Cone angle measuring device and method for axicons

The technology of a detection device and detection method is applied in the field of optical detection to achieve the effects of easy detection operation and simple structure of the device

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

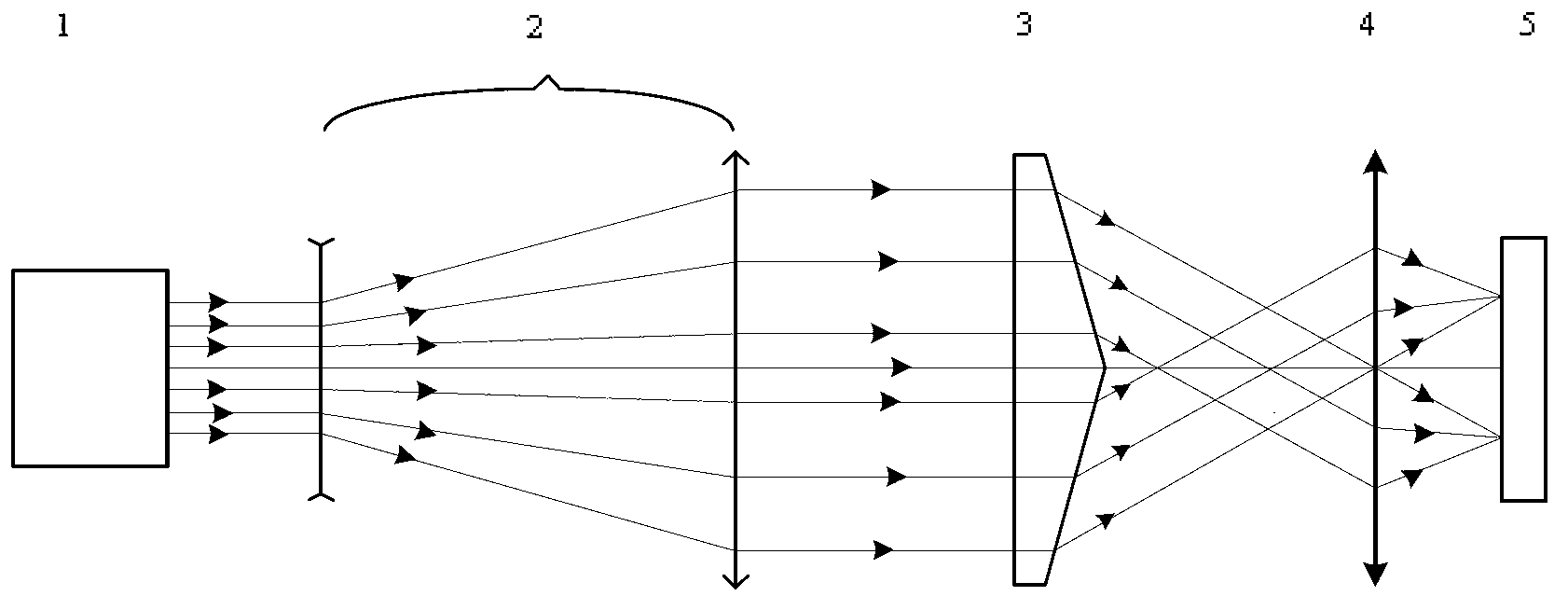

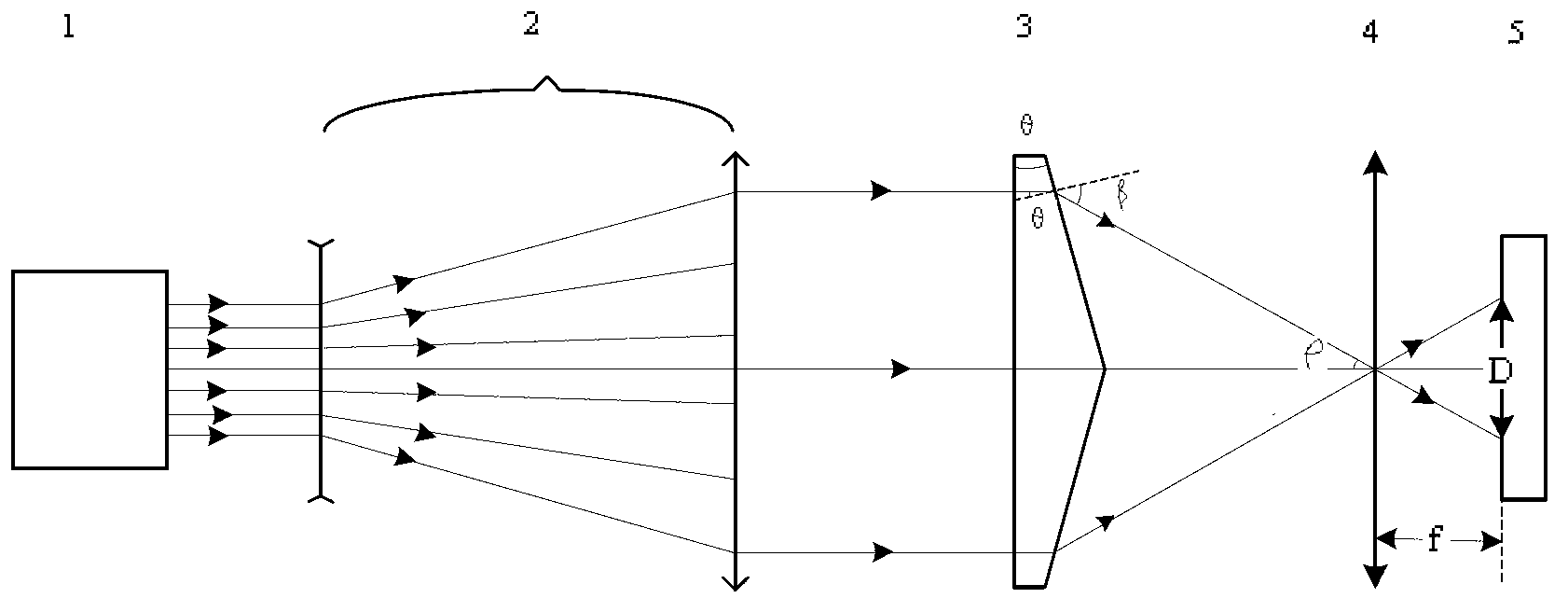

[0035] figure 2 The optical path diagram of measuring the convex axicon for the axicon cone angle detection device of the present invention, as can be seen from the figure, the axicon 3 to be measured in embodiment 1 of the present invention is a convex axicon, and the step of measuring the cone angle of the convex axicon as follows:

[0036] ① An axicon lens 3 to be measured is placed between the beam expander lens group 2 and the focusing lens 4 in the direction of the beam output of the laser 1, and the plane of the axicon lens 3 to be measured faces the light output direction of the laser 1;

[0037] ②Adjust the optical path: adjust the central axis of the beam expander group 2 to coincide with the central axis of the outgoing beam of the laser 1; adjust the plane of the axicon 3 to be measured to be perpendicular to the outgoing beam of the laser 1 , while ensuring that the central axis of the axicon 3 to be measured coincides with the central axis of the laser 1 outgoi...

