Lithium ion battery

A lithium-ion battery and cell technology, applied in secondary batteries, battery components, circuits, etc., can solve disadvantages and other problems, achieve timely response, improve safety performance, and ensure safety performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

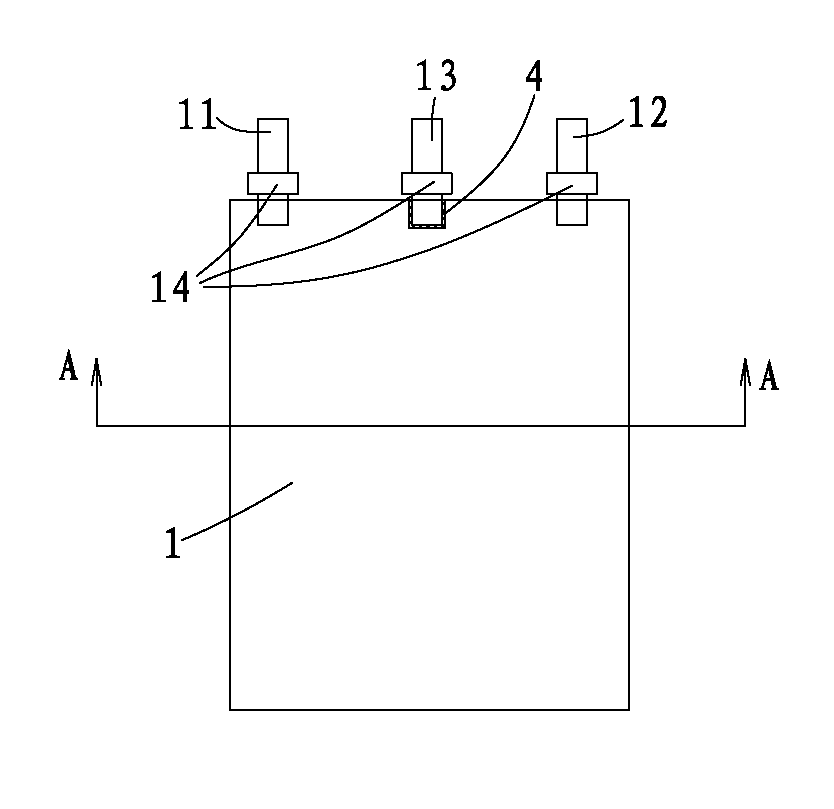

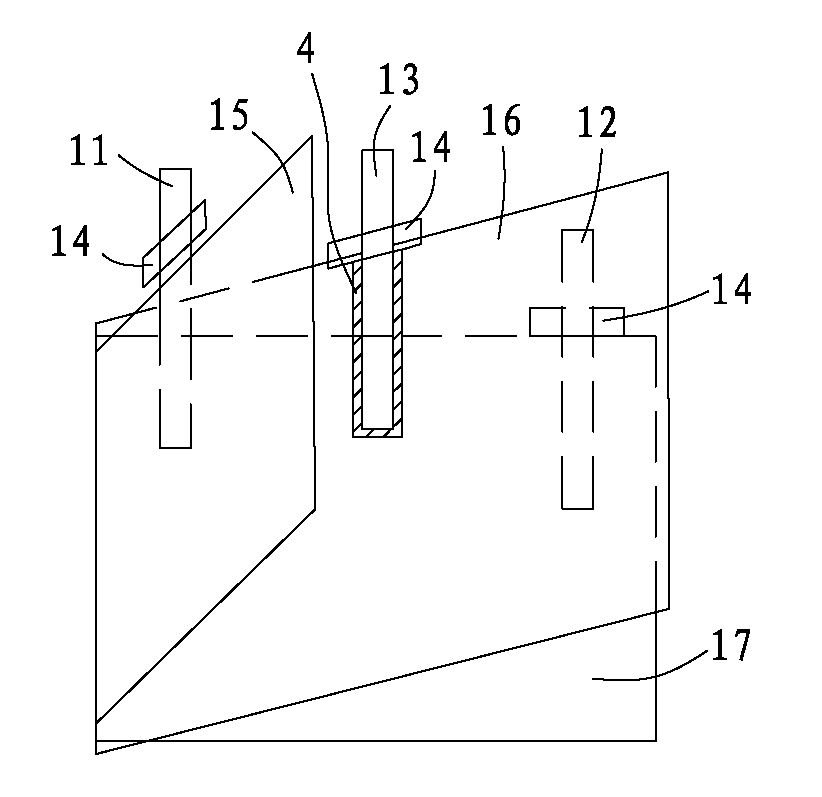

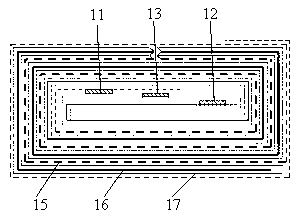

[0021] Example 1, Such as Figure 1~5 As shown, a lithium-ion battery includes a packaging bag, a battery cell 1 contained in the packaging bag, a thermal fuse 3 arranged on the surface of the battery cell 1, and an electrolyte poured into the packaging bag. The battery cell 1 includes a positive electrode diaphragm 15. The negative electrode diaphragm 17 and the separator 16 arranged between the positive electrode diaphragm 15 and the negative electrode diaphragm 17, the front end of the cell 1 is provided with a positive electrode tab 11 and a negative electrode tab 12, and the front end of the cell 1 is also provided with a The safety tab 13 is in contact with the thermal fuse 3 , and the safety tab 13 is arranged at the positive tab 11 of the battery cell 1 .

[0022] Preferably, the temperature fuse 3 is provided with a temperature sensing device 31 .

[0023] One end of the safety tab 13 is located inside the cell 1 and fixed to the isolation film 16, and the other en...

Embodiment 2

[0027] Example 2, The difference from Embodiment 1 is that the material of the safety tab 13 in this embodiment is Ni, and the safety tab 13 is arranged at the negative tab 12 of the battery cell 1 .

[0028] Others are the same as in Embodiment 1 and will not be repeated here.

Embodiment 3

[0029] Example 3, The difference from Embodiment 2 is that the material of the safety tab 13 in this embodiment is Cu, and the safety tab 13 is arranged at the center of the battery cell 1 .

[0030] Others are the same as in Embodiment 2 and will not be repeated here.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com