A device and method for precise measurement of curved surface shape without an actuator

A technology of precision measurement and actuator, applied in measurement devices, optical devices, instruments, etc., can solve the problems of measurement speed influence, deformation, influence measurement accuracy, etc., to achieve high measurement accuracy, fast measurement speed, and avoid lighting angles. poor effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment 1

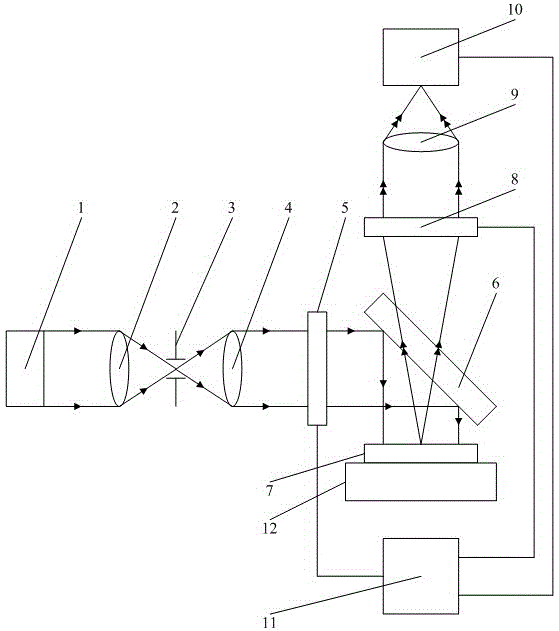

[0024] Such as figure 1 As shown, the curved surface shape precision measurement device includes a multi-angle illumination optical path and a curved surface shape measurement optical path;

[0025] The multi-angle illumination optical path is placed in sequence along the direction of light propagation: light source (1), condenser lens (2), pinhole (3), collimator lens (4), transmissive liquid crystal spatial light modulator (5), light splitter The prism (6) and the sample to be measured (7); the condenser lens (2) converges the beam emitted by the light source (1) on the pinhole (3), and the beam emitted from the pinhole (3) passes through the collimating lens (4) After collimation, it enters the transmissive liquid crystal spatial light modulator 1 (5) in parallel, is modulated by the transmissive liquid crystal spatial light modulator 1 (5), emits in parallel, and is reflected by the dichroic prism (6) to irradiate the sample in parallel (7) surface;

[0026] The optical ...

specific Embodiment 2

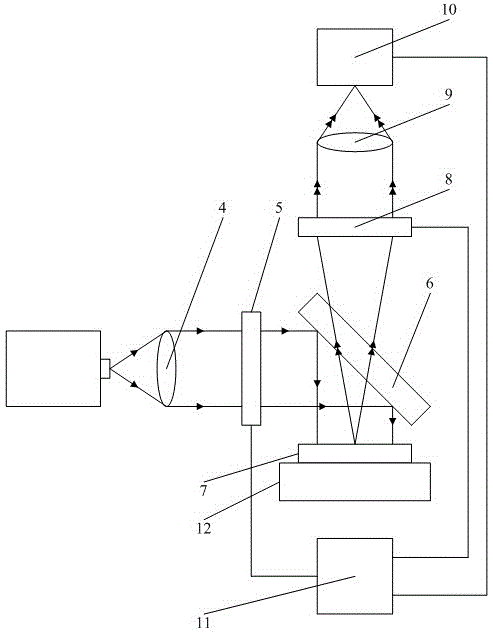

[0033] Such as figure 2 As shown, the curved surface shape precision measurement device includes a multi-angle illumination optical path and a curved surface shape measurement optical path;

[0034] The multi-angle illumination optical path is placed in sequence along the direction of light propagation: an ideal point light source, a collimator lens (4), a transmissive liquid crystal spatial light modulator (5), a dichroic prism (6) and a tested sample (7), The light beam emitted by the ideal point light source is collimated by the collimator lens (4), and then incident on the transmissive liquid crystal spatial light modulator one (5) in parallel, modulated by the transmissive liquid crystal spatial light modulator one (5), and exits in parallel. The spectroscopic prism (6) reflects and irradiates the surface of the tested sample (7) in parallel;

[0035] The optical path of the curved surface shape measurement is placed sequentially along the light propagation direction wi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com