Method for eliminating medium-temperature island-shaped structures during normalization of 15NiCuMoNb5 steel

A normalizing and microstructure technology, applied in the field of elimination of mesophilic island structure, can solve the problems of reducing toughness, impact performance difficult to meet the requirements of use, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

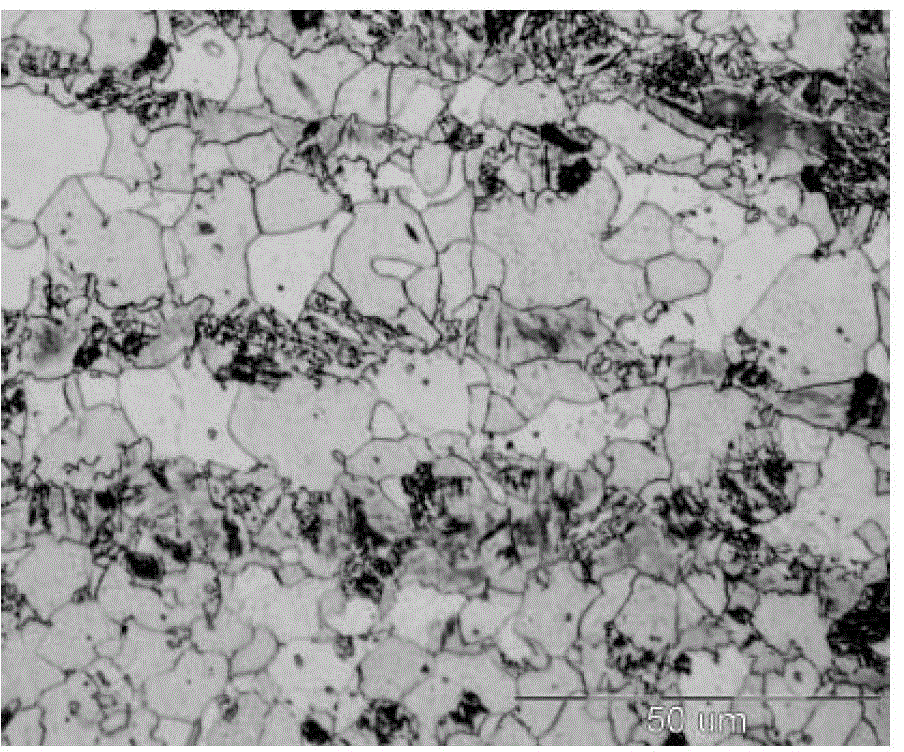

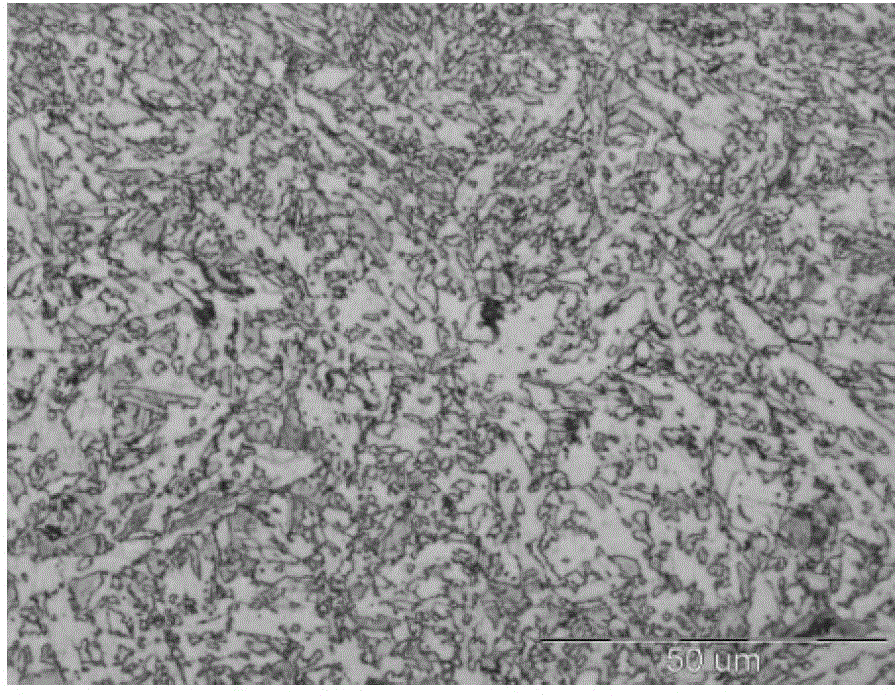

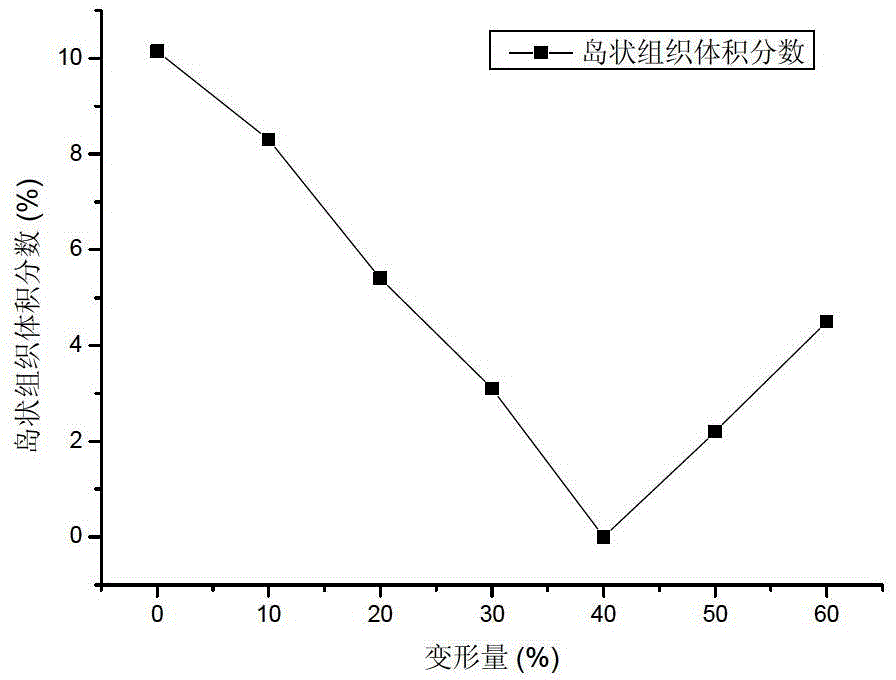

[0022] Take 15NiCuMoNb5 steel pipes or plates, and cut cylindrical samples with wire cutting. The sample size is 5mm×5mm×20mm. Processing in the experimental device: set the program as follows: the heating rate is 20K / min, from room temperature to the austenite zone of 1173K, keep warm for 5 minutes, then start rolling and deformation by 10%, and then cool at 5K / min after deformation rate down to room temperature.

[0023] The volume fraction of island structure in the 15NiCuMoNb5 steel structure controlled by the austenite zone is reduced from 10.2% to 8.1%, the volume fraction of ferrite is 90.2%, and the impact energy at room temperature is increased from 27J to 39J.

Embodiment 2

