Flexible manufacturing method of hot-rolled structural steel plate

A flexible manufacturing and structural steel plate technology, applied in the field of metallurgical technology, can solve the difficulty of increasing the organization of production, it is difficult to solve the problems of diversified user needs and production technology, organization management, and increase production costs, so as to improve the production rhythm and The effect of management efficiency, reduction of production cost, and saving of alloy resources

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

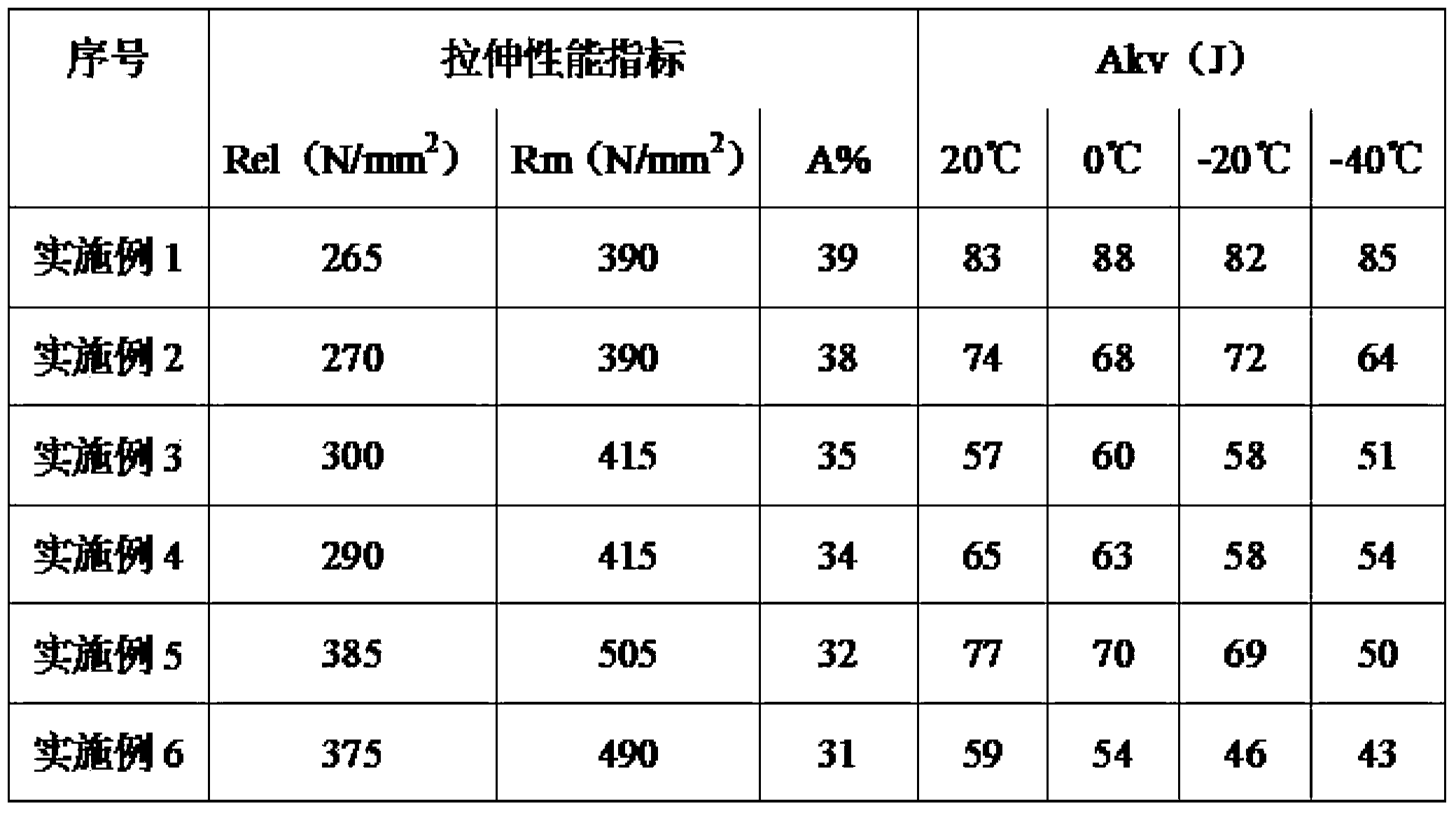

Examples

Embodiment 1

[0029] Example 1: Production of 245 MPa strength level hot-rolled steel plate.

[0030] Its chemical composition weight percentage is: C0.17%, Si0.10%, Mn0.4%, P0.018%, S0.010%, and the remainder is Fe and unavoidable impurities.

[0031] Continuous rolling process: heating temperature 1150°C, rough rolling entry temperature 1060°C, finish rolling start temperature 1010°C, final rolling temperature 860°C, deformation per pass 23%, uniform laminar cooling after rolling. The cooling rate is 13°C / s, and the coiling temperature is 620°C.

Embodiment 2

[0032] Example 2: Production of 245 MPa strength grade hot-rolled steel plate.

[0033] Its chemical composition weight percentage is: C0.19%, Si0.12%, Mn0.25%, P0.010%, S0.014%, and the remainder is Fe and unavoidable impurities.

[0034] Continuous rolling process: heating temperature 1140°C, rough rolling start temperature 1055°C, finish rolling start temperature 1005°C, finish rolling temperature 850°C, deformation per pass 22%, uniform laminar cooling after rolling. The cooling rate is 9°C / s, and the coiling temperature is 630°C.

[0035] Produced according to the above-mentioned process of Examples 1 and 2, the finished product structure after rolling is ferrite and a small amount of pearlite existing in the grain boundary, the average ferrite grain size is 10-12 μm, and the pearlite content is 8-12%.

Embodiment 3

[0036] Embodiment 3: Production of 275MPa strength level structural strip steel.

[0037] The weight percentage of its chemical composition is: C0.17%, Si0.10%, Mn0.40%, P0.009%, S0.010%, and the remainder is Fe and unavoidable impurities.

[0038] A two-stage controlled rolling process is adopted:

[0039] a. The rolling temperature in the first-stage recrystallization zone is 1050°C, rolling for 5 passes, and the deformation in each pass is 28%; the thickness of the billet to be warmed is 25mm for the finished product.

[0040] b. The rolling temperature in the second stage is 985°C, the rolling is 9 passes, the cumulative deformation is 67%, and the final rolling temperature is 835°C.

[0041] c. Uniform laminar cooling after rolling; cooling rate 16°C / s; coiling temperature 590°C.

PUM

| Property | Measurement | Unit |

|---|---|---|

| yield strength | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com