tire testing machine

A testing machine and tire technology, applied in the field of machinery, can solve the problems of engineering tire strength, imprint, vertical stiffness and subsidence without special testing equipment.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

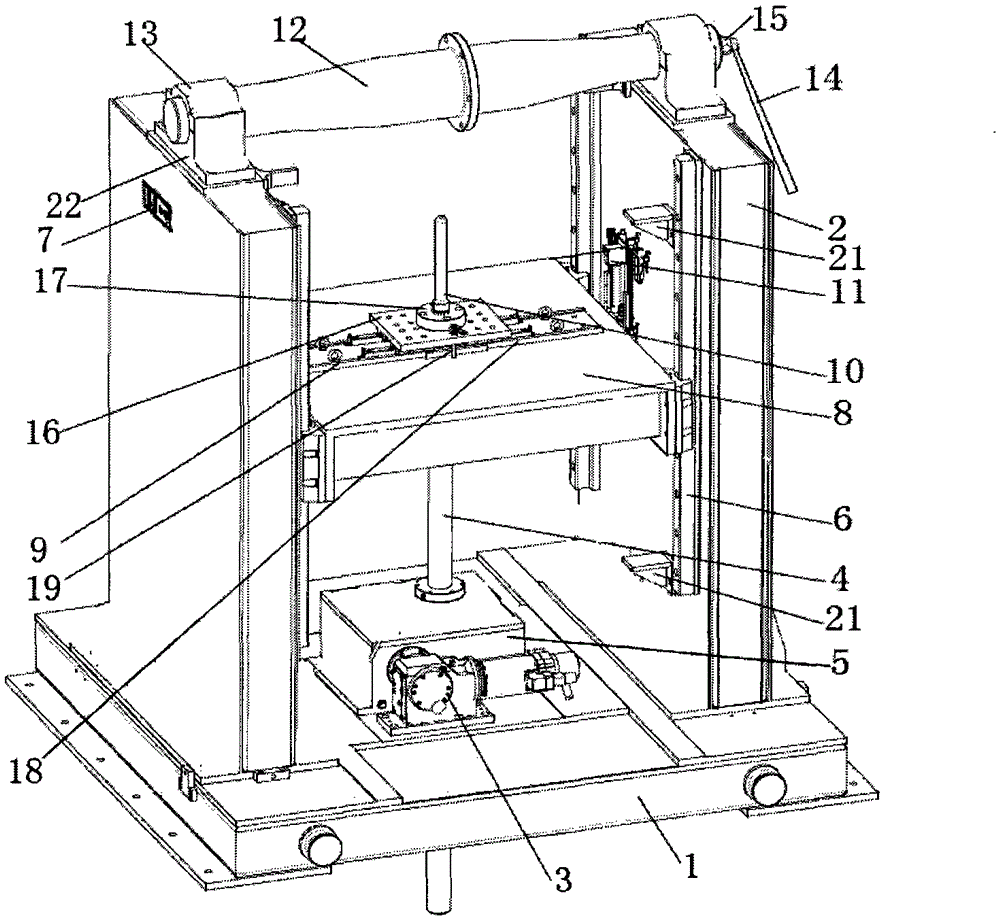

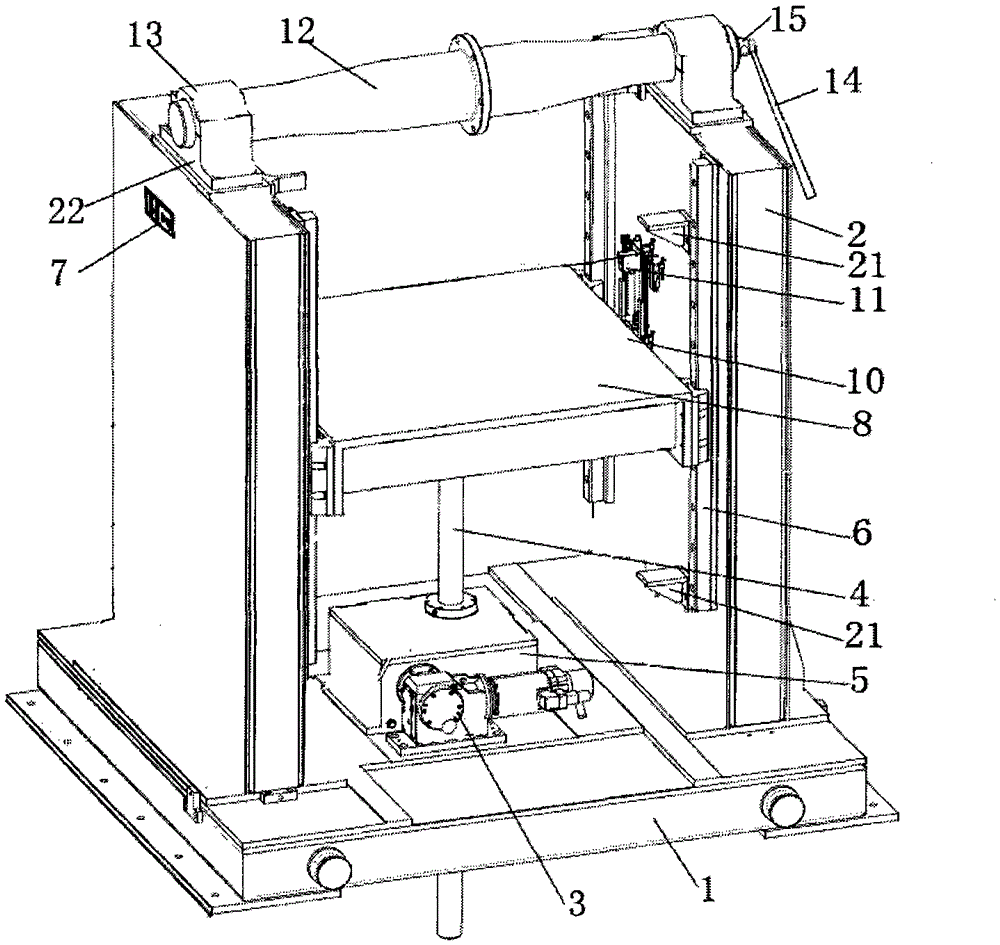

[0030] The tire testing machine in the present embodiment is used for static load and vertical rigidity experiment of tire.