[0025] Take 15NiCuMoNb5 steel pipe or plate, and cut cylindrical sample with wire cutting. The sample size is 3mm×3mm×40mm; Processing in the experimental device: set the program as follows: the heating rate is 100K / min, from room temperature to the austenite zone of 1253K, keep warm for 10 minutes, and then start rolling deformation, the deformation amount is 60%, respectively, after deformation Cool down to room temperature at a cooling rate of 20K / min.

[0026] The island structure volume fraction in the 15NiCuMoNb5 steel microstructure controlled by the austenite zone is reduced from 10.2% to 7.5%, the ferrite volume fraction is 91.2%, and the impact energy at room temperature is increased from 27J to 43J.

Embodiment 3

[0028] Take 15NiCuMoNb5 steel pipes or plates, and cut cylindrical samples with wire cutting. The sample size is 5mm×5mm×30mm; Processing in the experimental device: the setting program is: the heating rate is 40K / min, from room temperature to the austenite zone of 1223K, heat preservation for 7 minutes, and then rolling deformation, the deformation amount is 40%, respectively, and then Cool down to room temperature at a cooling rate of 15K / min.

[0029] The island structure volume fraction in the 15NiCuMoNb5 steel microstructure controlled by the austenite zone is reduced from 10.2% to 2.2%, the ferrite volume fraction is 95.1%, and the impact energy at room temperature is increased from 27J to 48J.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com