Preparation method for standard sealant test piece

A sealant and test piece technology, applied in chemical instruments and methods, layered products, lamination devices, etc., can solve the problems of incomplete vulcanization, incomplete removal of test pieces, and long natural vulcanization cycle of sealants. Volatile effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

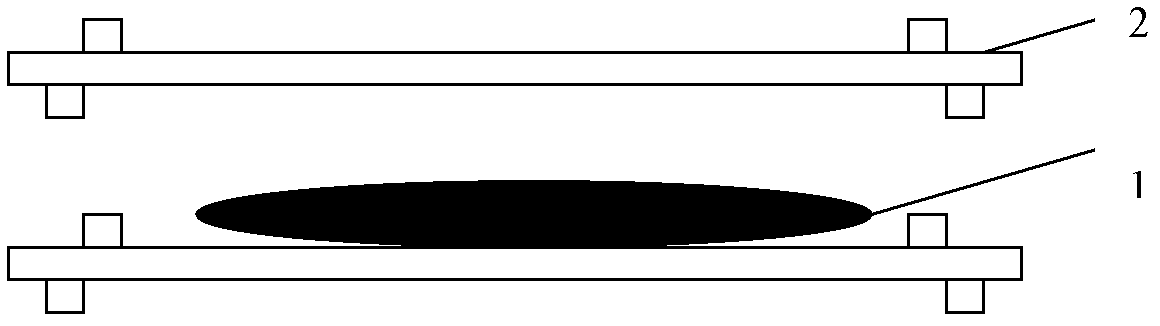

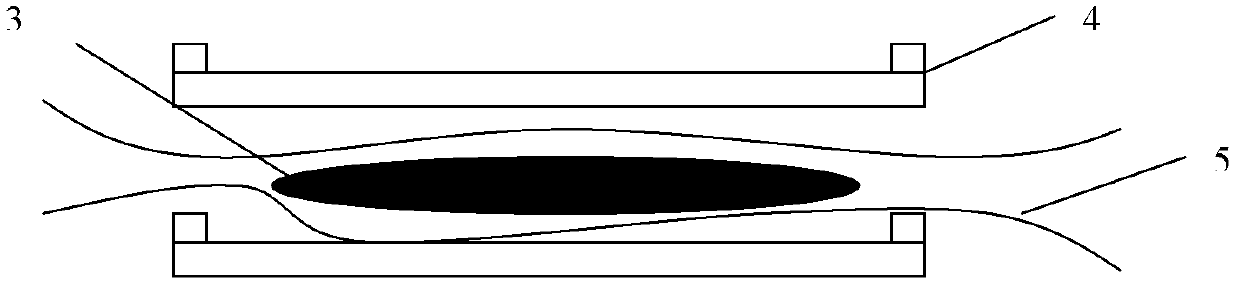

[0016] figure 2 Prepare the structural representation of the mold for the test piece of the present invention, wherein 3 is a sealant, 4 is a mold, and 5 is an anti-sticking film. A method for preparing a sealant standard test piece of the present invention includes:

[0017] S101, placing the sealant between two release films.

[0018] S102. Put the sealant together with the release film into the mold.

[0019] The anti-sticking film is made of polyvinyl chloride film, and the mold is made of steel. Place the kneaded sealant between two pieces of polyvinyl chloride film, put the sealant and polyvinyl chloride film together into a steel mold, and roughly flatten it with a small wooden stick. Fill the required number of steel templates according to the test items.

[0020] S103. Stack the molds equipped with sealant and anti-adhesive film layer by layer, put the steel cover plate on the top, and align the mold and the cover plate completely.

[0021] S104. Put the stacked ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com