Ground-adaptive differential-drive floating wheel system

A technology of differential drive and floating wheel, which is applied to motor vehicles, transportation and packaging, etc. It can solve the problems of unsatisfactory stability of floating wheels, harsh application sites, and high cost, and achieves easy installation and debugging, convenient disassembly and maintenance, and simple structure Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

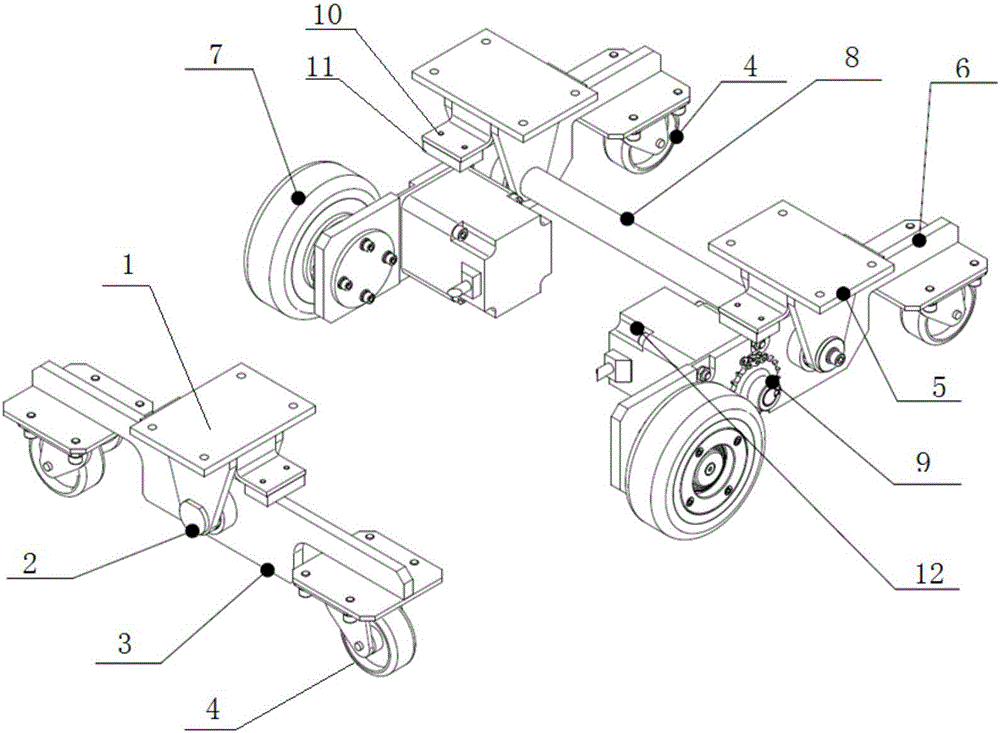

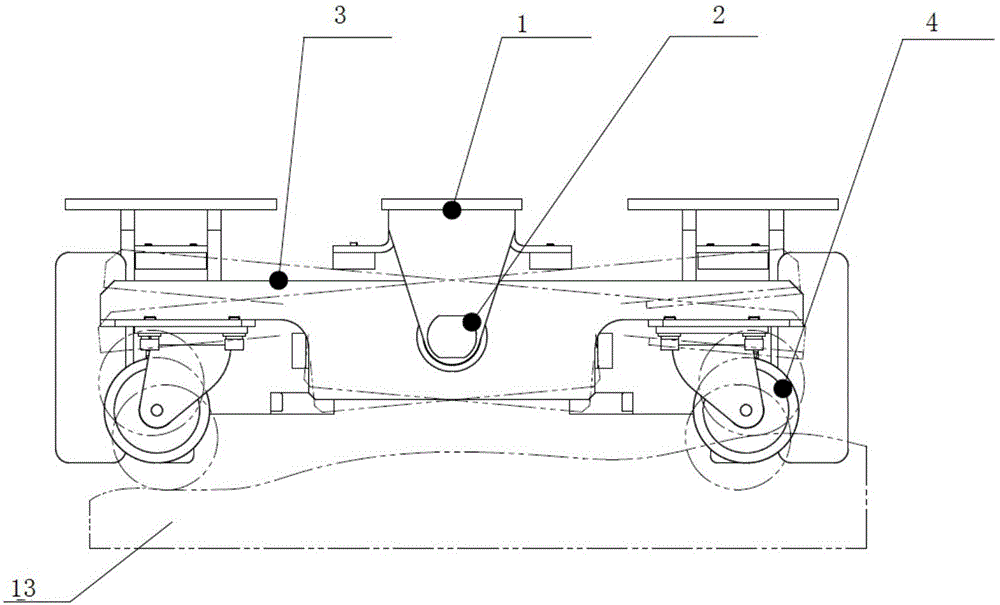

[0018] Embodiment 1: as figure 1 As shown, a ground adaptive differential drive floating wheel train includes a front wheel set and a rear wheel set. When the front wheel set and the rear wheel set are placed on the level ground 13, they are flush on the same horizontal plane. The front wheel set includes The front fork bracket 1, the front fork bracket 1 is used to install the main body of the mobile trolley, the front fork bracket 1 is connected to the horizontal floating rod 3 through the fulcrum shaft 2, and the horizontal floating rod 3 can use the fulcrum shaft 2 as the fulcrum to move up and down Undulating and rotating movement, universal wheels 4 are installed under the two ends of the horizontal floating rod 3; in actual use, the front wheels are front