Method for eliminating medium-temperature island-shaped structures during normalization of 15NiCuMoNb5 steel

A technology of normalizing and organizing, which is applied in the field of elimination of medium-temperature island structures, and can solve the problems of reducing toughness and impact properties that are difficult to meet the requirements of use.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

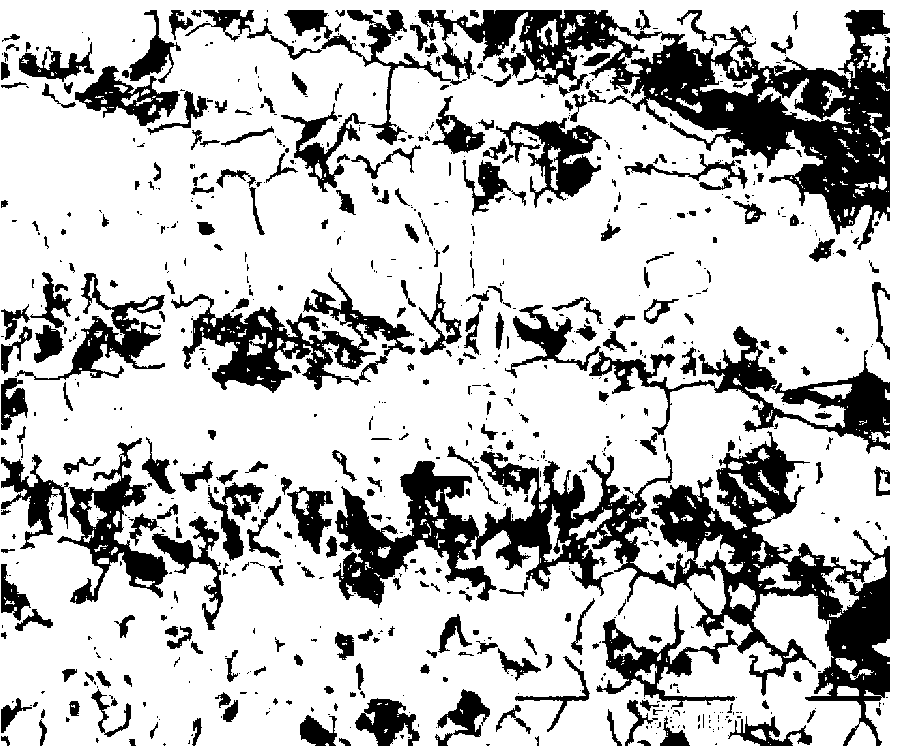

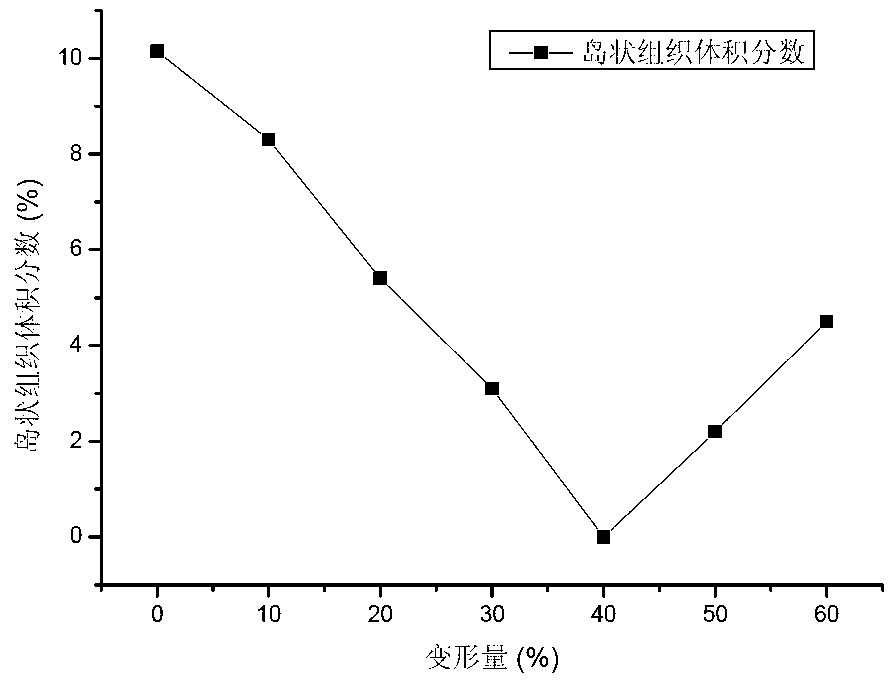

[0022] Take 15NiCuMoNb5 steel pipes or plates, and cut cylindrical samples with wire cutting. The sample size is 5mm×5mm×20mm. Processing in the experimental device: set the program as follows: the heating rate is 20K / min, from room temperature to the austenite zone of 1173K, keep warm for 5 minutes, then start rolling and deformation by 10%, and then cool at 5K / min after deformation rate down to room temperature.

