Rubber ring for gasket

A technology of rubber rings and gaskets, which is applied in the direction of engine sealing, engine sealing devices, machines/engines, etc., can solve problems such as large stress, and achieve the effect of reducing stress and inhibiting peeling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

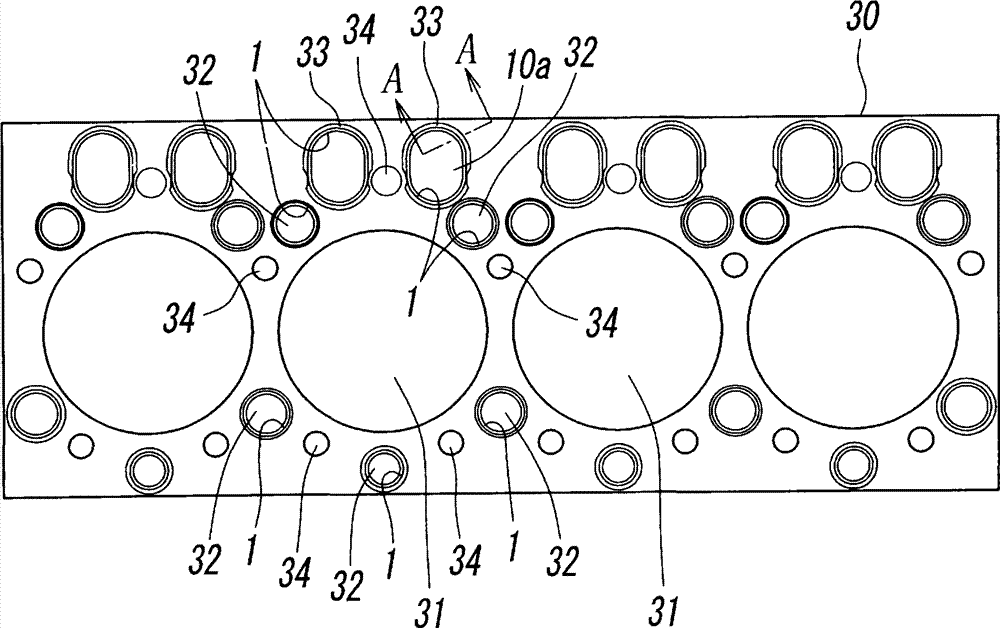

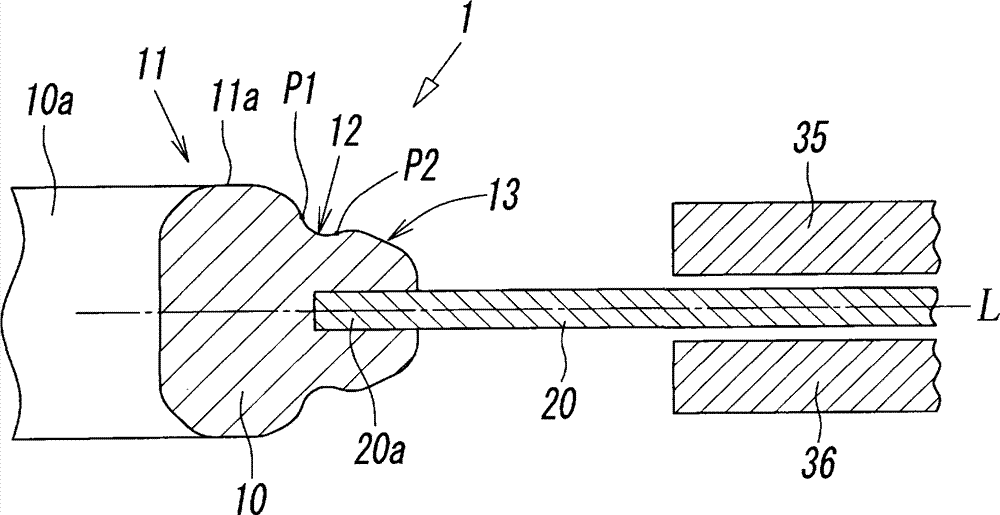

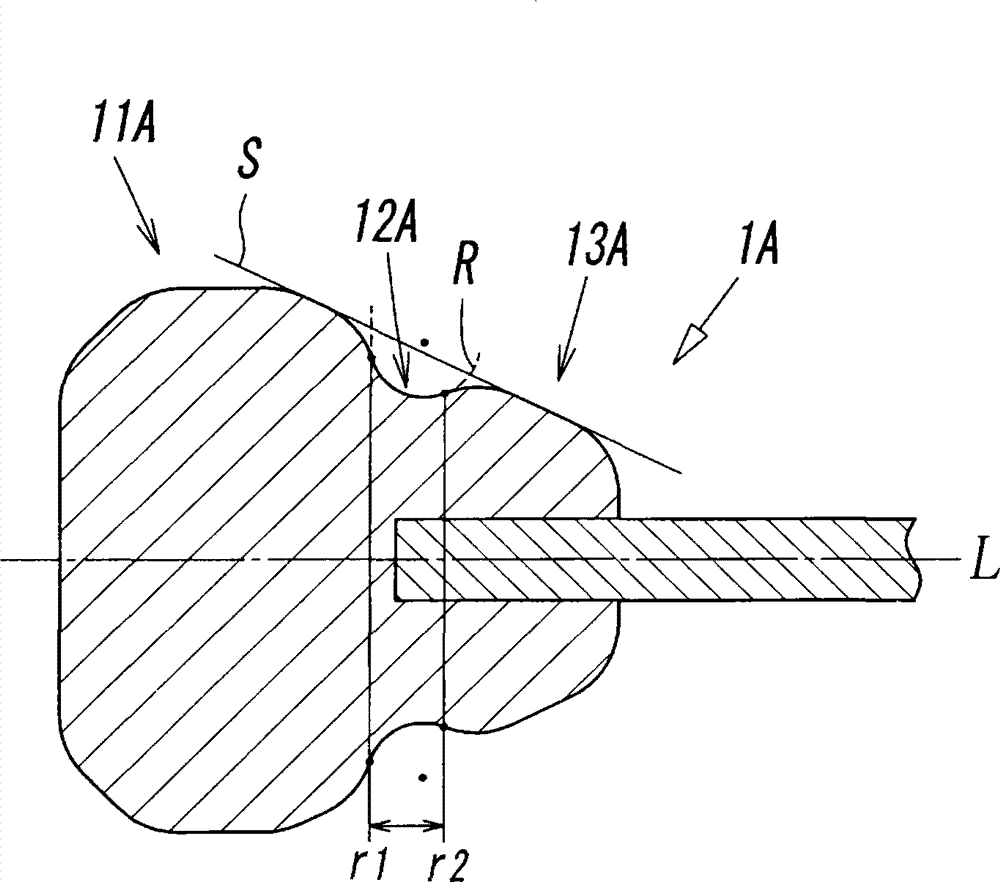

[0037] figure 1 shows a gasket 30 having the rubber ring 1 for gaskets of the present invention, figure 2 It is a figure showing the structure of the main part of the said rubber ring 1 in enlarged cross-section.

[0038] figure 1 The gasket 30 shown is a member provided between the cylinder block and the cylinder head in order to improve the sealing performance between the cylinder block and the cylinder head in an internal combustion engine such as an automobile. A combustion chamber hole 31 is provided at a position corresponding to the combustion chamber, and a water hole 32 for passing cooling water and an oil hole 33 for passing oil are arranged around the combustion chamber hole 31 . In addition, there are bolt holes 34 for inserting bolts that tightly connect the cylinder block and the cylinder head. The gasket 30 has two gasket plates 35, 36 having approximately the same shape on both upper and lower sides (see figure 2 ), the rubber ring 1 installed on the ga...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com