Automotive transverse stabilizing device

A lateral stabilizing device and automobile technology, applied in vehicle components, transportation and packaging, interconnection systems, etc., can solve problems such as abnormal wear and tear of steering tires, and achieve the effect of solving the problem of maneuverability and abnormal wear of tires

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

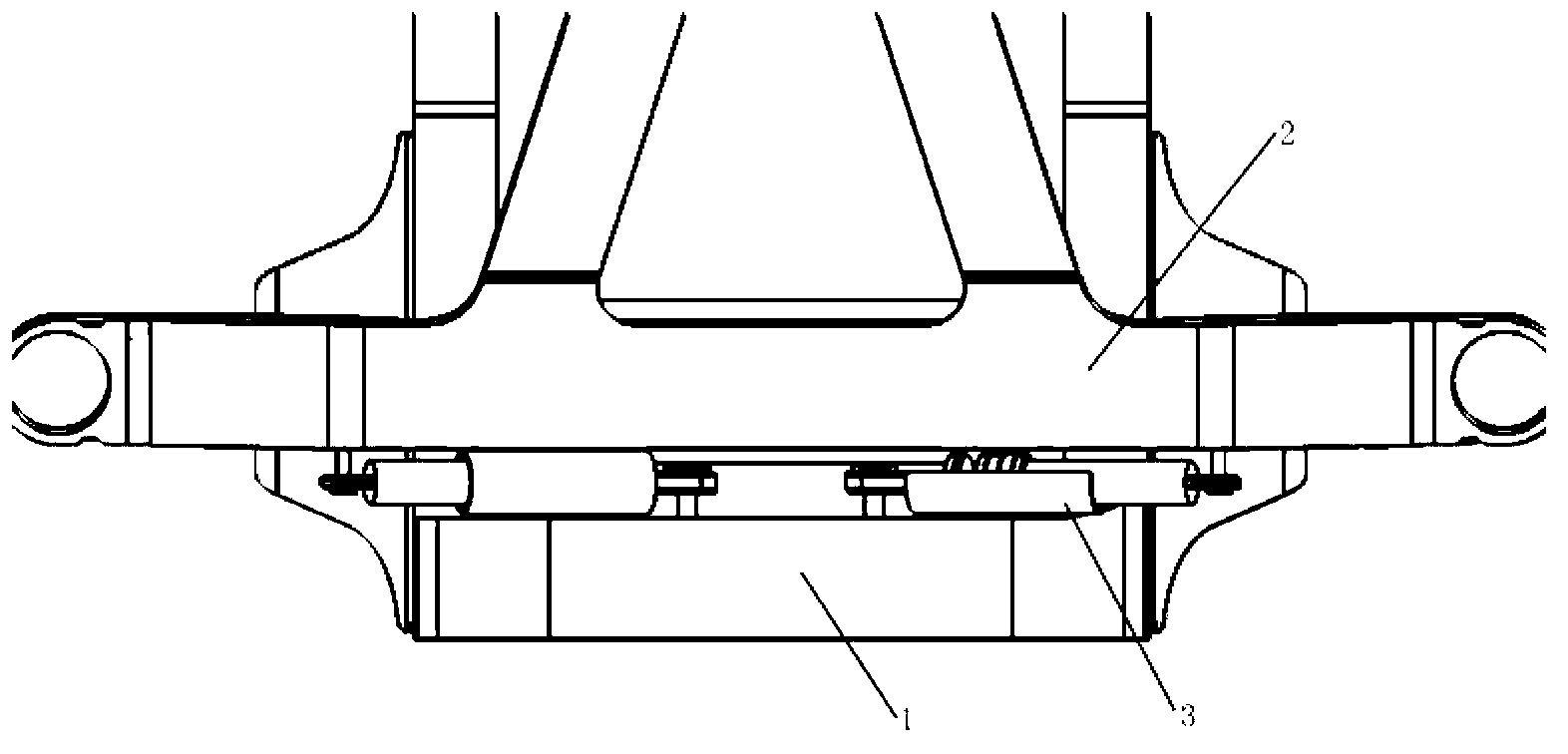

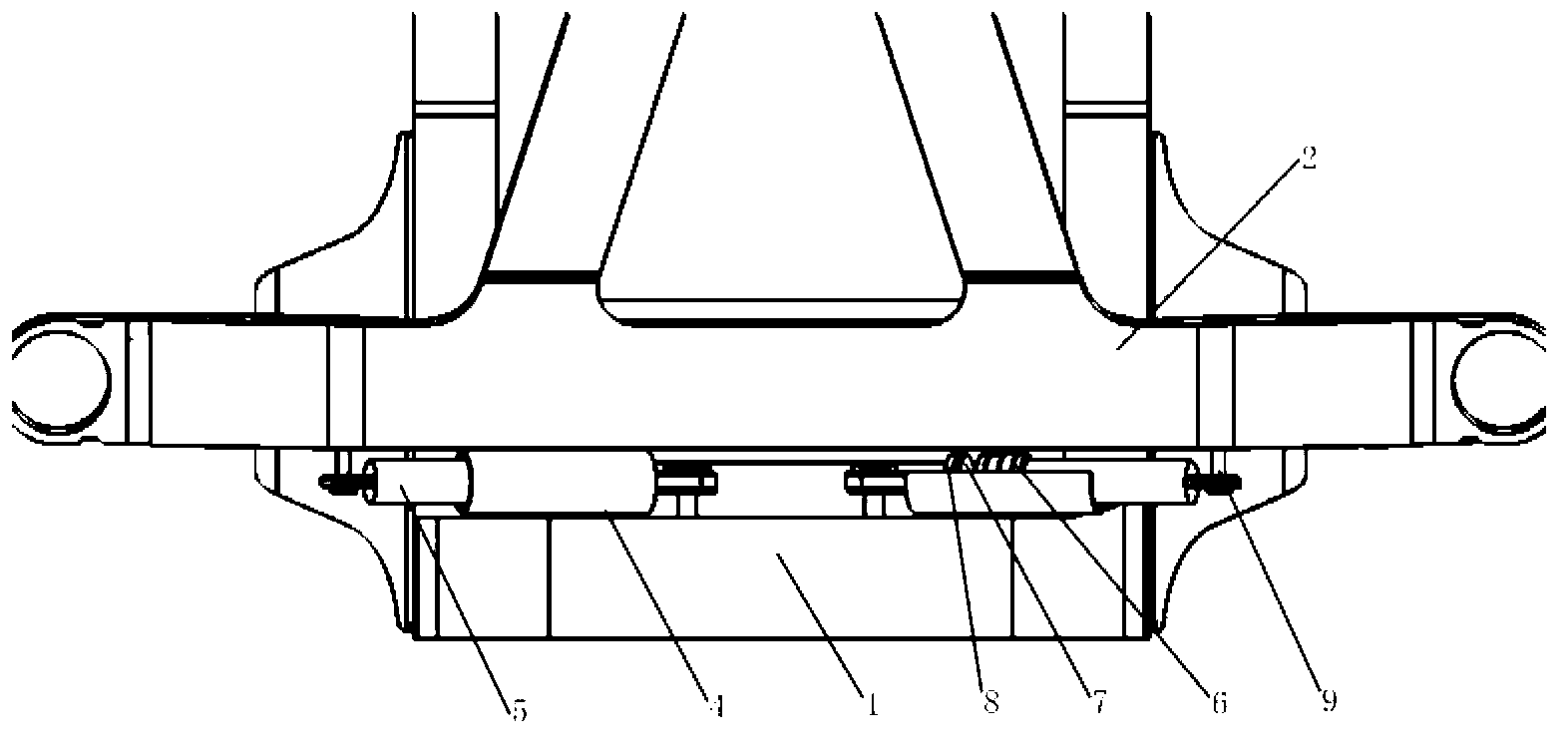

