Wet-type concrete spray unit

A wet type, unit technology, applied in wellbore lining, tunnel lining, underground chamber, etc., can solve the problems of low rebound rate, small operation dust, high rebound rate, improve work efficiency and service life, reduce cleaning and waste. The effect of maintenance workload and capacity improvement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The present invention will be further described below in conjunction with accompanying drawing:

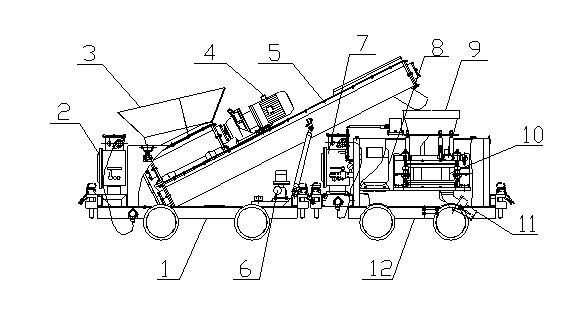

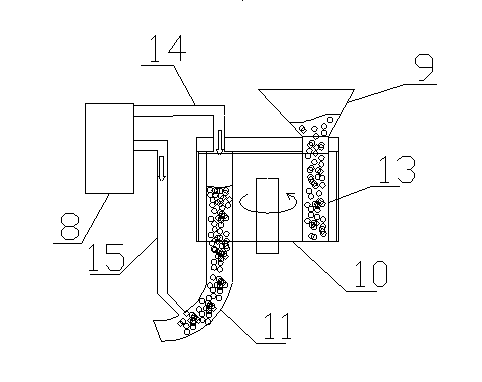

[0024] as attached figure 1 A wet concrete injection unit is shown, which includes a feeding machine and a spraying machine. The feeding machine includes a magnetic starter I2 arranged on the frame I1, a feeding machine hopper I3, a feeding motor I4 and a screw feeding machine. Device 5, composed of water adding device, the water adding device is set in the hopper I3, the feeder hopper I3 is set above the screw feeding device 5 and communicated with the bolt feeding device 5, and the screw feeding device 5 is provided with a stirring blade with a spiral blade Shaft, feeding motor Ⅰ4 is fixedly installed above the screw feeding machine 5 to provide power for the screw feeding device 5. The middle section of the screw feeding device 5 is connected to the frame Ⅰ1 through an adjustable bracket, and the frame Ⅰ1 is also equipped with a quick-setting Agent adding device 6;

[...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com