Embodiment 2

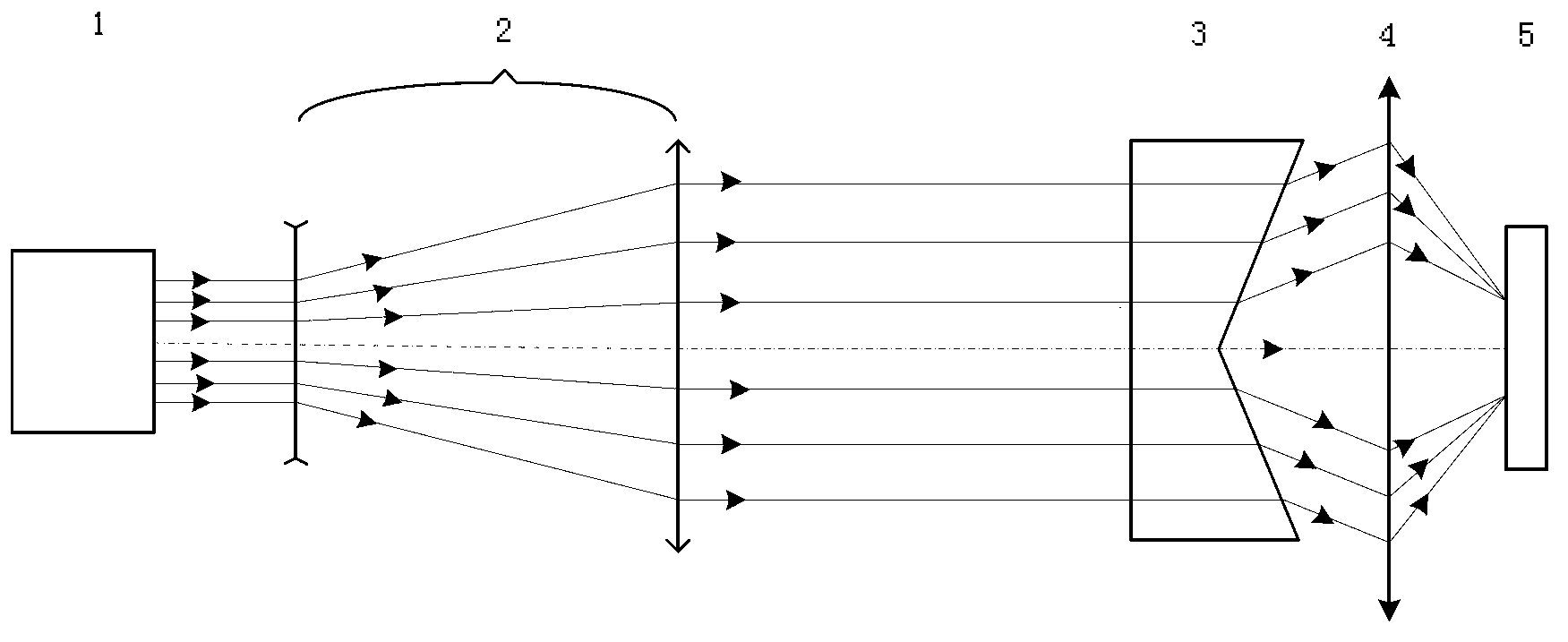

[0050] Figure 4 It is the optical path diagram of the concave axicon that is measured by the axicon cone angle detection device of the present invention. As can be seen from the figure, the axicon 3 to be measured in Embodiment 2 of the present invention is a concave axicon, and the step of measuring the cone angle of the concave axicon as follows:

[0051] ① An axicon lens 3 to be measured is placed between the beam expander lens group 2 and the focusing lens 4 in the direction of the beam output of the laser 1, and the plane of the axicon lens 3 to be measured faces the light output direction of the laser 1;

[0052] ②Adjust the optical path: adjust the central axis of the beam expander group 2 to coincide with the central axis of the outgoing beam of the laser 1; adjust the plane of the axicon 3 to be measured to be perpendicular to the outgoing beam of the laser 1 , while ensuring that the central axis of the axicon 3 to be measured coincides with the central axis of the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com