Sole with novel bulge structure

A hollow structure, bottom surface technology, applied in the direction of soles, footwear, applications, etc., can solve the problems of insufficient, small contact area, easy to break air flow space, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

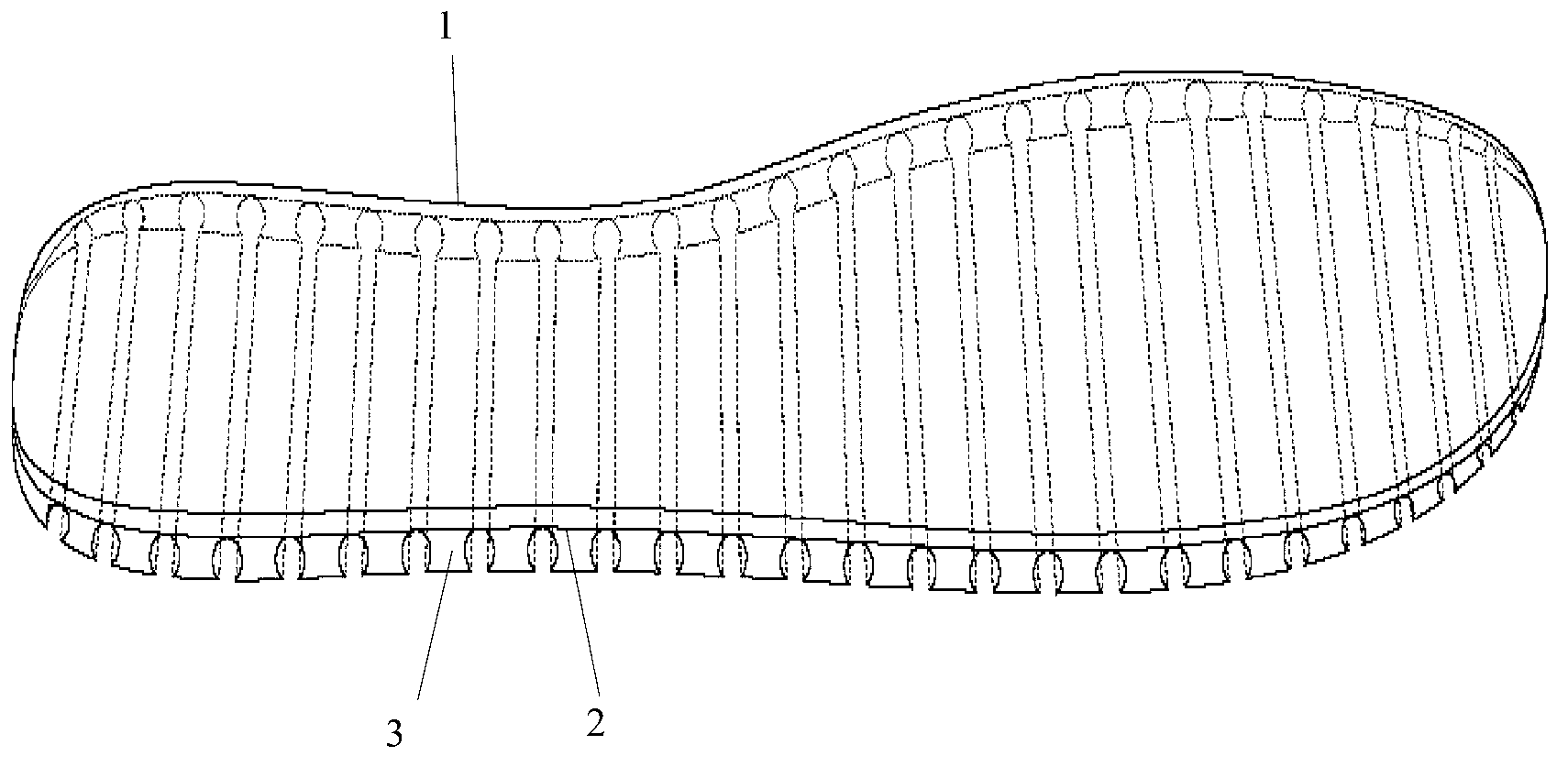

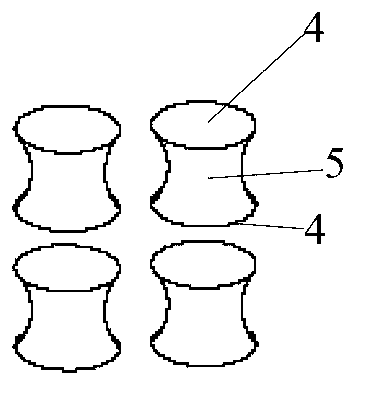

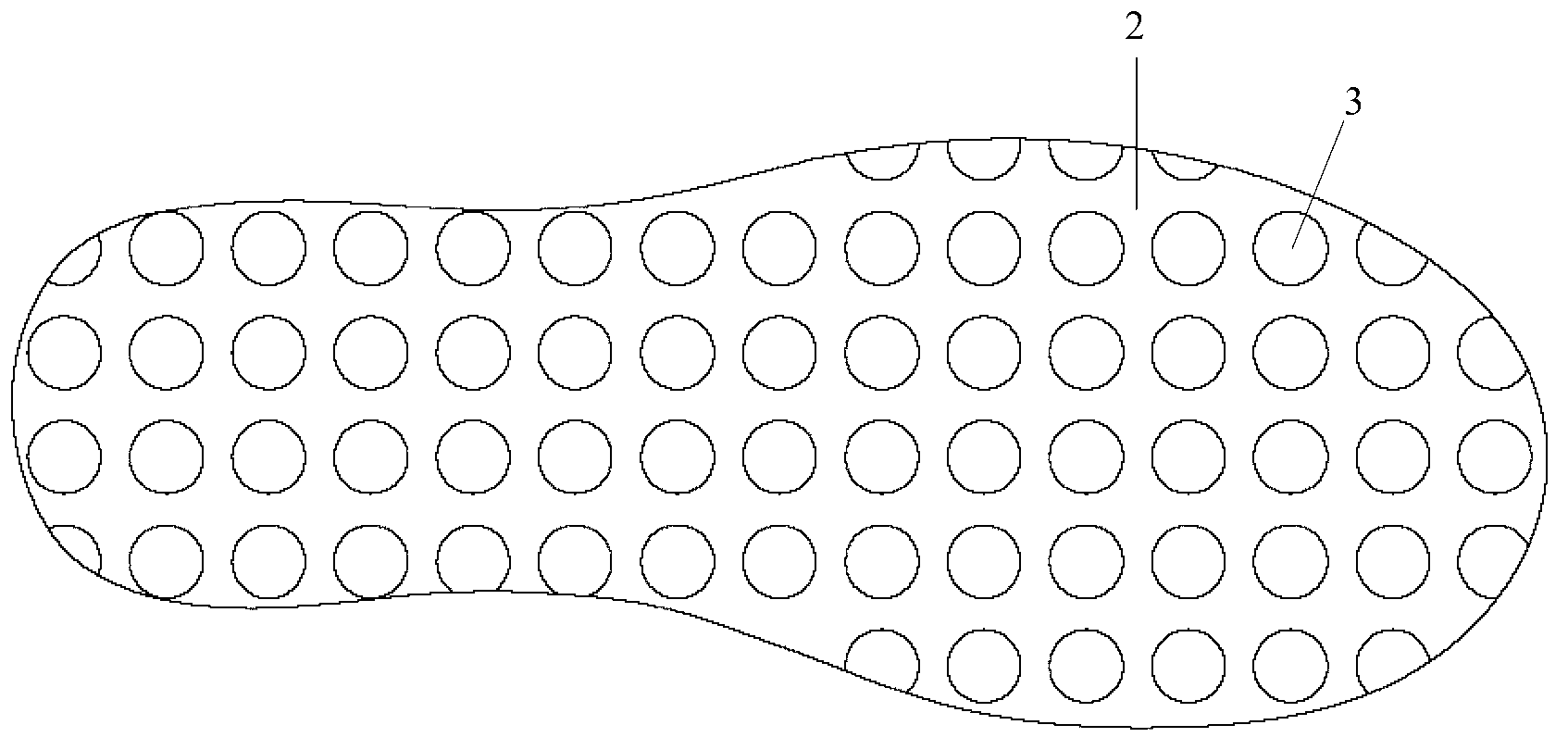

[0042] Such as figure 1 Shown is a schematic diagram of the sole. A sole 1, in figure 1 The shoe sole 1 is shown in , the bottom surface of the shoe sole 2 is provided with several protrusions 3 , and the projections 3 extend from the bottom surface of the shoe sole 2 to the bottom of the shoe sole 1 . Preferably, below the sole 1 here refers to directly below the sole 1; the extension direction of the protrusion 3 includes a contraction section (such as figure 2shown), preferably, the extension direction of the protrusion 3 is perpendicular or approximately perpendicular to the bottom surface of the sole 2, and the contraction section (such as figure 2 (shown) is a waist-like structure shrinking from both ends to the middle cross-sectional area on the extension path of the protrusion 3 . Such as figure 2 Shown is a schematic diagram of several contraction segments. exist figure 2 The two ends 4 of a constriction section and the middle part 5 of the constriction sect...

Embodiment 2

[0044] Such as figure 1 As shown, on the basis of the technical implementation of Example 1, this embodiment further proposes that the shrinkage section is the whole of the protrusion 3, and the shrinkage of the cross-sectional area is a gradual shrinkage of the cross-sectional area. Preferably, the gradual shrinkage can It is understood that the edge of the longitudinal section of the protrusion 3 along the extending direction of the protrusion 3 is a smooth curve.

Embodiment 3

[0046] Such as Figure 8 As shown, on the basis of Embodiment 1, this embodiment further increases air vents 7 on the sole 1, and the sole 1 has air vents 7, and the air vents 7 are arranged outside the protrusions 3 of the sole 1. Partially and through the upper and lower surfaces of the sole 1, because the bottom surface of the sole 2 is raised by the protrusion 3 (such as figure 1 As shown), it is basically possible to prevent sundries from scratching the soles of the feet through the ventilation holes 7, so the size of the ventilation holes 7 can be designed to be larger.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com