Liquid crystal display device, manufacturing method thereof, and electronic device

A technology of liquid crystal display device and liquid crystal layer, which is applied in the directions of optics, instruments, optical components, etc., can solve problems such as reducing brightness drop, and achieve the effect of reducing loss.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

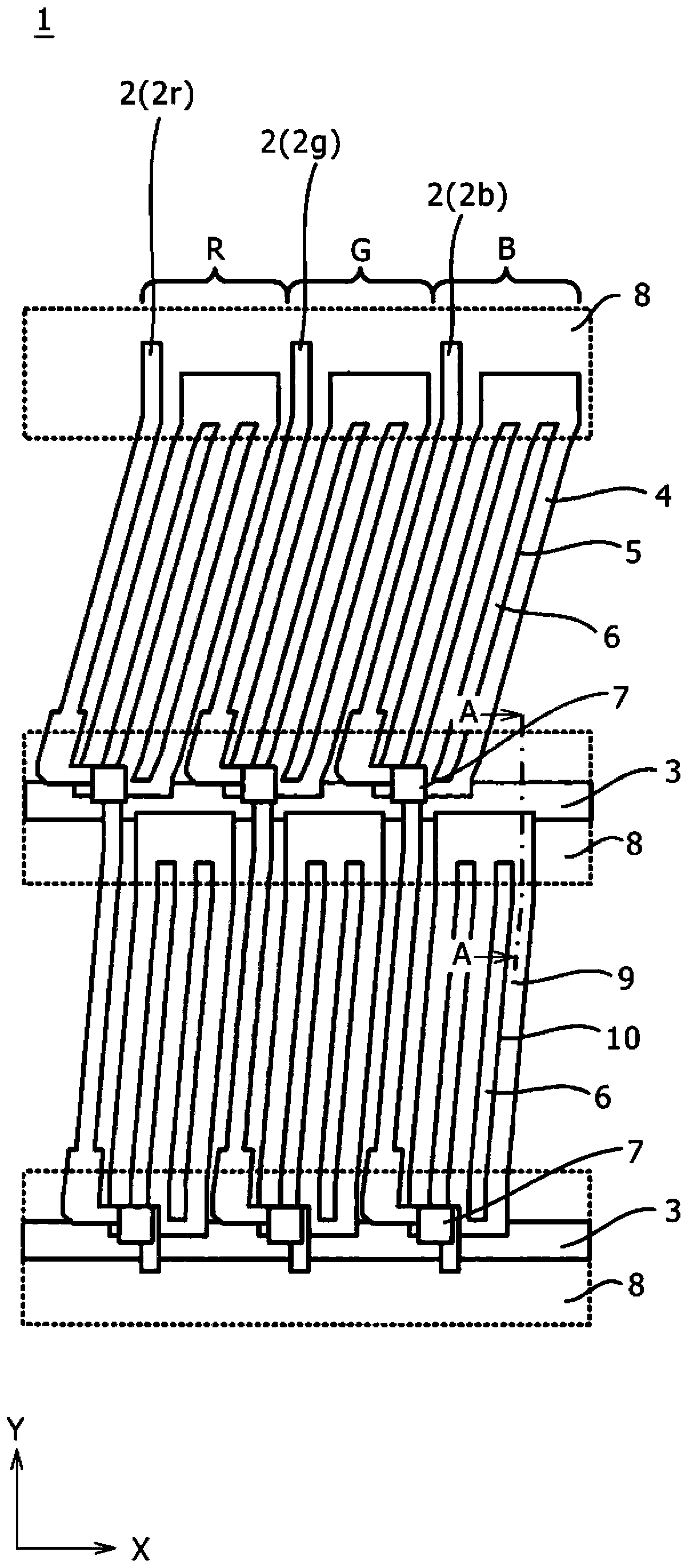

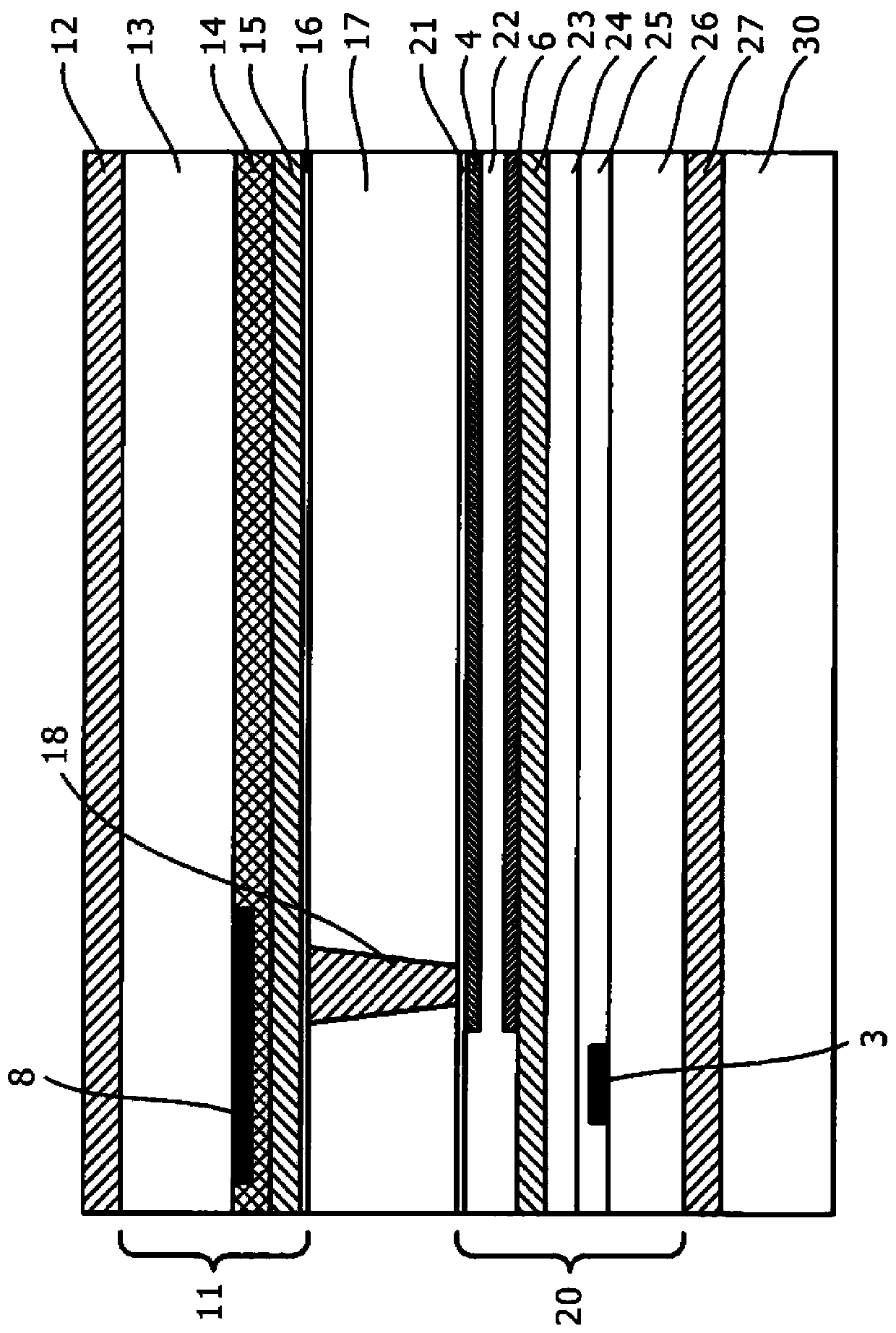

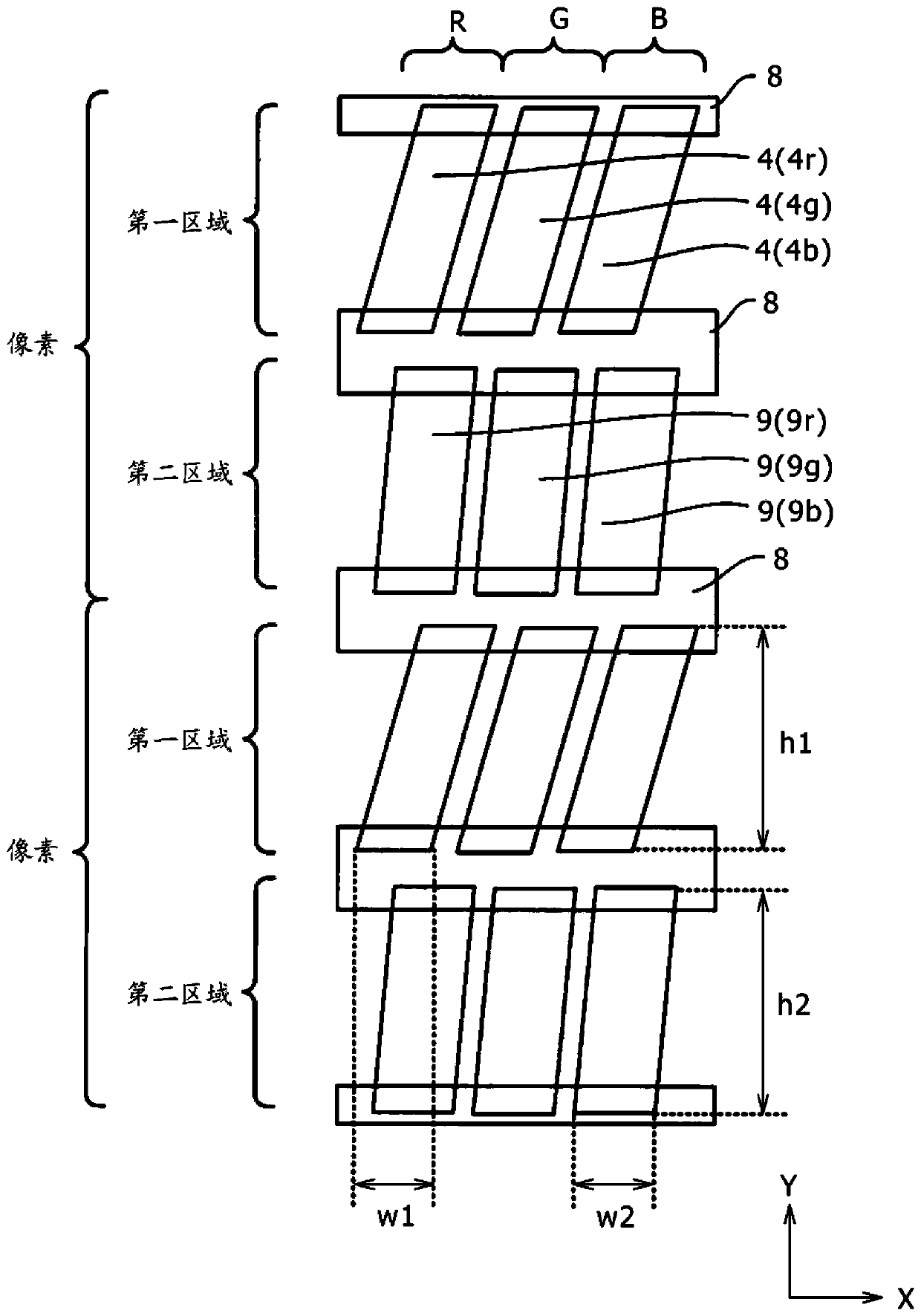

[0028] First, refer to Figures 1 to 3 A liquid crystal display panel according to a first embodiment is described. figure 1 is a schematic diagram showing a front view of a pixel of the liquid crystal display panel according to the first embodiment. figure 2 is along figure 1 A cross-sectional view taken along line A-A in . image 3 is a schematic diagram showing an alternate structure of regions constituting sub-pixels of the liquid crystal display panel according to the first embodiment.

[0029] The liquid crystal display panel (liquid crystal display device) 1 is a liquid crystal display panel of a horizontal electric field, and more specifically, a liquid crystal display panel of an FFS type. The liquid crystal display panel 1 includes a color filter substrate 11 and an array substrate 20 as a pair of substrates disposed opposite to each other. Each of the color filter substrate 11 and the array substrate 20 is made of a transparent member such as glass or plastic a...

no. 2 example

[0086] Figure 9 is an appearance perspective view showing an example of a television set according to the second embodiment. The television set 100 has, for example, a video display screen part 102 comprising a front panel 103 and a filter glass 101 . The video display screen section 102 includes the liquid crystal display panel 1 according to the first embodiment.

no. 3 example

[0088] Figure 10A and 10B is an appearance perspective view showing an example of a digital camera according to the third embodiment. Figure 10A is a three-dimensional view of the appearance viewed from the front side of the digital camera, while Figure 10B It is a perspective view of the external appearance seen from the rear side. The digital camera 110 has, for example, a flash section 112 , a display section 113 , a menu switch 114 , and a shutter button 111 . The display section 113 includes the liquid crystal display panel 1 according to the first embodiment.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com