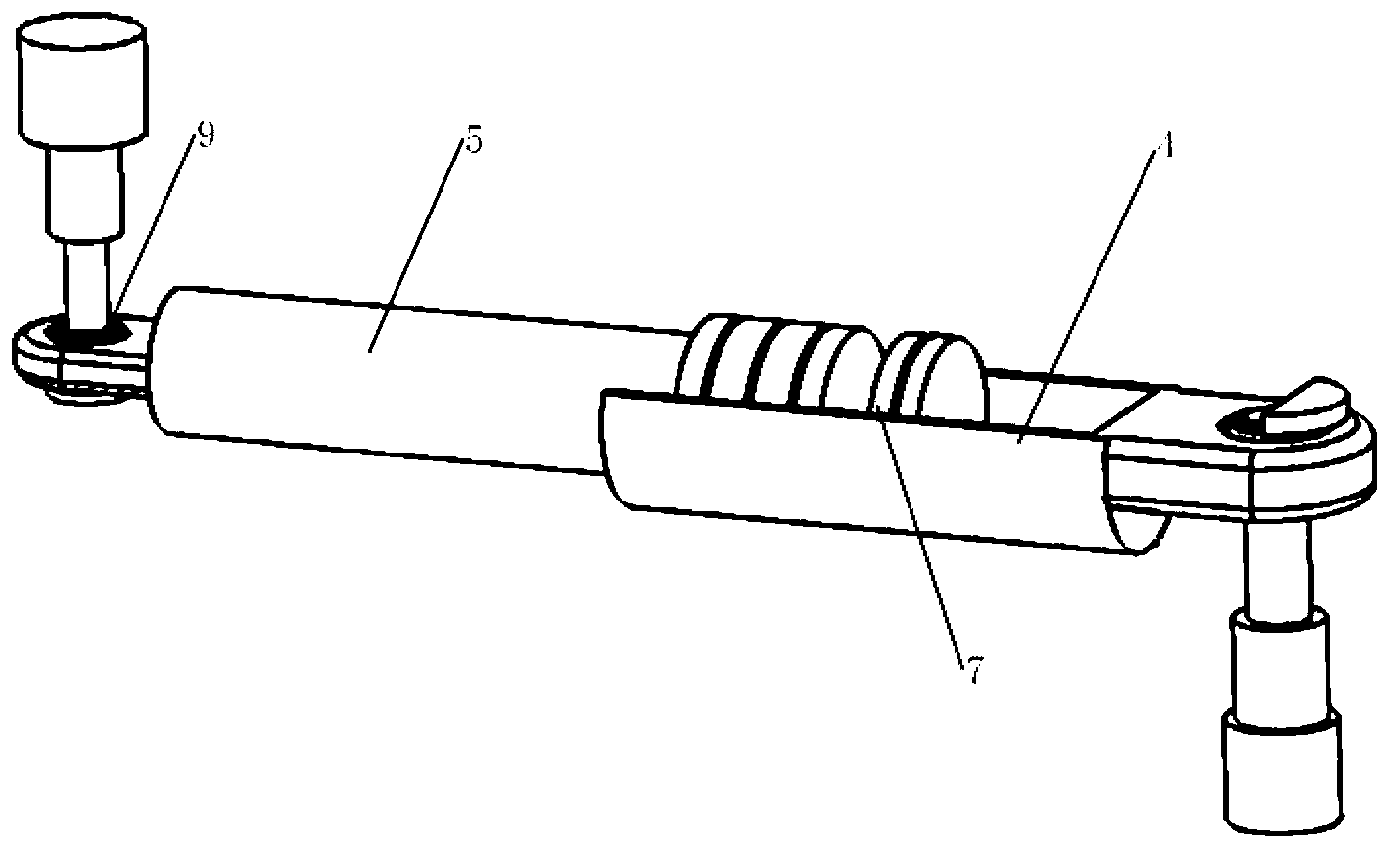

[0014] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments. see figure 1 , figure 2 with image 3 , two symmetrical lateral stabilizers 3 are installed between the vehicle frame 1 and the unsprung part 2. The structure of the lateral stabilizer is: the cylinder 4 is cylindrical and adopts a casting machining structure. The external dimensions of the cylinder 4 and the internal structure size can be obtained from the actual tonnage and installation space of the vehicle; the rod barrel 5 is cylindrical and adopts a casting machining structure, and the structure and quantity arrangement of the seal ring 6 at the head of the rod barrel can be calculated according to the actual tonnage of the vehicle. Design, the structural size of the rod barrel can be obtained according to the structural size of the cylinder barrel and the actual installation space; the floating piston 7 is cylindrical and adopts a castin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com