[0031] Such as figure 2 with Figure 4 As shown, the tire testing machine includes a fixing device, a testing device, and a control device. The testing device is driven by a loading device to load the tire on the fixing device.

[0032] The loading device includes a servo motor 3, a reducer 5 connected to the servo motor 3, and a ball screw 4 connected to the reducer 5. The ball screw 4 is installed in the output hollow shaft of the reducer 5 through its nut and connected by a flange.

[0033] The fixing device includes a base 1, two vertical walls 2 perpendicular to the base 1, and a rim fixing device between the two vertical walls 2; the vertical walls 2 are parallel to each other, and there are longitudinal linear guide rails 6 parallel to each other inside.

[0034] The rim fixing device spans the tops of the two vertical walls 2;

[0035] The f...

Embodiment 2

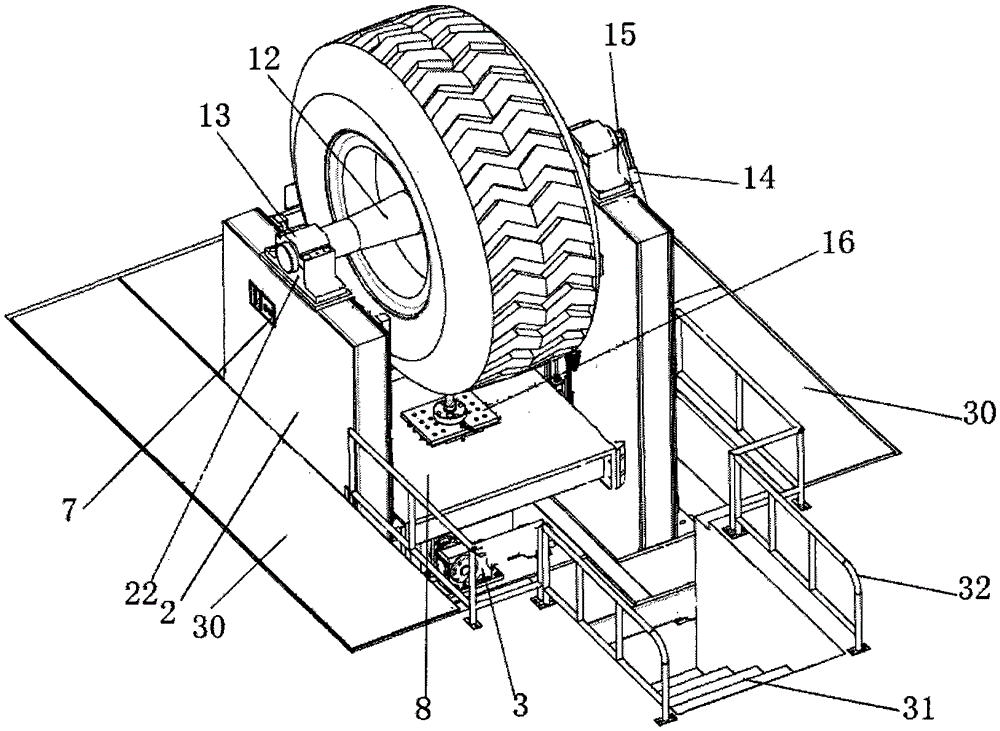

[0046] The tire testing machine in the present embodiment is used for static load and impression test of tire.

[0047] Such as figure 2 with Figure 5 As shown, the tire testing machine includes a fixing device, a testing device, and a control device. The testing device is driven by a loading device to load the tire on the fixing device.

[0048] The loading device includes a servo motor 3, a reducer 5 connected to the servo motor 3, and a ball screw 4 connected to the reducer 5. The ball screw 4 is installed in the output hollow shaft of the reducer 5 through its nut and connected by a flange.

[0049] The fixing device includes a base 1, two vertical walls 2 perpendicular to the base 1, and a rim fixing device between the two vertical walls 2; the vertical walls 2 are parallel to each other, and there are longitudinal linear guide rails 6 parallel to each other inside.

[0050] The rim fixing device spans the tops of the two vertical walls 2;

[0051] The fixing part in...

Embodiment 3

[0063] The tire testing machine in this embodiment is used for static load and sidewall deformation experiments of tires.

[0064] Such as figure 2 with Figure 4 As shown, the tire testing machine includes a fixing device, a testing device, and a control device. The testing device is driven by a loading device to load the tire on the fixing device.

[0065] The loading device includes a servo motor 3, a reducer 5 connected to the servo motor 3, and a ball screw 4 connected to the reducer 5. The ball screw 4 is installed in the output hollow shaft of the reducer 5 through its nut and connected by a flange.

[0066] The fixing device includes a base 1, two vertical walls 2 perpendicular to the base 1, and a rim fixing device between the two vertical walls 2; the vertical walls 2 are parallel to each other, and there are longitudinal linear guide rails 6 parallel to each other inside.

[0067] The rim fixing device spans the tops of the two vertical walls 2;

[0068] The fix...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com