Anti-blocking controllable negative pressure quick solidifying method for flow state dredging silt

A technology of dredging silt and negative pressure, which is applied in waterway engineering and water conservancy fields, can solve problems such as poor silt effect and blockage of drainage channels, and achieve the effects of shortening the cycle of recovery and utilization, saving power consumption, and shortening the construction period

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

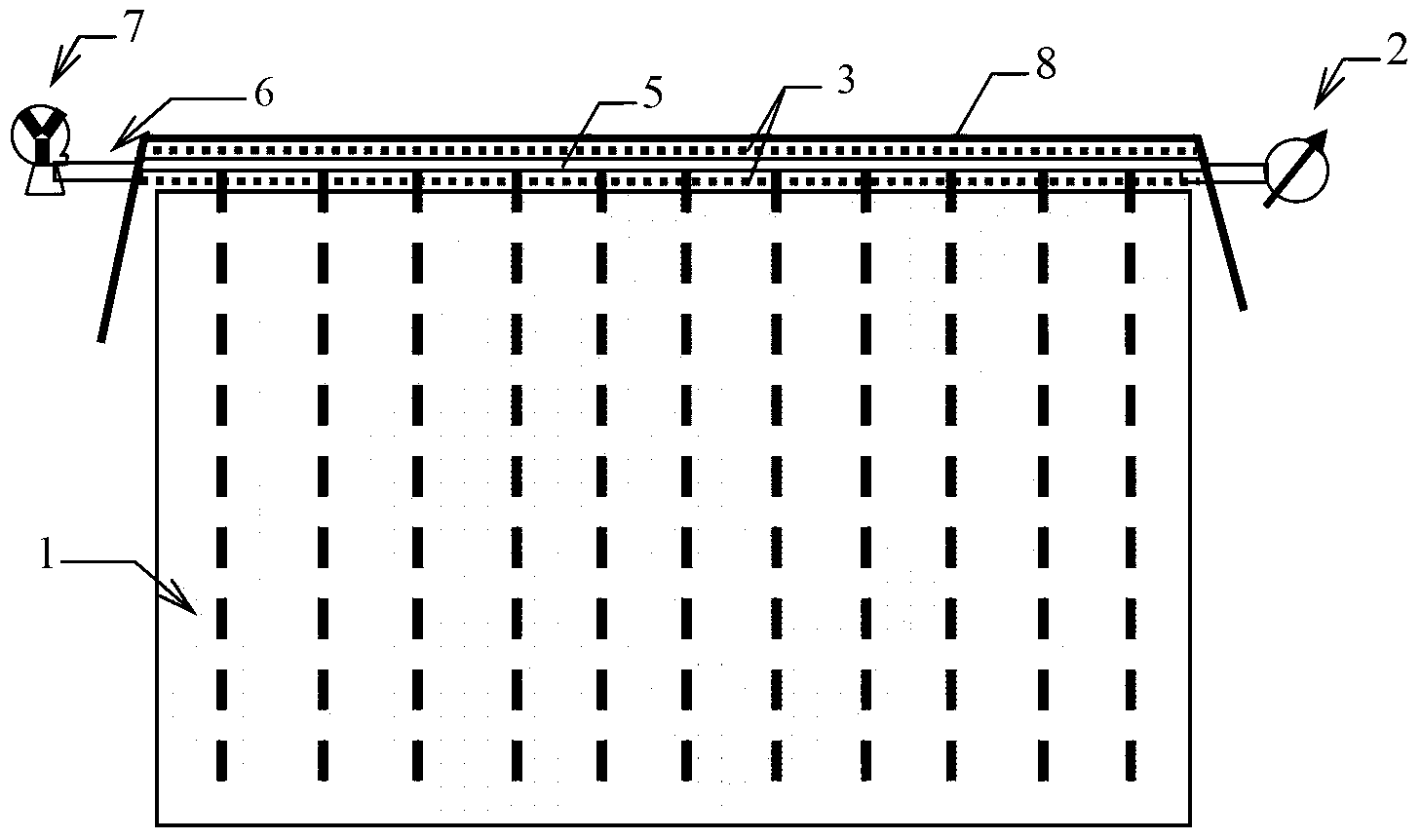

[0039] The anti-blocking controllable negative pressure rapid consolidation method of fluid dredging silt in this embodiment was implemented in a newly dredged river dredging silt yard with a test area of 8000m 2 (80m×100m), the specific steps are as follows (see Figure 1 to Figure 6 ):

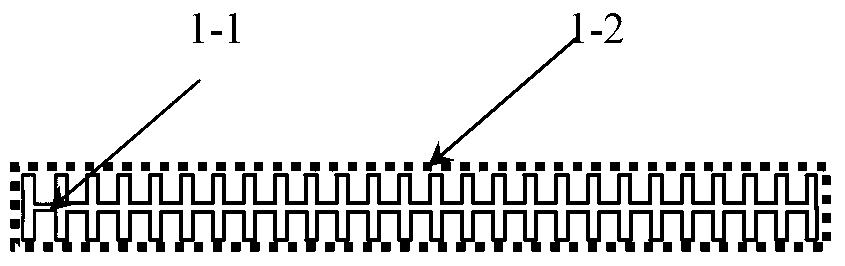

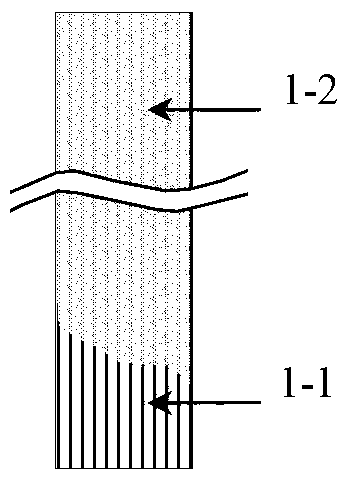

[0040] (1) Determine the design parameters of the anti-blocking drainage board 1 and make the drainage board: take samples in the on-site reinforcement area, and determine the characteristic particle size d of the dredging mud according to the measured results of the dredging mud particles 85 =25μm, according to the most effective pore size of anti-clogging filter material O 95 and characteristic particle size of dredged silt d 85 Relationship: O 95 / d 85=3~4, to determine the effective pore size of the drainage plate filter membrane O 95 =80μm, when processing the anti-clogging filter membrane 1-2 of the drainage plate, the manufacturing process of the flat monofilament structure is ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com