A fracturing sliding sleeve that can be opened and closed multiple times

A fracturing sliding sleeve and fracturing technology, applied in the direction of production fluid, wellbore/well valve device, wellbore/well components, etc., can solve problems such as gas breakthrough, premature water breakthrough in the wellbore, unfavorable production capacity, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The present invention will be further described below in conjunction with the accompanying drawings and embodiments, but not as a limitation of the present invention.

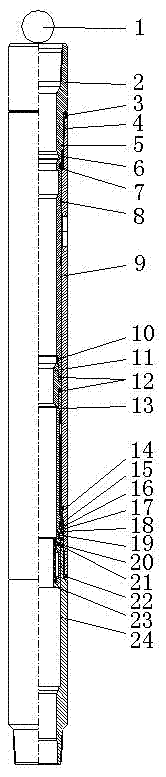

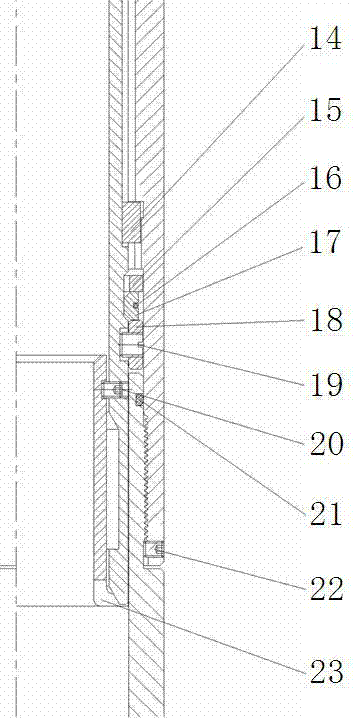

[0017] This embodiment provides a fracturing sliding sleeve that can be opened and closed multiple times, such as figure 1 and figure 2 As shown, including 1. Fracturing ball, 2. Upper joint, 3. Set screw, 4. Fracturing sleeve, 5. No. 1 O-ring, 6. Sand control ring, 7. Sand scraping ring, 8. Vulcanized seal Ring, 9, upper inner sliding sleeve, 10, No. 2 O-ring, 11, ball seat, 12, set screw, 13, lower inner sliding sleeve, 14, key, 15, retaining ring, 16, No. 3 O-type Ring, 17, positioning ring, 18, shear ring, 19, No. 1 shear pin, 20, No. 2 shear pin, 21, No. 1 O-ring, 22, set screw, 23, protective sleeve, 24, Lower connector.

[0018] The upper sand scraping ring 7, vulcanized sealing ring 8, upper inner sliding sleeve 9, No. 2 O-ring 10, ball seat 11, set screw 12, lower inner sliding sleeve 13 and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com