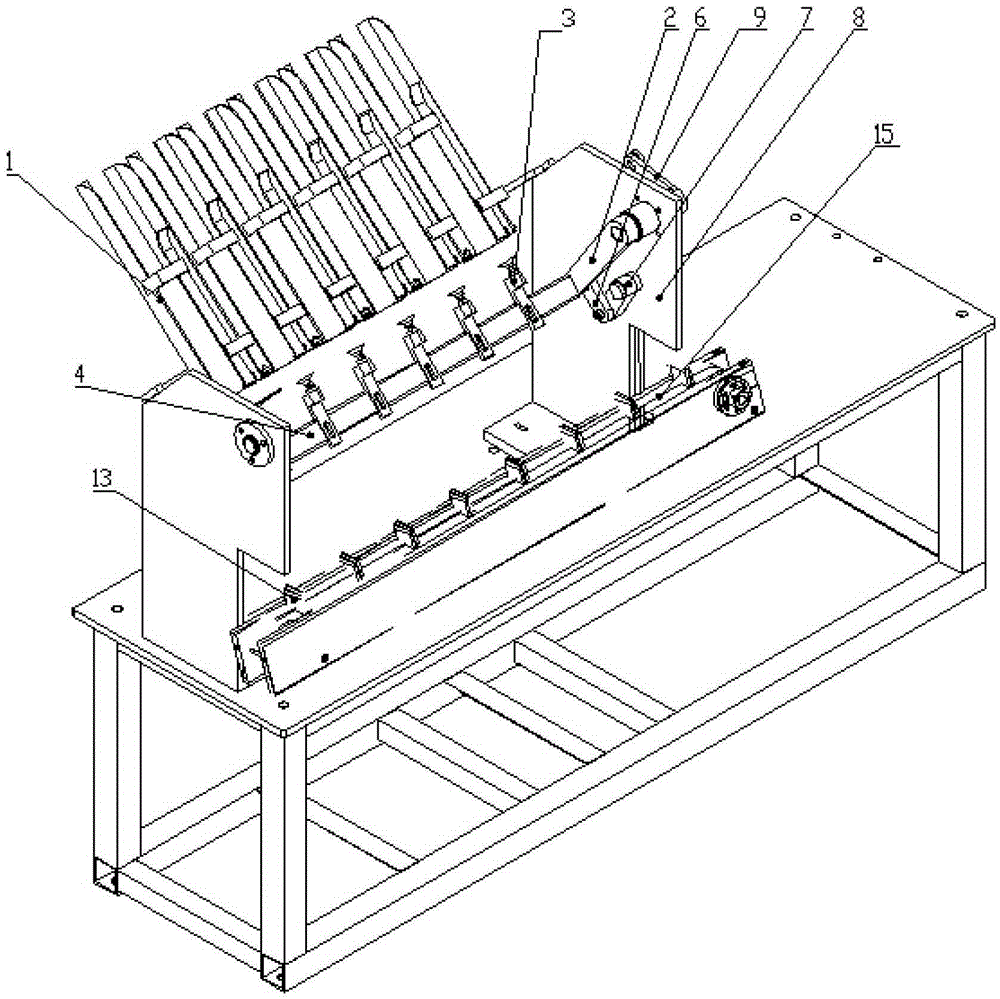

[0014] The present invention will be described further by embodiment now in conjunction with accompanying drawing. The hopper of the material plate distribution device of the present invention can be located at any position in the conveying direction of the conveyor belt on the upper part of the collecting chamber, that is, it can be installed directly above the conveyor belt (synchronous conveyor belt) or on the conveyor belt. Above one side of the belt; the axial direction of the movable pendulum shaft of the material sheet distribution device can be the same as the conveying direction of the conveyor belt, or the two form an angle less than 10 degrees with each other, and the suction cup assembly of the material sheet distribution device ( Suction cup) rotates or swings along the transverse direction of the conveyor belt, or rotates or swings around the conveying direction line of the conveyor belt.

[0015] The present embodiment of material plate distributing device is fo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com