Lifting mechanism

A lifting mechanism and lifting rod technology, which is applied in the direction of supporting machines, mechanical equipment, machine platforms/supports, etc., can solve the problems of inability to solve flexible detection, no lifting mechanism, etc., to achieve flexible movements, stable and reliable lifting and recovery , small size effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

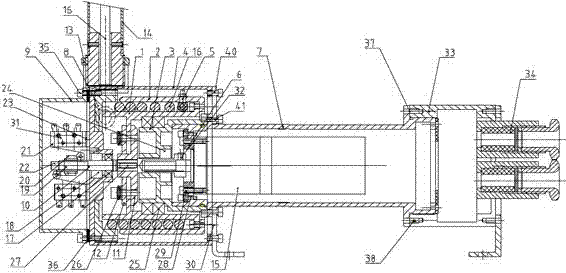

[0038] The technical solutions of the present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments.

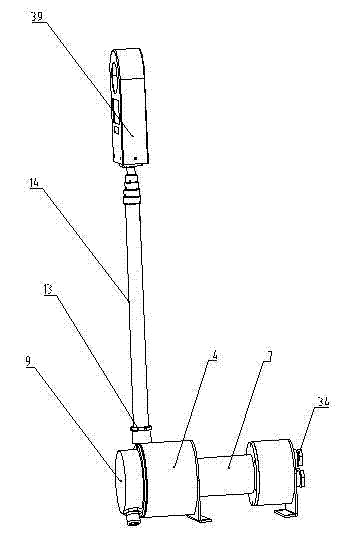

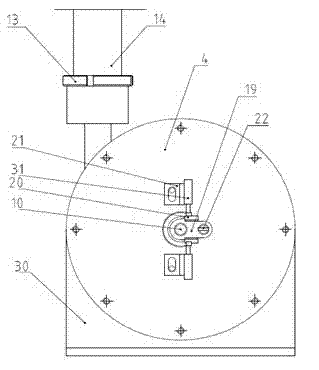

[0039] In a preferred embodiment of the present invention, a novel lifting mechanism with small volume and flexible movements is provided. attached figure 1 describes this lifting mechanism as figure 1 As shown, the lifting mechanism includes a head, a main cavity, and a tail. Specifically, the head part is a wiring cavity, the main cavity is composed of a lifting rod and a casing cavity, and the casing cavity includes a flameproof cavity, and the tail part is composed of a control panel cavity.

[0040] The head part and the main cavity are fastened and connected by a fastening device 35, and the connection methods include but are not limited to bolts, pins, screws and the like. Preferably, the fastening device 35 is a hexagon socket head cap screw 35 . More preferably, the connection between the head part and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com