wheels, and the universal wheels 4 can provide the steering requirements of the trolley; The longitudinal floating wheels of the horizontal floating bar 3 are formed, the rear wheel group has only one group of longitud...

Embodiment 2

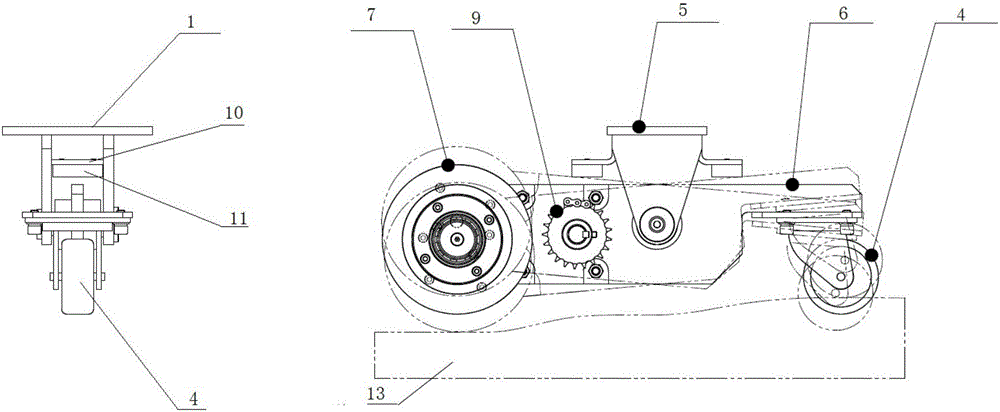

[0019] Embodiment 2: as figure 2 as shown, image 3 As shown, on the basis of Embodiment 1, a sprocket 9 connected to the drive motor 12 is installed on the outer surface of the longitudinal floating bar 6, and the sprocket 9 is transmission connected to the drive wheel 7, and the drive wheel 7 is a Rubber wheels. Here, the drive wheel 7 is driven by the sprocket 9 and the chain, which is only one of the transmission methods, and the drive wheel 7 can also be directly installed on the rotating shaft of the drive motor 12 to provide driving, or gear transmission, belt transmission, etc. can also be used. carry out transmission;

[0020] The front fork bracket 1 and the rear fork bracket 5 are respectively provided with a limit guard 10 extending downwards below the two ends in the direction of the horizontal floating bar 3 and the longitudinal floating bar 6, and the limit guard 10 Corresponding to the respective horizontal floating rods 3 or vertical floating rods 6 direct...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com