Easy-to-tear anti-fake ultrahigh-frequency RFID (radio frequency identification) tag and production method thereof

A technology of RFID tags and manufacturing methods, applied in the direction of recording carriers used in machines, instruments, computer components, etc., can solve problems such as unstable performance, high scrap rate, high manufacturing cost, etc., and achieve high finished product pass rate and finished product pass rate Improvement and low manufacturing cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0043] The technical solutions of the present invention will be further described below in conjunction with the accompanying drawings and through preferred embodiments.

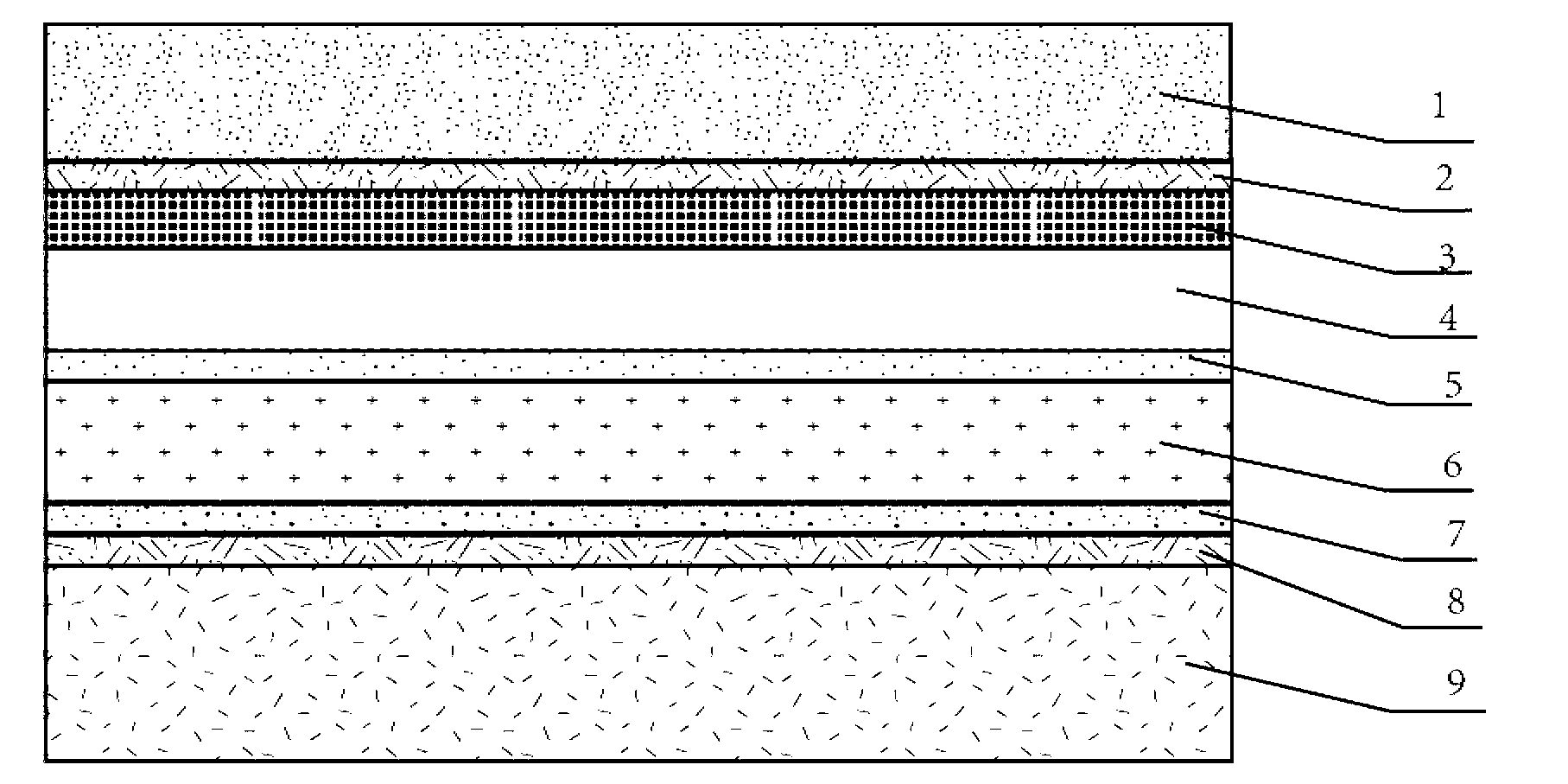

[0044] like figure 1 As shown, in this embodiment, an easy-to-tear anti-counterfeit UHF RFID label, the label structure is as follows: easy-to-break layer 1, first self-adhesive layer 2, electronic chip layer 3, antenna circuit layer 4, dry compound Process adhesive layer 5, antenna film substrate layer 6, adhesive layer 7, second self-adhesive layer 8, backing paper layer 9, and one side of the fragile layer 1 is bonded with electrons through the first self-adhesive layer 2 One side of the chip layer 3, the other side of the electronic chip layer 3 is compounded with one side of the antenna circuit layer 4; The other side of the bottom is bonded with the backing paper layer 9 through the adhesive layer 7 and the second self-adhesive layer 8 successively.

[0045] The destructible layer 1 is made of materia...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Depth | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com