Oxidation tank with good aerating effect

An oxidation tank and aeration technology, applied in chemical instruments and methods, chemical/physical processes, chemical/physical/physical chemical processes, etc., can solve problems such as uneven material exchange, save aeration heads, enhance aeration Gas effect, beneficial to the effect of uniform mixing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

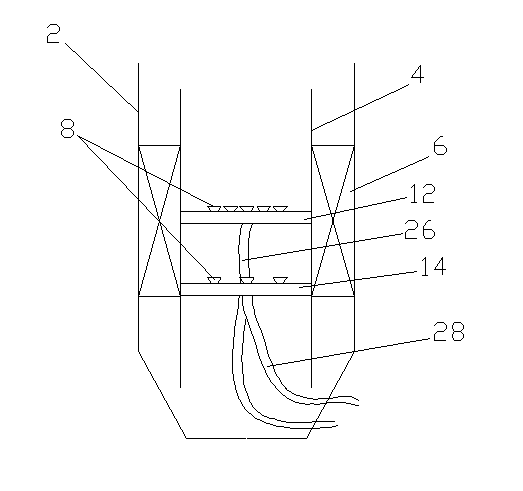

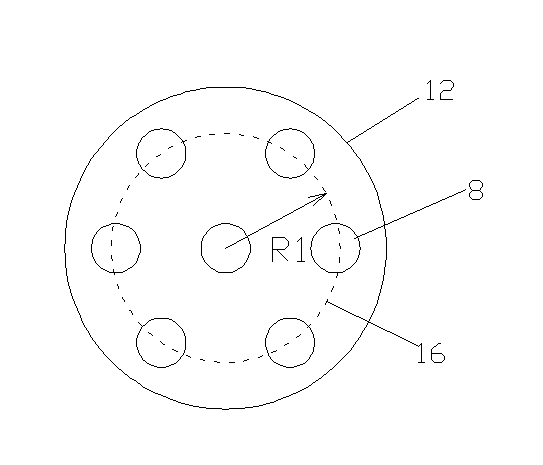

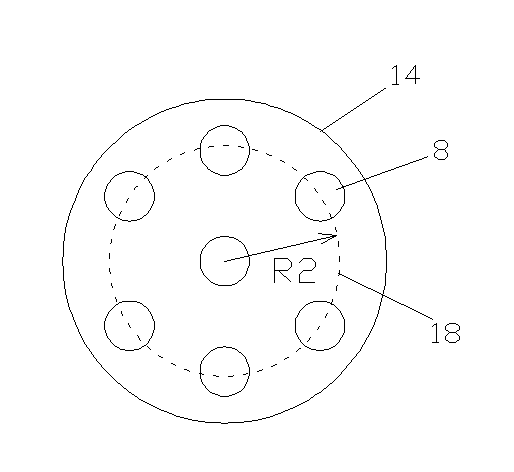

[0017] The present invention will now be described in further detail with reference to the drawings and embodiments. These drawings are simplified schematic diagrams, which only illustrate the basic structure of the present invention in a schematic manner, and therefore only show the constitutions related to the present invention.

[0018] Such as Figure 1-3 As shown, an oxidation tank with good aeration effect includes a hollow cylinder 2 with an open upper end and a diversion cylinder 4 with openings at both ends vertically arranged in the cylinder 2, and there is a gap between the cylinder 2 and the diversion cylinder 4 The gap is filled with filler 6, and the guide tube 4 is also provided with an aeration device. The aeration device includes a compressed air pipe and an aeration head 8 connected to the compressed air pipe. The aeration device also includes at least two vertical A plurality of aeration heads 8 are respectively arranged on the disc-shaped supports distributed ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com