[0023] The volume fraction of island structure in the 15NiCuMoNb5 steel structure controlled by the austenite zone is reduced from 10.2% to 8.1%, the volume fraction of ferrite is 90.2%, and the impact energy at room temperature is increased from 27J to 39J.

Embodiment 2

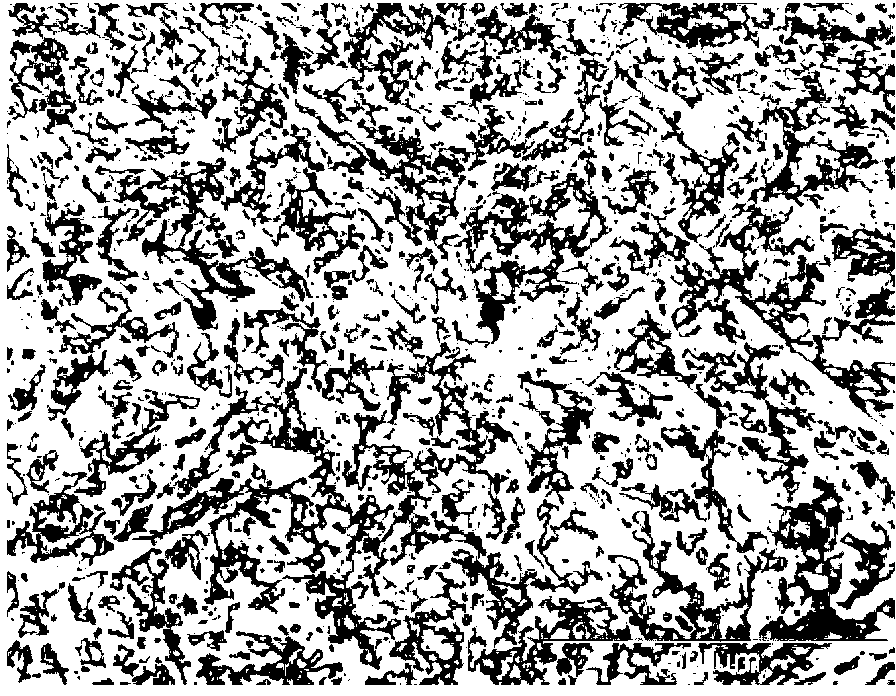

[0025] Take 15NiCuMoNb5 steel pipe or plate, and cut cylindrical sample with wire cutting. The sample size is 3mm×3mm×40mm; Processing in the experimental device: set the program as follows: the heating rate is 100K / min, from room temperature to the austenite zone of 1253K, keep warm for 10 minutes, and then start rolling deformation, the deformation amount is 60%, respectively, after deformation Cool down to room temperature at a cooling rate of 20K / min.

[0026] The island structure volume fraction in the 15NiCuMoNb5 steel microstructure controlled by the austenite zone is reduced from 10.2% to 7.5%, the ferrite volume fraction is 91.2%, and the impact energy at room temperature is increased from 27J to 43J.

Embodiment 3

[0028] Take 15NiCuMoNb5 steel pipes or plates, and cut cylindrical samples with wire cutting. The sample size is 5mm×5mm×30mm; Processing in the experimental device: the setting program is: the heating rate is 40K / min, from room temperature to the austenite zone of 1223K, heat preservation for 7 minutes, and then rolling deformation, the deformation amount is 40%, respectively, and then Cool down to room temperature at a cooling rate of 15K / min.

[0029] The island structure volume fraction in the 15NiCuMoNb5 steel microstructure controlled by the austenite zone is reduced from 10.2% to 2.2%, the ferrite volume fraction is 95.1%, and the impact energy at room temperature is increased from 27J to 48J.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Impact energy at room temperature | aaaaa | aaaaa |

| Impact energy at room temperature | aaaaa | aaaaa |

| Impact energy at room temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com