Paddy rice collecting machine in farmyard

A technology of collecting machine and rice, applied in the field of agricultural machinery, can solve the problems of slow work efficiency and large manpower, and achieve the effects of high work efficiency, reduced labor intensity and saving manpower

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

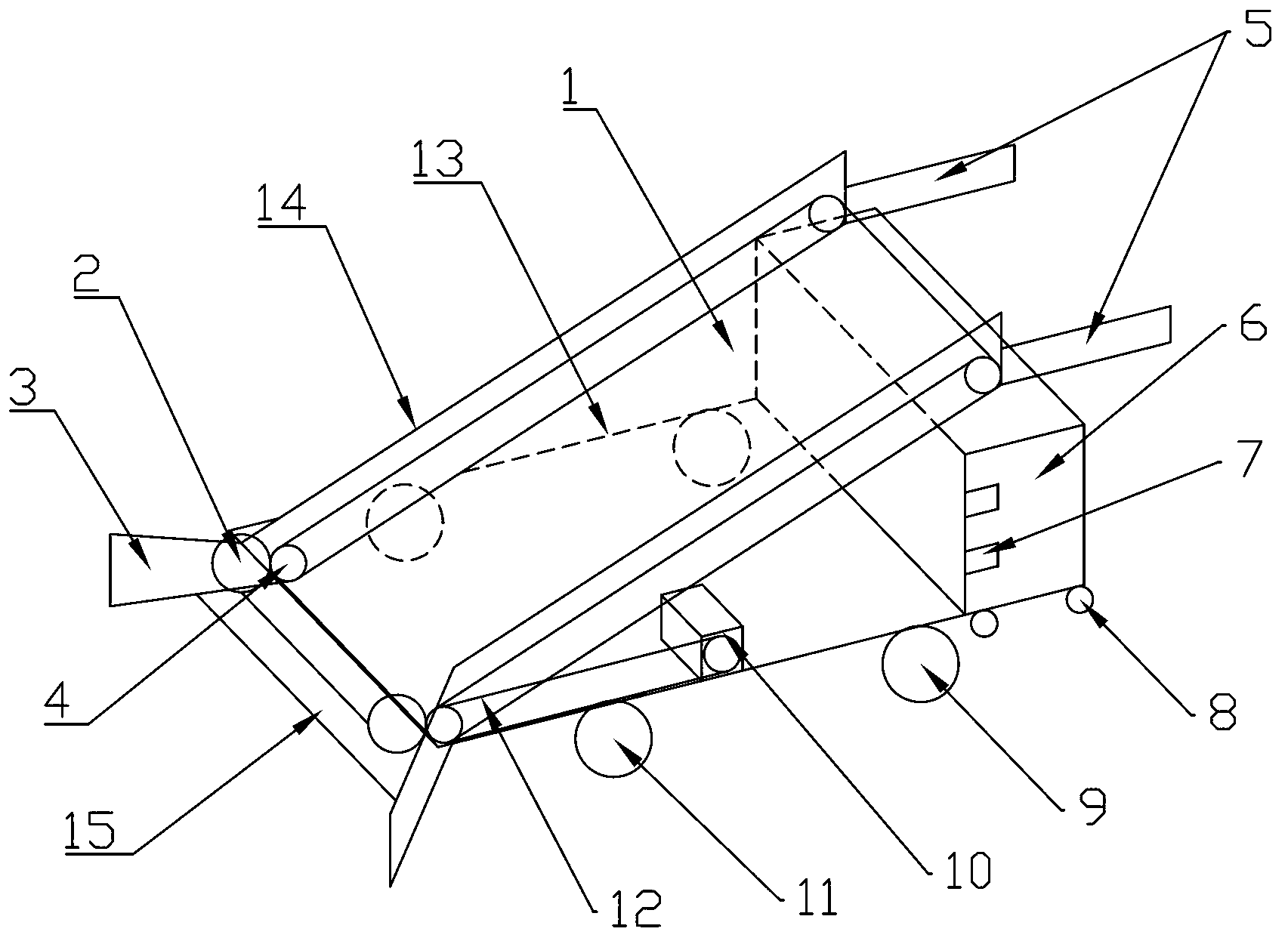

[0016] like figure 1 shown. A kind of paddy collecting machine between field, comprises frame 13, and described frame 13 comprises horizontal base plate, and one end of base plate is provided with a riser perpendicular to it, and one side of riser is connected with base plate, and the other end of riser Side is provided with grain storage device; The bottom plate of frame 13 is provided with a motor 10, is connected by transmission belt 12 between the output shaft of motor 10 and conveyor belt shaft wheel 4, and conveyor belt 1 one end is positioned at the outer end of frame 13 bottom plates, and conveyor belt 1. The other end extends to the top of the grain storage device through the top of the vertical plate of the frame 13; a sweeping wheel 2 tangent to it is provided on the outside obliquely above the lower end of the conveyor belt 1.

[0017] The bottom of the base plate of described frame 13 is provided with two groups of road wheels, and described road wheels comprises...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap