Method for monitoring sand carrying effect of drilling fluid

A drilling fluid and cuttings technology is applied in the field of monitoring the sand carrying effect of the drilling fluid, which can solve the problems of inability to circulate, high pump pressure, and large drilling friction, and achieves prevention of drilling engineering accidents, accurate measurement, and safe and reliable manufacturing. cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] In order to further understand the invention content, characteristics and effects of this patent, the following examples are given, and detailed descriptions are as follows in conjunction with the accompanying drawings:

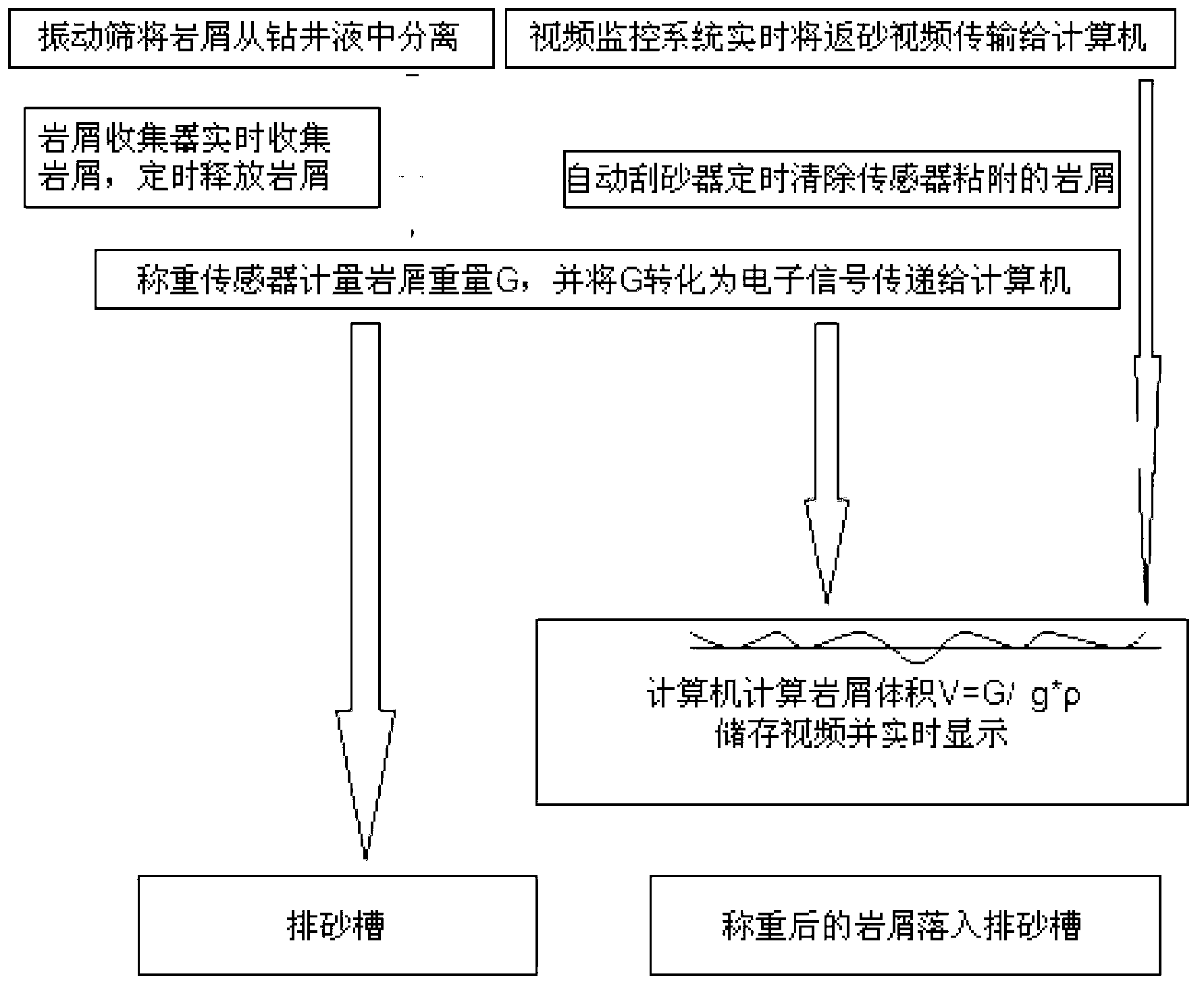

[0017] see figure 1 , a method for monitoring the sand-carrying effect of drilling fluid, which sequentially includes the steps of collecting cuttings, weighing the cuttings, and the steps of data transmission, storage, calculation and display,

[0018] The step of collecting cuttings is to separate the cuttings in the drilling fluid by the vibrating screen and collect them by the cuttings collector. The collected cuttings need to be fully separated by the vibrating screen. If the data is not fully separated or even when the drilling fluid runs out of slurry, it will be invalid data. .

[0019] The step of weighing the cuttings is to calculate the weight G of the cuttings by the weighing sensor. The weighing sensor adopts a piezoelectric sensor. also...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com