Automatic cover pressing machine of plastic covers

A technology of plastic caps and capping machines, which is applied to flange-type caps and other directions, can solve the problems of production stoppage, insufficient pressing, leakage pressure, etc., and achieve the increase of capping speed, high capping speed, and avoid leakage of pressure. effect of the phenomenon

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

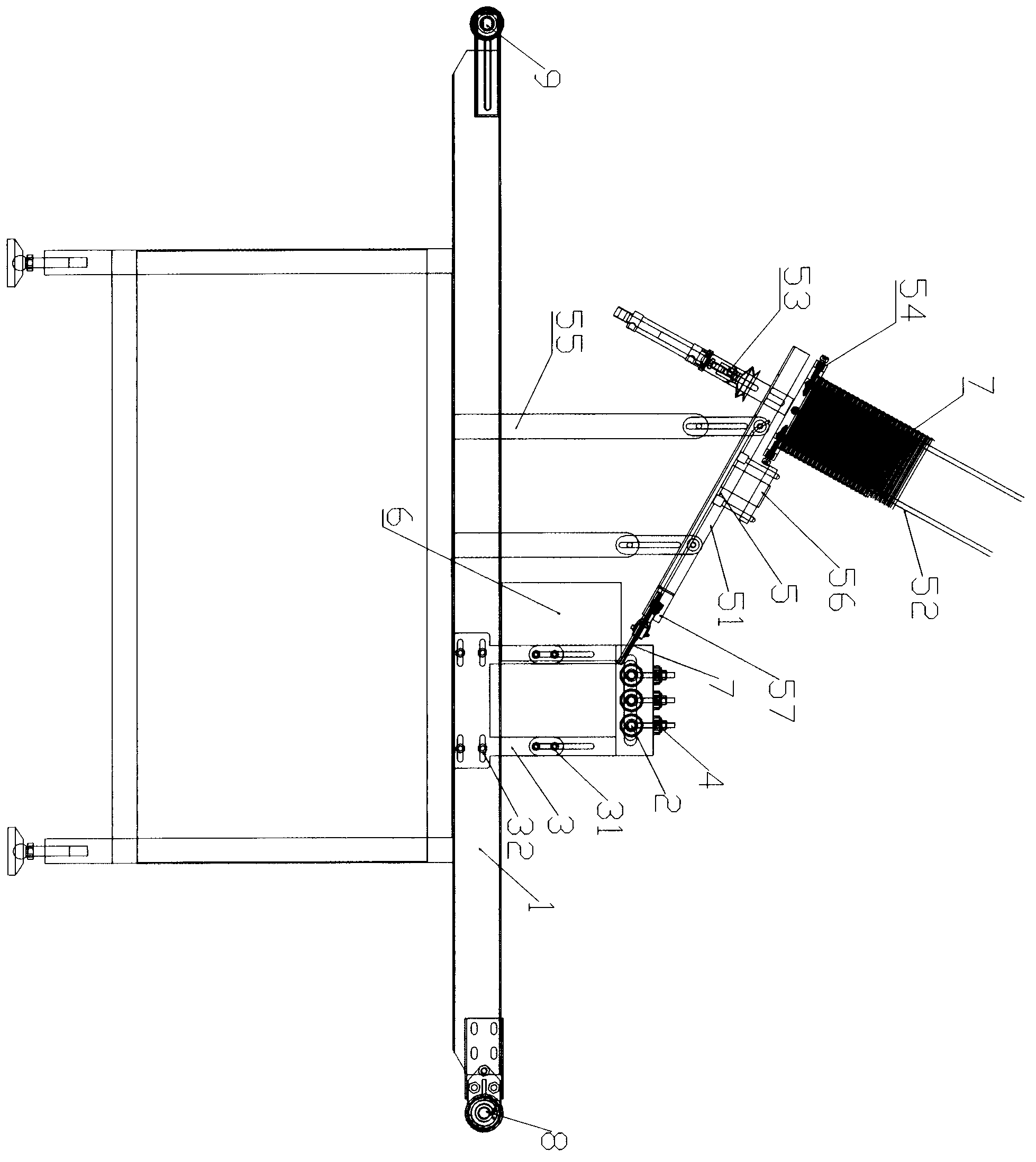

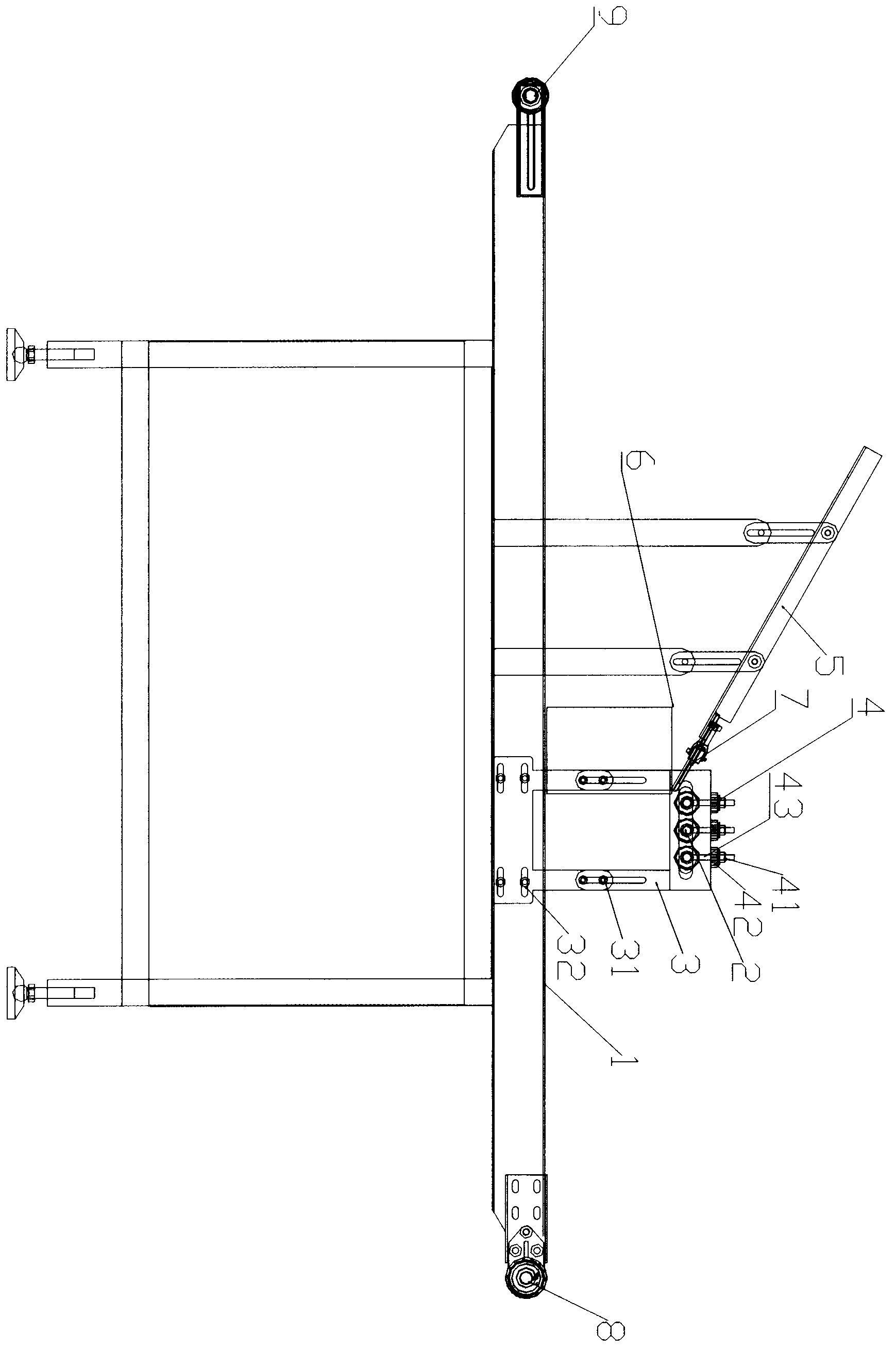

[0029] like Figure 1 ~ Figure 4 Shown: an automatic capping machine for plastic caps, including a pressing mechanism for pressing the plastic cap on the iron can; a conveying mechanism for transporting the plastic cap to the entrance of the pressing mechanism;

