Melt spinning structure

A technology of textile structure and melt extrusion, which is applied in textiles and papermaking, fiber processing, filament/thread forming, etc. It can solve the problems of poor thermal insulation ability of synthetic fibers, increase thermal insulation performance and reduce melt The effect of usage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] Below in conjunction with accompanying drawing and embodiment the present invention is further described:

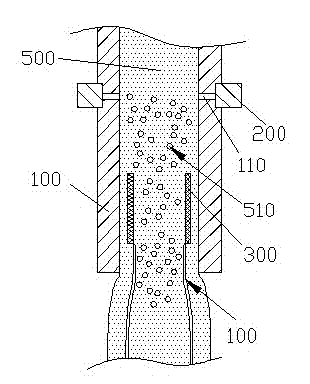

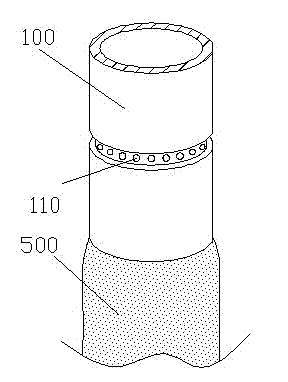

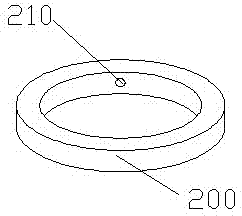

[0018] refer to figure 1 with Figure 4 , in this embodiment, the melt spinning structure includes a melt extruder, a spinneret 100 and a cooling box, the spinneret 100 is arranged at the bottom of the melt extruder, and the spinneret The nozzle of 100 is placed in the cooling box downwards, the spinneret 100 is a cylindrical hollow tube, and the inner wall of the spinneret 100 is evenly distributed with through holes 110 on the circumference, and the through holes 110 In communication with the air injection device, the spinneret 100 is coaxially provided with a heat conduction ring 300 between the through hole 110 and the nozzle. Contact, the semiconductor cooling fins are evenly distributed in the heat conducting ring 300 , the cold surface of the semiconductor cooling fins is located inside the heat conducting ring 300 , and the hot surface of the semiconduct...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com