Method and device for separating disk-shaped elements which adhere to each other

A component, disc-shaped technology, applied in the field of separating two disc-shaped components attached to each other, can solve problems such as process interruption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

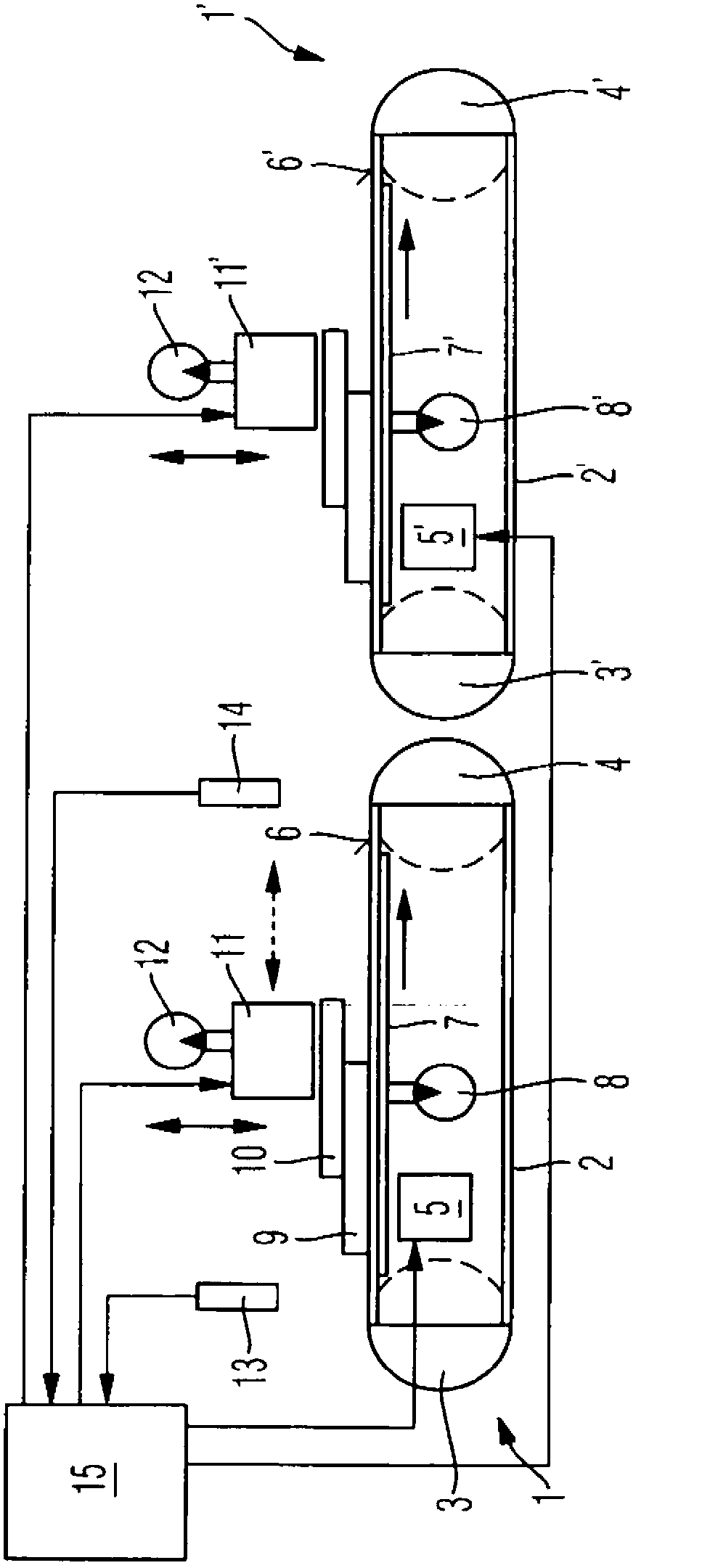

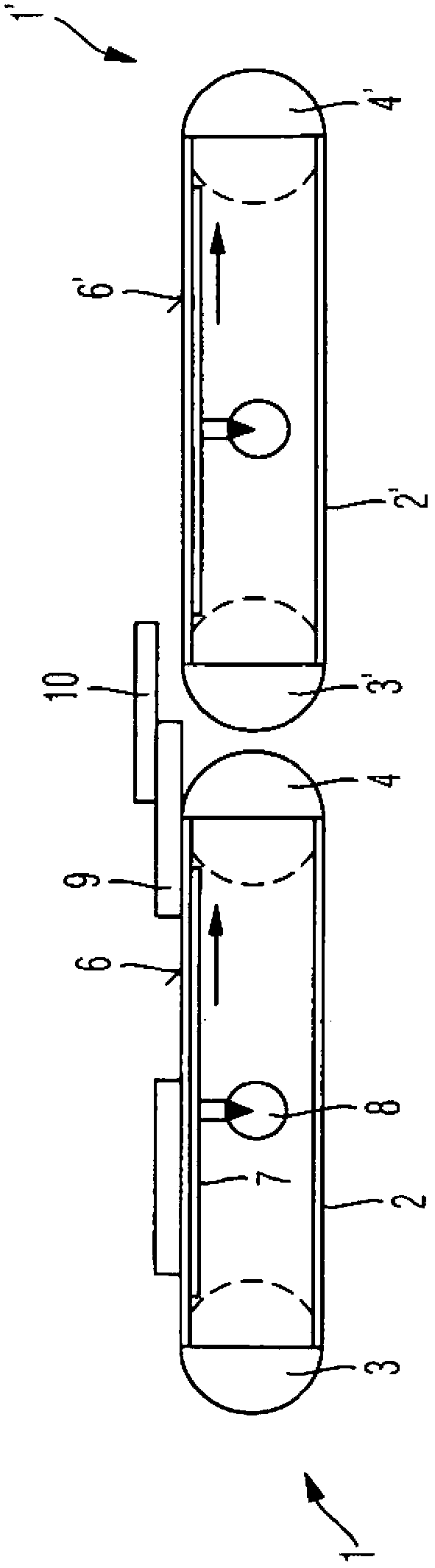

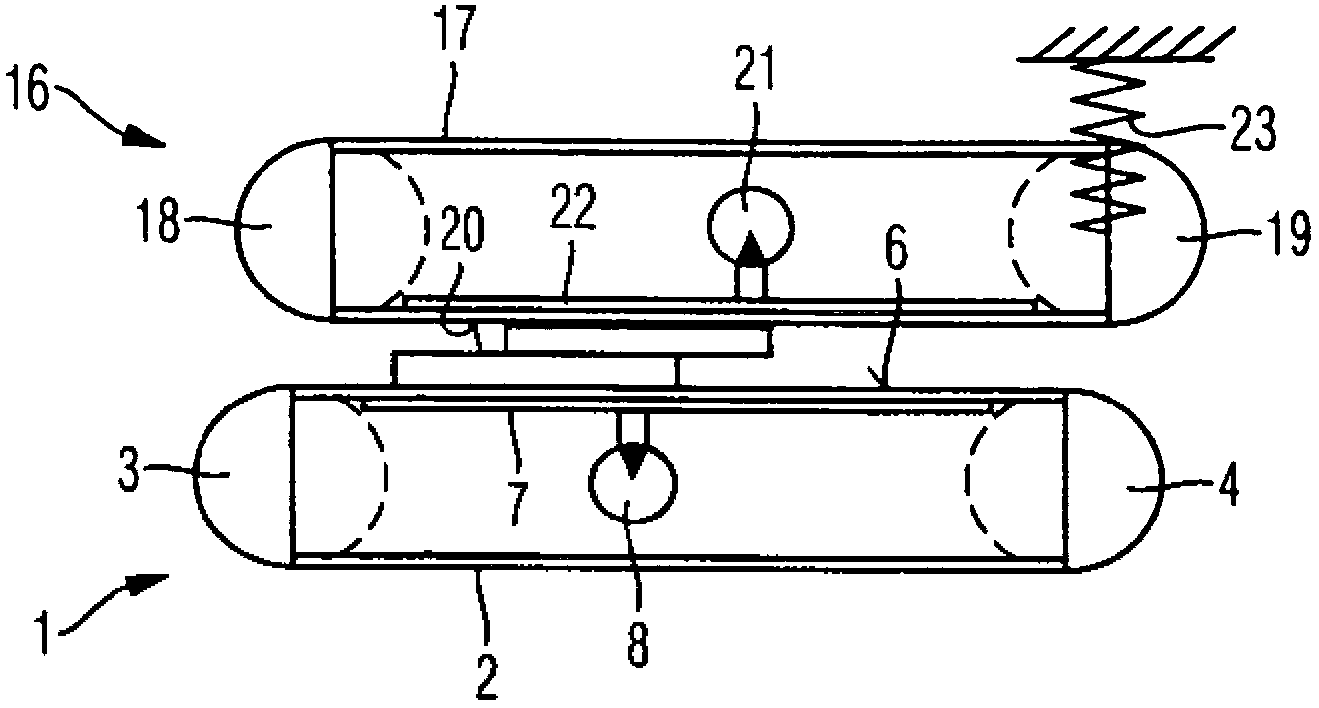

[0019] figure 1 A two-stage subsequent separation apparatus is shown. Refer below figure 1 Elements explained for detecting wafers attached to each other and for controlling the drive mechanism are also presented in figure 2 and image 3 in the device. However, to keep the drawings simple, full representations have not been repeated.

[0020] The device for separating mutually adhering disc-like elements comprises a first transfer device 1 . The first conveyor device 1 is preferably embodied as a conveyor belt. The conveyor belt provides a belt 2 which is formed in a loop and runs over a first drive roller 3 and a second drive roller 4 . A drive mechanism 5 acting on at least the first drive roller 3 or the second drive roller 4 is provided for driving the conveyor belt. The drive mechanism 5 can be adjusted with respect to the transport speed of the belt 2 .

[0021] On its outwardly facing side, the belt 2 forms a conveying plane 6 . The side of the belt 2 facing a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com