Side sliding door of railway vehicle

A technology for rail vehicles and side sliding doors, which is applied in vehicle locks, door leaves, door devices, etc., can solve problems such as hidden safety hazards, affect sealing ability, and increase vehicle operating costs, achieve high sealing ability, and improve the effect of use flexibility.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

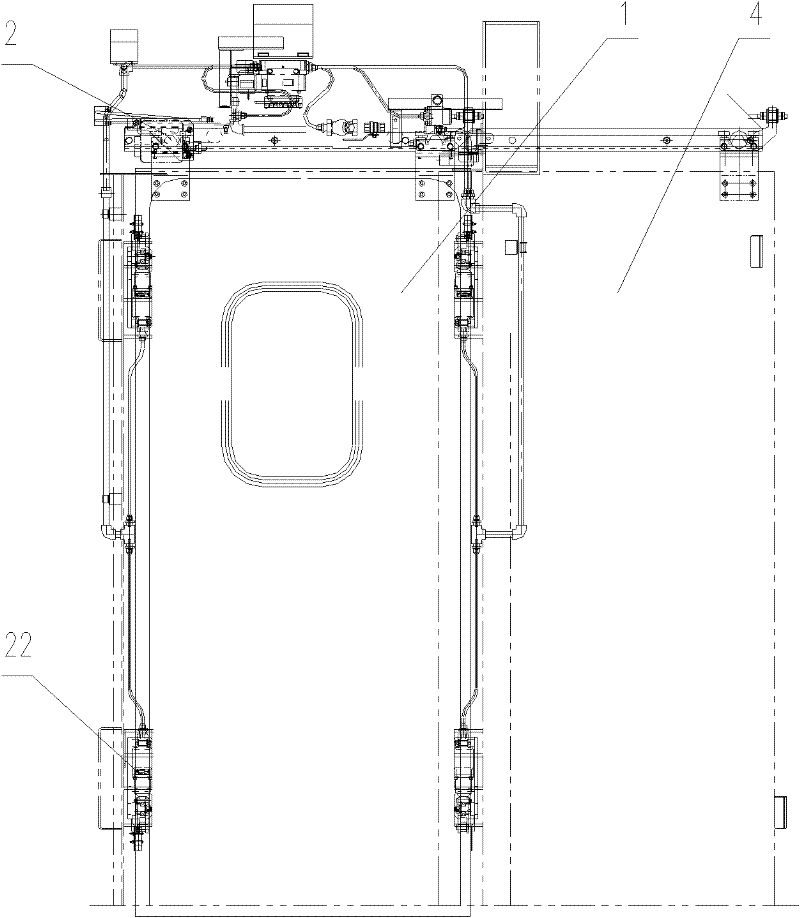

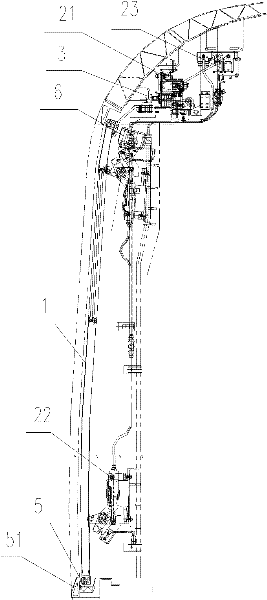

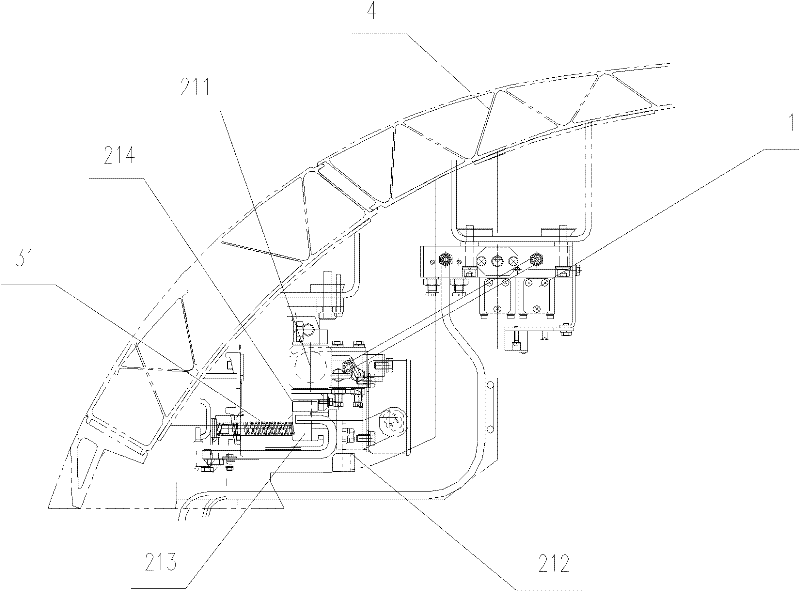

[0048] Such as Figure 1 to Figure 7 As shown, the rail vehicle side sliding door is integrally arranged inside the car body 4, and the door body 1 is pressed and sealed to the door frame 10 on the car body by the control device 2 .

[0049] The side sliding door mainly includes a door body 1 , a control device 2 , a reset adjustment device 3 , a drainage assembly 5 and an isolation lock 6 . in,

[0050] The control device 2 is used to control the opening and closing action state of the door body 1;

[0051] The reset adjustment device 3 is to realize the state before the door body 1 resumes action in the open state;

[0052] After the door body 1 is closed, the pressure acting on the door body 1 is maintained by the control device 2 .

[0053] The side sliding door adopts an electro-pneumatic built-in structure, and the compression sealing of the side sliding door is realized by the air pressure locking part 22 . After the compressed air is input into the air pressure lin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com