Carbon emission recursive analysis method for non-standard structure variation process

A non-standard structure, recursive analysis technology, applied in special data processing applications, instruments, electrical digital data processing, etc., can solve the problems of affecting carbon emissions, affecting the carbon emission performance of products, etc., to achieve easy carbon emission information reuse and low carbon emissions. improved effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

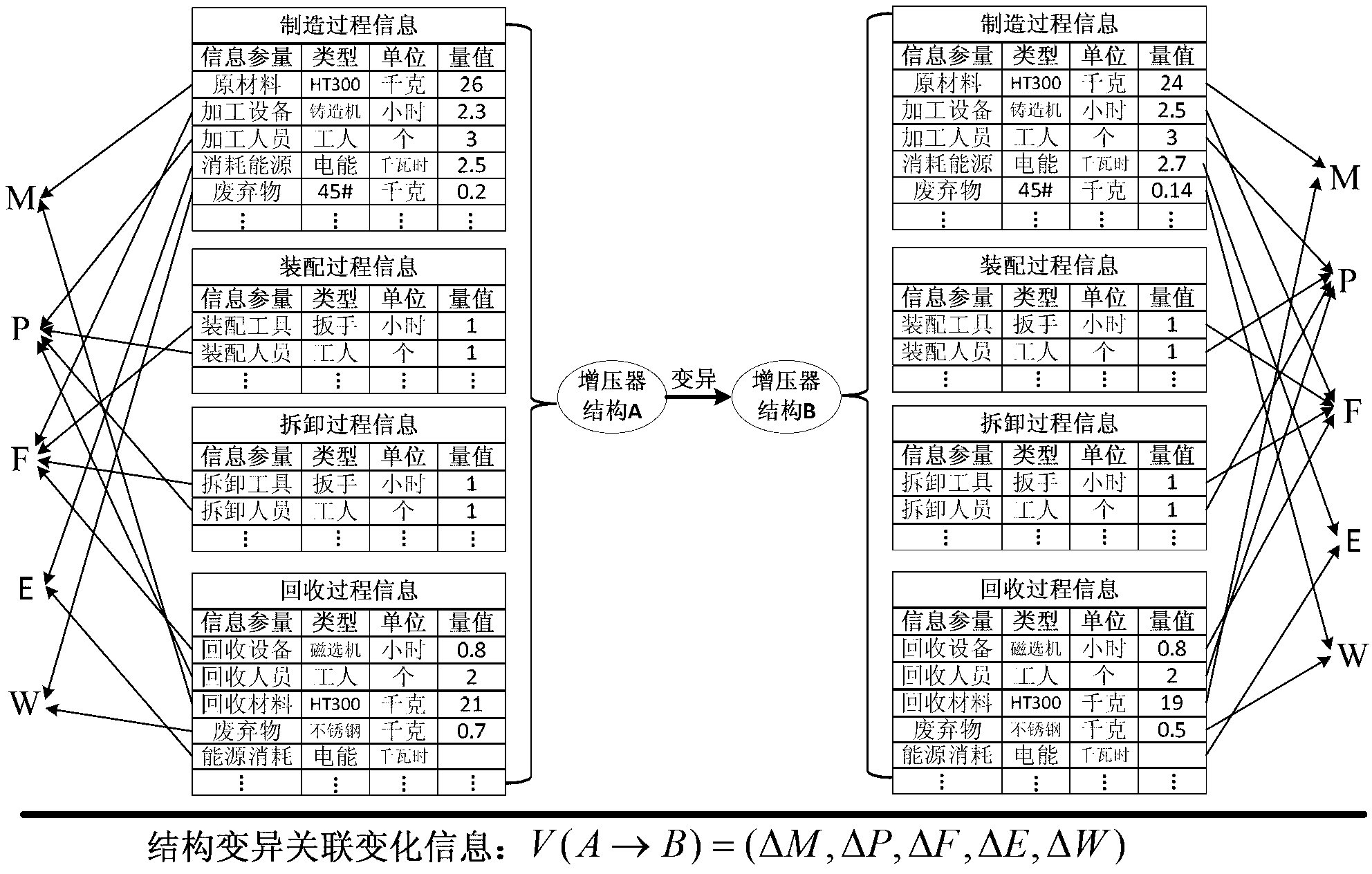

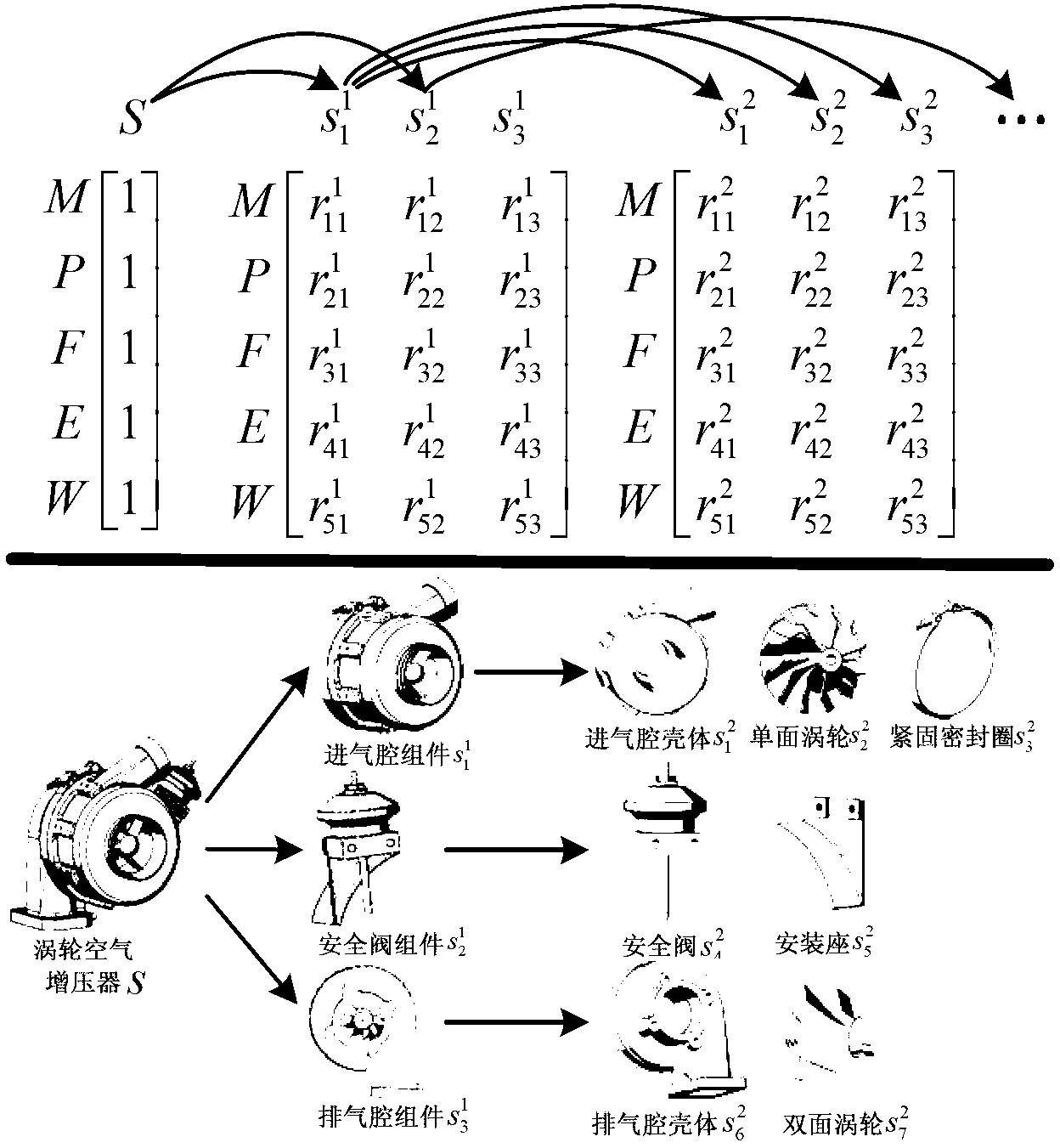

[0037] The present invention will be described in further detail below in conjunction with the accompanying drawings and examples, and the information involved in the figure is the actual application data of the present invention in the design of a turbo air supercharger.

