Parasitic protozoon lyophilized powder and preparation method thereof

A technology for freeze-dried powder and protozoa, which is applied in the fields of cryogenic biology and biomedicine, and achieves the effects of easy long-term storage, short drying time and stable properties.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

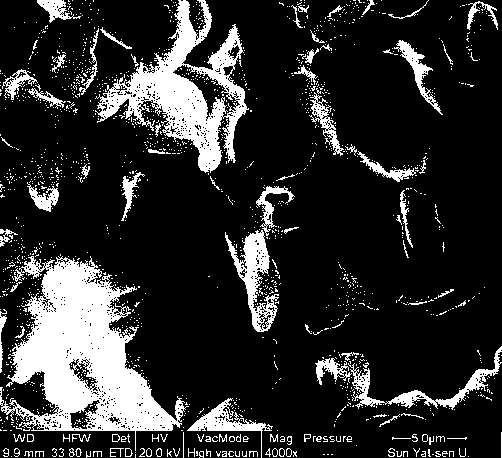

Image

Examples

Embodiment 1

[0026] Weigh trehalose and tea polyphenols, dissolve them in PBS buffer, and prepare a freeze-drying protectant solution. The concentration of trehalose is 0.4 mol / L, and the concentration of tea polyphenols is 0.2 mol / L. Store in a refrigerator at 4°C for later use. in. Arterial blood was collected from the heart of mice infected with Trypanosoma brucei for later use. The mouse blood containing trypanosomiasis and the lyoprotectant solution were fully mixed at a volume ratio of 1:1 to make a trypanosomiasis suspension, which was divided into 2.5ml vials with a volume of 0.2ml of trypanosomiasis suspension. After incubating at room temperature for 5 minutes, put them directly into liquid nitrogen for pre-freezing. After 24 hours, the pre-frozen trypanosome suspension was transferred together with the vial to a freeze dryer for vacuum drying to finally obtain a freeze-dried powder of parasitic protozoa. The vacuum drying conditions are as follows: drying pressure 10 Pa, separ...

Embodiment 2

[0028] Weigh trehalose and tea polyphenols, dissolve them in PBS buffer, and prepare a lyoprotectant solution with a trehalose concentration of 0.1 mol / L, and store them in a 4°C refrigerator for later use. Arterial blood was collected from the heart of mice infected with Plasmodium and collected for later use. Mix the blood of mice containing malaria parasites and the lyoprotectant solution at a volume ratio of 1:1 to make a trypanosomal suspension, and distribute them in 2.5ml vials with a volume of 0.2ml of malaria parasite suspension. After incubating at room temperature for 10 minutes, put them directly into liquid nitrogen for pre-freezing. After 24 hours, transfer the pre-frozen malaria parasite suspension together with the vial to a freeze dryer for vacuum drying to finally obtain a parasite freeze-dried powder. The vacuum drying conditions are as follows: drying pressure 20 Pa, separator temperature -30°C, cold trap temperature -180°C, and drying time 100 minutes. B...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com