A circulation pump sealing structure under negative pressure/normal pressure state

A sealed structure, circulating pump technology, applied in the parts, pumps, pump elements, etc. of the pumping device for elastic fluid, can solve the problem of difficult suction and pumping, reduced performance and service life, pump function failure, etc. problems, to achieve the effect of extending the service life, ensuring continuous use, and avoiding dry friction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

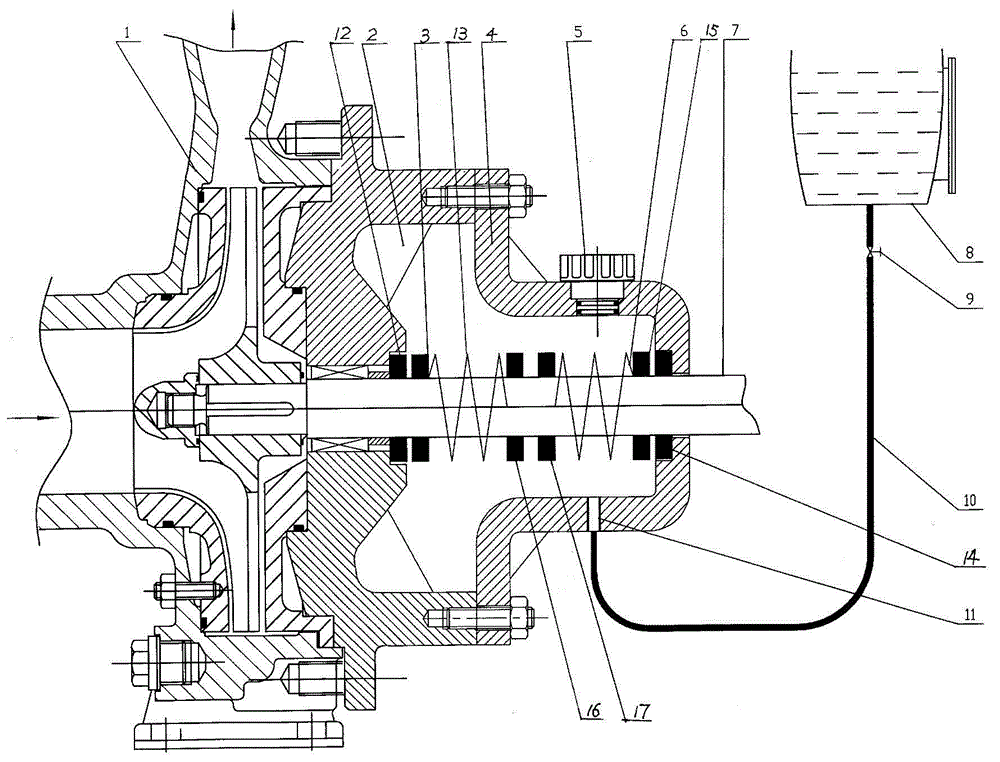

[0008] A circulation pump sealing structure under negative pressure / normal pressure, such as figure 1 As shown, a spring seat is fixed on the transmission shaft 7 in the sealed chamber 2 of the circulating pump 1, and the spring seat pushes the first moving ring 3 with the sealing ring through the first spring 13 to communicate with the first stationary ring 12 with the sealing ring. Cooperate, the transmission shaft 7 on the other side of the spring seat is provided with a spring seat to push the second moving ring 15 with a sealing ring through the second spring 6 to cooperate with the second static ring 14 with a sealing ring, and the second static ring 14 The sealing ring matches the concave platform on the shaft hole of the pump cover 4 in the sealing chamber. The pump cover 4 is a barrel-shaped gland with a connecting flange, and an oil inlet hole 11 is arranged on the lower part of the barrel surface of the pump cover 4. The oil outlet at the bottom of the high-level oi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com