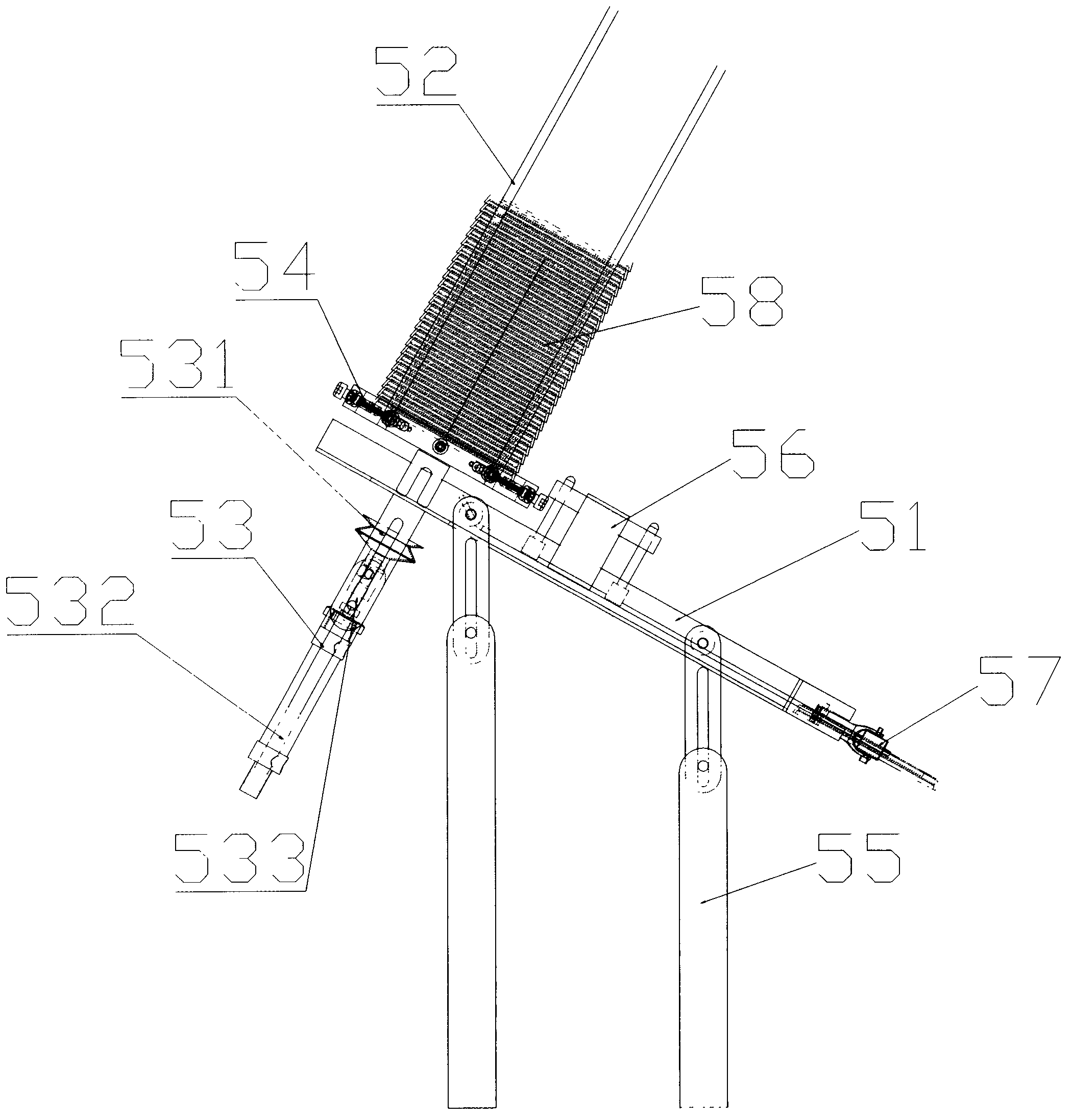

[0030] The conveying mechanism 5 includes a slideway 51 that allows the plastic cover 7 to slide to the plastic cover pressing mechanism, a cap loading mechanism 52 that can accommodate a plurality of plastic covers 7 above the front end of the slideway 51, and a cover loading mechanism 52 located on the top of the front end of the slideway 51. The bottom of the plastic cover 7 is sucked to the suction cup mechanism 53 on the slideway 51; the bottom of the cover loading mechanism 52 is also provided with a first spring mechanism for supporting the plastic cover 7. The cover loading mechanism 52 and the slideway 51 are arranged vertically, and the cover loading mechanism 52 and the suction cup mechanism 53 are arranged...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com