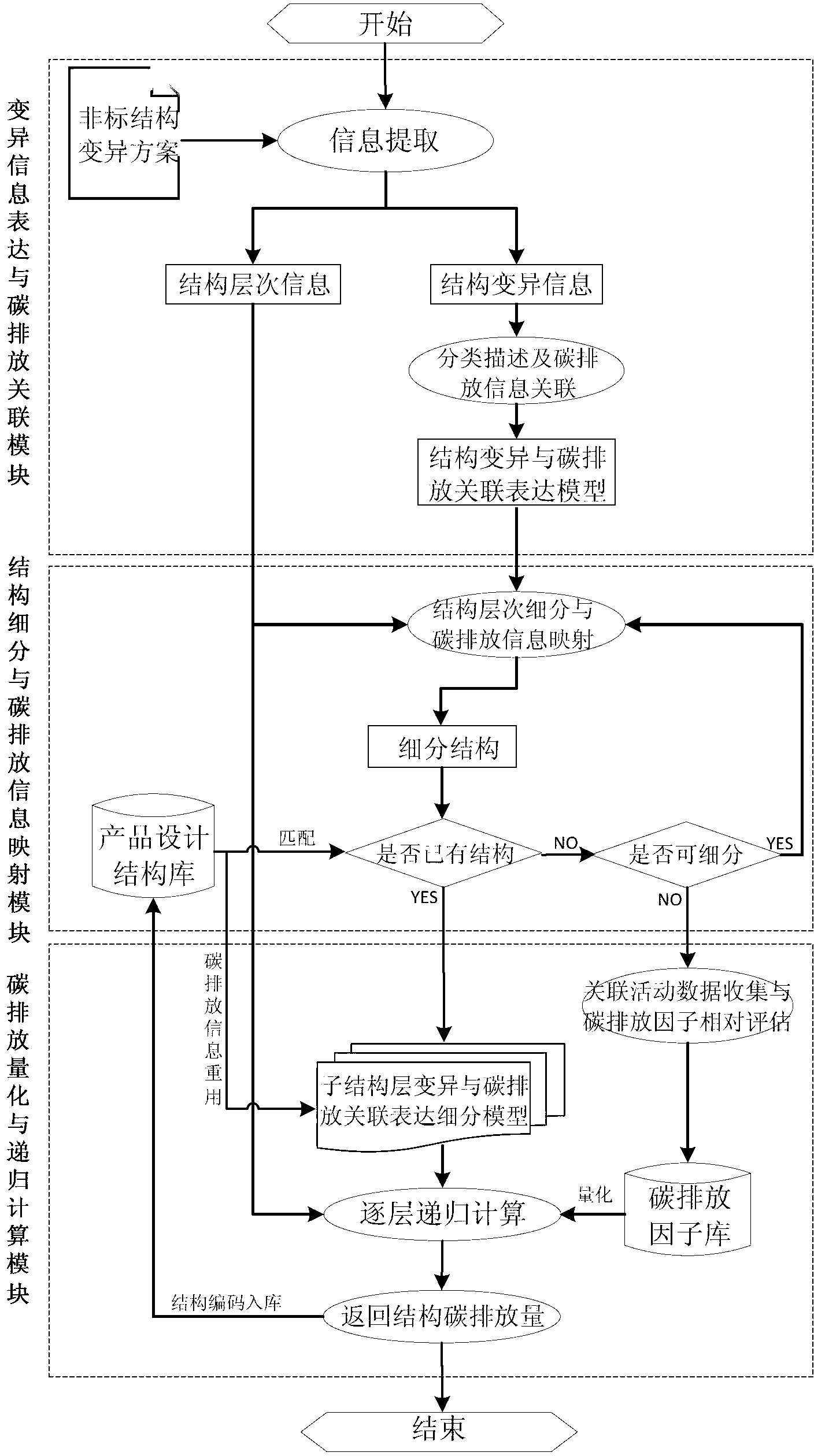

[0038] Such as figure 1 Shown is a general flowchart of the recursive analysis method for carbon emissions in the non-standard structural variation process described in the present invention.

[0039] The carbon emission recursive analysis method in the process of non-standard structural variation is supported by the enterprise structure design database, and a knowledge base including product design structure database and carbon emission factor database is established. The main process includes: classification expression of non-standard structural variation information and carbon emission correlation , Structure layer by layer subdivision and carbon emission information mapping, carbon emission quantificati...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com